What is a dowel screw and how to fix it?

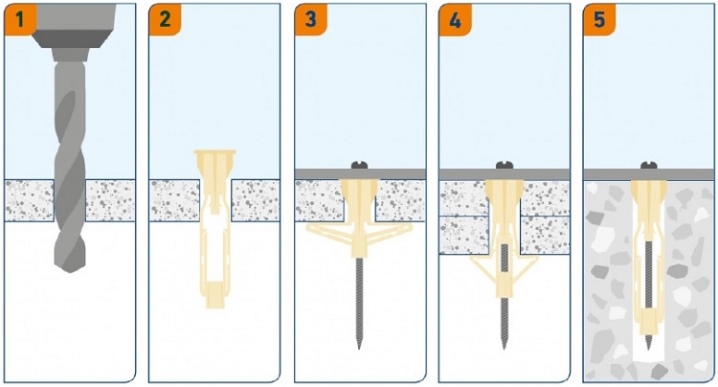

The dowel screw is an element for fastening structures made of various materials: stone, timber, brick, concrete and others. A self-tapping screw is selected for each material. Below we will talk about the features of fasteners, types, materials, size and weight, as well as the possibility of fastening to various surfaces.

Peculiarities

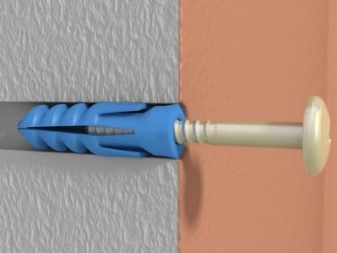

A dowel screw is a fastener for structures that has special antennae for fixing to the surface. When spaced with a screw or screw, a frictional force arises, which holds the dowel in the structure and prevents it from turning. Dowels are made from different materials, they can have different weights and sizes. Depending on the material of manufacture, self-tapping screws have their own characteristics. For example, polypropylene products do not withstand low temperatures. They are not recommended for outdoor use. Nylon elements are versatile. They can be used both outdoors and indoors.

The dowel can be with a retaining collar. The screw is made from nylon and is used for external installation work. Its peculiarity lies in special stoppers. They prevent the self-tapping screw from falling into the hole.

Self-tapping screws without a collar also have their own distinctive feature. The product is made of polyamide, and it has a through hole with longitudinal ribs and a non-expansion top. The structure of the product makes screwing in the screw much easier and increases the expansion force. The unbreakable top protects the surface from cracking due to its immobility.

It should also be noted that such the dowels are resistant to weather conditions. They can be used for outdoor facade work. There are types of dowels for a construction gun. The products are practical, effective and securely fix parts to the surface.

All fasteners are manufactured in accordance with GOST. Some specifications are subject to change. These include weight, diameter, length, structure. But the basic rules must be strictly followed. Manufacturers strictly adhere to the following GOST standards:

- material of manufacture;

- min and max are the curvature index of the rod;

- protection from a galvanized layer - galvanizing is carried out in compliance with the rules of galvanizing and passivated technology (coating thickness - 6 microns);

- diameter of washer and metal rod.

It is worth familiarizing yourself with the numerous types of products and their properties.

Species overview

Dowels are divided into the following types.

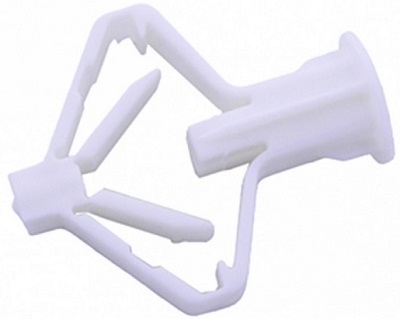

- Dowel "butterfly" used in working with thin materials. The cut element goes through the wall. When screwed in, it opens up. The self-tapping screw is equipped with a special cuff that prevents turning. The fixing of the structure is strong and reliable.

"Butterflies" are divided into subspecies: for solid solid and hollow soft walls.

- Self-tapping screws for facade connections. Used for fixing thermal insulation materials. Structural spacers have a reinforced collar with an edge. Thus, the soft thermal insulation material does not slip and is securely attached. Manufacturing material - polyamide with a high degree of impact strength.

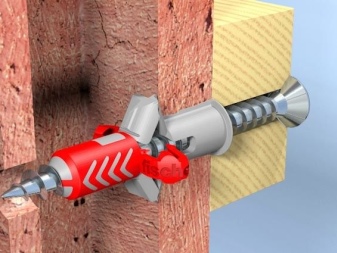

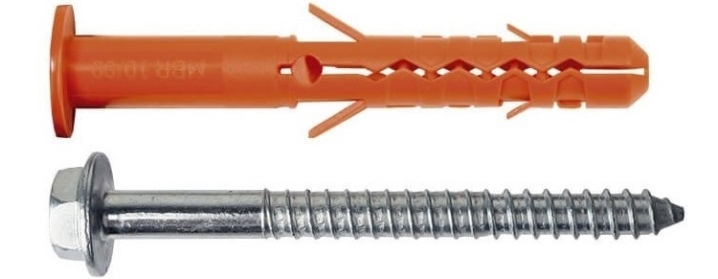

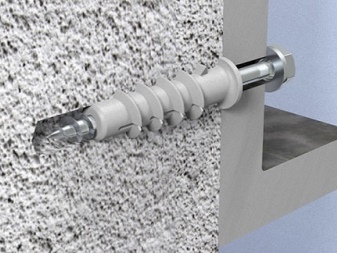

- Dowel-anchor. The product includes several elements: a bushing with a spacer and a rod. The rod is screwed into the sleeve, the slots are expanded, and rigid fixation occurs. The dowel is suitable for working on hard surfaces.

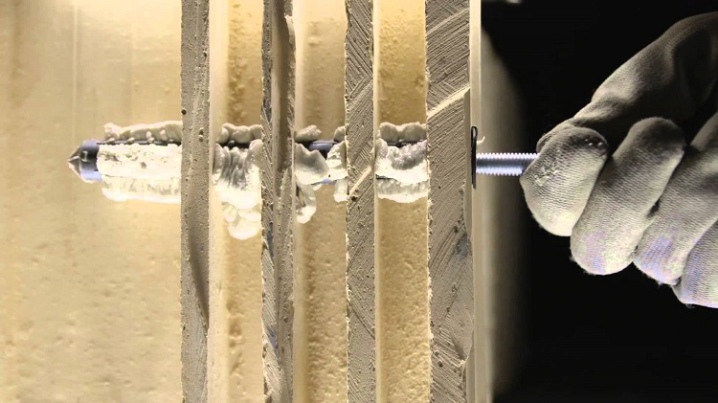

- Injection dowels-anchors. This is a chemical type of screw designed for fixation in porous material.The product has an adhesive composition. It exits the cartridge and fills the drilled hole. The work process is carried out using a construction gun or syringe. Cartridge volume - up to 800 ml.

- The ampoule plug also belongs to the chemical type. The ampoule is placed in the hole, after which a steel rod is screwed in. The ampoule shell dissolves, the glue is distributed. Then air enters the hole. Curing occurs, which provides a secure and rigid fixation. Synthetic resin is used as an adhesive.

Installation work using such dowels is quick and easy.

- The self-adjusting screw is used for fastening wooden products... During installation work, no additional pads or wedges are required.

- Universal dowel used for working with walls of any thickness.

- Nail dowel has a special nail with a thread-like edge. The reverse cone element provides a firm fixation of products to the surface.

- Dowel clamp used in the field of fixing cables, wires and installation of corrugated pipes. The design is a plastic strip up to 1 cm wide. The strip can be of various shapes. At the end of the product there are teeth that prevent the product from turning inside the surface. This way, you can be sure that the wires will not be pulled out by the gust of wind.

- Dowel "molly" made of galvanized steel. The self-tapping screw is used when working with drywall, hollow bricks and blocks. With the help of a dowel, pictures, mirrors, shelves, wall lamps are attached. When fixing the structure, the self-tapping screw opens and increases the reliability of the fastening. The peculiarity of the "molly" is the even distribution of the load.

Materials (edit)

Dowels are made from various materials, which have their own characteristics.

- Polyethylene products have heat-resistant properties. The viscous material holds its shape perfectly, does not crack or crumble.

- Polyamide self-tapping screws have a fairly long service life. Provides secure and rigid attachment.

- Nylon dowels are used for interior decoration. The material breaks down quickly at low temperatures. Therefore, its use is excluded for outdoor installation.

- Metal dowels-screws are strong and reliable. During the manufacture, a certain amount of zinc is mixed with the metal. This exposes the product to the appearance of corrosion, therefore, metal screws must be coated with a special anti-rust compound. Products have a drill and threaded spacers at the end. Thus, there is no need to pre-drill the hole. Installation of products takes place by screwing self-tapping screws into the surface.

- Plastic products are used for fixing in drywall or porous concrete surfaces.

Plastic products also provide a secure attachment to gypsum fiber sheets.

Dimensions and weight

Product marking includes diameter and length. The standard size of the screw dowel is 6x60 mm. Product weight - 0.91 g. Dowels measuring 6 by 35 mm have a mass of 0.70 g. Other dimensions and weights are presented below:

- 6x30 mm - 0.60 g;

- 6x40 mm - 0.72g;

- 6x80 mm - 1.1 g;

- 8x60 mm - 1.68 g;

- 10x50 - 2.09 g;

- 10x100 mm - 5.05 g;

- 12x70 mm - 14.01 g;

- 14x70 mm - 5.32 g;

- 20x100 mm - 10.35 g.

Versatile and spacer models are available in a wide range of sizes. There may be 3 or more lengths per diameter. Products with dimensions of 6x30 mm, 10x50 mm, 6x37 mm are considered as running dowels.

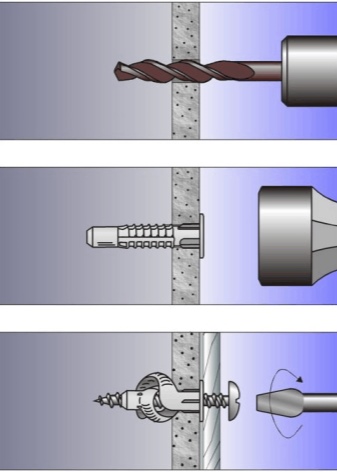

Fastening to various surfaces

Dowels are used to install curtain rods and ebbs. For work, they take products with locking collars that prevent full passage through the surface. Nail dowels are used when repairing skirting boards and for fastening window frames before using foam. When fixing the frame, it is necessary to take into account the ratio of the non-spacer and spacer parts.For drywall, it is better to use plastic or metal screws. Plus, these screws are great for quick installation. There is no need to pre-drill the wall. At the end of the products there is a drill and a thread. To mount the self-tapping screw, use a screwdriver that screws the dowel into the surface.

The dowel "butterfly" or "molly" is used for fastening to a plasterboard surface, since the self-tapping screw expands only in a complete void. Plastic and metal dowels are suitable for fastening to foam concrete. For fixing large-sized products with a large weight, polyamide dowels are chosen. They have a through hole and a top without spacers. Screwing in a self-tapping screw is quick and easy. The thrust increases. Due to this, the structure is able to withstand a lot of weight.

To install TVs and air conditioners, it is recommended to use standard dowels that come with the fasteners... The products are already designed for the weight of the device. The only caveat is the base of the material. If the equipment is mounted on a brick or concrete wall, then there will be no problems with fixation. To install chandeliers and sconces, it is better to use long self-tapping screws with reinforced spacers. Corrugated dowels are able to withstand the weight of massive chandeliers when installed under stretch ceilings.

For heavier structures, anchor dowels are used. They are equipped with several parts - threaded bushing and spacer. The spacer is screwed into the sleeve. The thrust force is increased, due to which a reliable and rigid fastening is carried out.

Anchors are not used for installation in aerated concrete or shell rock. The surface will burst when struck.

For the repair and installation of pipes, it is better to use a dowel-clamp, which has a special screw for fixing. It is also used for fastening wires.

During repair and installation work, you cannot do without dowels. The choice of screws depends on the material of the products and the surface on which the structure will be attached. Each type of self-tapping screw has its own characteristics, weight and size. This article introduces the reader to the characteristics of the screws, will help determine the choice of dowels for a particular material.

In the next video, the types of dowels and their application are waiting for you.

The comment was sent successfully.