Choosing acid-alkali-resistant gloves

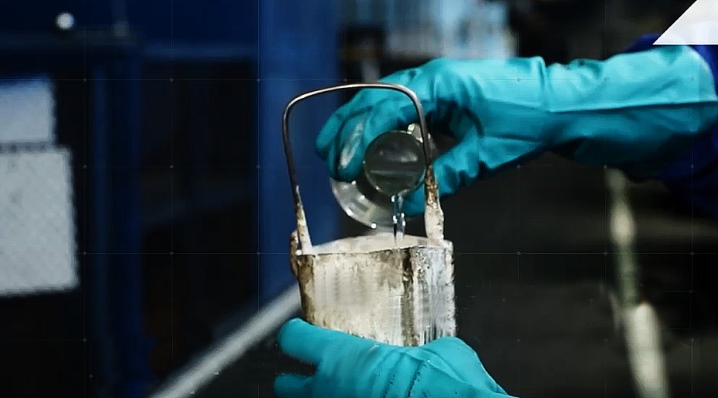

Working with chemicals is very dangerous and requires a certain level of protection. In addition to special clothing, special gloves are needed - acid-alkali-resistant. Consider their features, varieties and scope.

Peculiarities

The conventional designation KShchS (decoding - acid-alkali-resistant) indicates the resistance of objects to the action of highly aggressive and chemical substances. Acid-resistant PPE is not only hand protection, but also protective clothing. The mandatory parameters of protective equipment include waterproofing.

KShchS gloves are used when working with acids and alkalis, salts and chemical compounds. Thickness ranges from 0.35 to 1.2 millimeters, but thicker can be found. The maximum thickness (1.2 mm) allows you to work with highly concentrated acids - up to 80%. The gloves are made of rubber and latex, these materials provide complete protection. The products have a two-layer structure, and some models have an additional insulating layer. There are two types of KShchS gloves.

- For packaging, distribution and handling of various objects, the coating of which contains hazardous substances. The thickness of such gloves is 0.6-1.2 millimeters. Protection against chemical solutions 80% concentration.

- For jobs that require precision. Should be 0.35-0.5 millimeters thick and protected from solutions of 20% concentration. Safe operation time - up to 4 hours.

The type of work performed depends on which protective gloves it is better to opt for. For oil and petroleum products, MBS gloves are suitable - oil-resistant or nitrile. Nitrile is an artificial rubber. Gloves are made of HB material, doused with PVC (nitrile), they are quite thin, durable and heat-resistant, at temperatures from -20 to +130 degrees they do not lose their working properties.

MBS gloves are divided into two types - with incomplete drenching (no protective coating is applied to the back, but only covers the palms and fingers) and with a full shower - nitrile coating is applied to the entire surface of the glove.

Also among them there are short MBS models with fabric cuffs and full-flow gloves with elongated cuffs.

Varieties

The purpose of all rubber gloves is to protect your hands from harmful effects, dirt and abrasions. The main component in manufacturing is latex. In the names you can often see "latex" or "rubber" - these products are made from a similar material. Rubber gloves can be divided into three types - household, acid-alkali-resistant and dielectric.

Household ones are made of thin latex in one layer, they allow you to perform work where sensitivity is needed. They have a corrugated surface - this allows objects to not slip out of your hands. Dielectric made from highly elastic, electro-resistant rubber, designed to protect against contact with electricity. There are two types: for work with equipment with a power of up to 1 kV and for work with a power above 1 kV. Acid-alkali-resistant in terms of performance are divided into two types, both are focused on protecting the skin of the hands from hazardous chemical elements, but each has its own specific nuances.

Type I (GOST 20010-93)

The large thickness of the material - from 0.6 millimeters - allows you to work with gloves for a long time - up to 8 hours, with acids and alkalis with a density of 80%.KSC I type will last a whole shift with continuous work or several shifts at intervals for a break for another activity. Acid-alkali-resistant gloves are produced from natural latex. They have two thickened layers. Upper (with the addition of an adsorbent composition) - protects against external damage, exposure to chemicals and has increased strength.

The inner is a soft material that does not cause irritation and allergies, most often it has a cotton coating. The advantages of the material include flexibility, tensile strength and long-term maintenance of protective qualities.

Among the disadvantages is the effect of temperatures. At low, the material becomes brittle, at high - it loses flexibility and becomes sticky. Due to the protein contained in the glove compound, it may cause an allergic reaction.

They withstand the effects of active substances - acids up to 80%, coloring elements, non-aromatic hydrocarbons, alkali compounds up to 80%, salts up to 80%, fats and oils of vegetable and animal origin. Convenient to use - the shape, made according to the anatomy of the hands, reduces stress when wearing gloves for a long time. The outer covering with a relief prevents objects from slipping out, the pair is made using volumetric molds for the right and left hands, provides a snug fit, the edge of the gloves in the form of a small roller gives resistance to tearing and adds comfort when donning.

Type II (GOST 20010-93)

The difference from type I gloves is that this type is used for activities requiring great precision, while the former are suitable for rough work. Like the first type, they are made of two layers of latex, but thinner - 0.3-0.5 millimeters. Resistant to acids up to 20%, aromatic compounds of organic chemistry and alkalis up to 20%, aliphatic alcohols, salts up to 20%.

To obtain latex products, the anatomical shape is coated with a saline solution and then immersed in latex. A chemical microreaction occurs - the contact of cations and rubber (latex) particles, a film forms on the mold. The strength of the KSC of type II is sufficient for 4 hours of continuous operation. Also, the advantages include protection against oil and fatty solutions of all types (these substances are not dangerous, but they belong to chemically active ones and are poorly washed off).

They do not allow contact of coloring elements with the skin, are durable and protect hands from external microdamages, and are waterproof.

Scope of application

Such gloves are used in various fields, a description of which you can find below.

Use of KSChS type I protective gloves.

- In aviation. For the process of assembling and connecting elements.

- In all branches of the chemical industry.

- In the processing of metals. Applying paints and varnishes to surfaces, making batteries, etc.

- In agriculture.

- Automotive and instrument-making enterprises. Work involves interaction with coloring pigments and electrolytes.

Type II acid and alkali resistant gloves are used in the following applications.

- In pharmacology. Manufacturing functions involve the creation of drugs, employees come into contact with chemical compounds that harm the skin deprived of protection.

- In the automotive industry. During work, there is a mandatory contact with oily liquids and some number of acids.

- In the chemical industry. Manufacturing and its mixed industries are the main structure where PPE is needed. Employees dealing with highly aggressive conditions must be fully equipped with overalls, and gloves are an obligatory part of the industrial kit.

- In agricultural production. This area of activity also includes work with the use of toxic chemicals, for example, the production of fertilizers, the manufacture of drugs aimed at controlling parasitic pests and the decontamination of technical installations.

How to choose?

According to GOST, the length of the gloves must be at least 30 centimeters. When buying protective equipment, you need to pay attention to the packaging, which indicates the conditional letter designation of the sizes:

- S - the smallest of the size range, suitable for women with a small palm;

- M - size for an average female hand;

- L - for a large female palm;

- XL is the size for men.

Acid-resistant and alkali-resistant type I protective equipment has only 3 sizes in the line, which are determined by the width of the palm - 110, 120 and 130 millimeters.

KSC type II have 7 dimensions - 88, 100, 101, 107, 108, 119 and 126 millimeters. Certain rules will help to choose the right manufacturer of KShchS protection, this will not only ensure safety, but also make the work comfortable.

- The quality of the material - you need to pay attention to the material from which the gloves are made.

- Types of work performed.

- Cuff shape - elastic band fits snugly, but does not protect the arm above the cuff; leggings - have a great length, but sit freely.

- Production temperature.

- The presence of an inner layer - high quality gloves must have a second layer.

The comment was sent successfully.