Everything you need to know about stud screws

In the modern market of fasteners today there is a wide selection and assortment of various products. Each of the fasteners is used in a certain field of activity, when working with certain materials. Today, a stud screw is in great demand and widespread use. It is about this fastener that will be discussed in this article.

Peculiarities

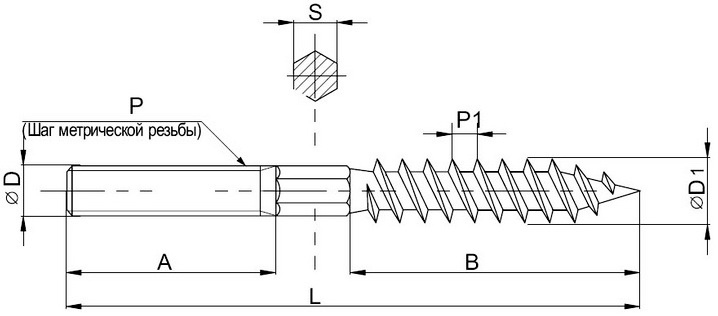

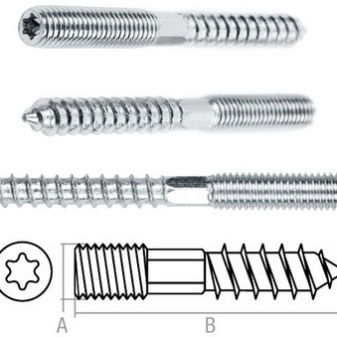

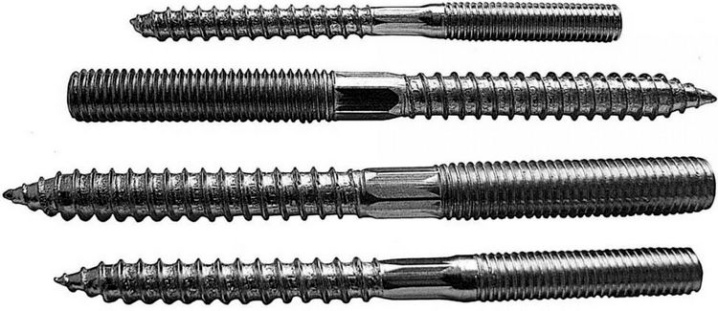

A stud screw is often called a screw or a plumbing bolt. Its design is straightforward. It is a cylindrical rod that consists of two parts: one is presented in the form of a metric thread, the other is in the form of a self-tapping screw. Between the components there is a hexagon, which is designed to grip the stud with a special suitable wrench.

All stud screws are manufactured in accordance with the requirements of regulatory documents. Each manufacturing enterprise that is engaged in the production of this product must be guided by such documents as 22038-76 and GOST 1759.4-87 “Bolts. Screws and studs. Mechanical properties and tests ".

According to these regulatory documents, the stud screw must be:

- durable;

- wear-resistant;

- resistant to various negative influences;

- reliable.

One of the most important product criteria is long service life. To achieve all the above parameters, only high-quality materials are used for the manufacture of fasteners that have excellent physical and technical properties.

The production uses high-quality steel, the strength class of which is not less than 4.8. The finished product is treated with a special zinc coating, which improves its properties. The presence of a zinc coating on the surface helps prevent corrosion.

The plumbing pin is characterized by the following parameters:

- screw diameter;

- screw length;

- coating;

- type of thread;

- metric thread pitch;

- screw thread pitch;

- turnkey size.

Each of these parameters is clearly stated in regulatory documents.

A prerequisite is laboratory tests, after which the product is applied marking... Its presence confirms the quality and technical parameters of the product.

Product marking is information indicating the accuracy class, diameter, pitch and direction of the thread, length, grade of material from which the fastener was made. Thanks to it, you can find out all the necessary information about the product.

Types and sizes

Today, manufacturers make many different stud screws, each of which is characterized by certain parameters and dimensions. You can familiarize yourself with them in detail by looking at the table.

Product type | Metric thread | Length, mm | Metric thread pitch, mm | Screw thread pitch, mm | Metric thread diameter, mm | Screw thread length, mm | Turnkey size, mm |

М4 | М4 | 100, 200 | 0,7 | 0,7 | 4 | 20 | 4 |

M5 | M5 | 100, 200 | 0,8 | 0,8 | 5 | 20 | 4 |

M6 | M6 | 100, 200 | 1 | 1 | 6 | 25 | 4 |

М8 | М8 | 100, 200 | 1,25 | 1,25 | 8 | 20 | 4 |

М8х80 | М8 | 80 | 1,25 | 3-3,2 | 6,85-7,00 | 20 | 5,75-6,00 |

М8х100 | М8 | 100 | 1,25 | 3-3,2 | 6,85-7,00 | 40 | 5,75-6,00 |

М8х120 | М8 | 120 | 1,25 | 3-3,2 | 6,85-7,00 | 40 | 5,75-6,00 |

М8х200 | М8 | 200 | 1,25 | 3-3,2 | 6,85-7,00 | 40 | 5,75-6,00 |

M10 | M10 | 3-3,2 | 8,85-9,00 | 40 | 7,75-8,00 | ||

М10х100 | M10 | 100 | 1,5 | 3-3,2 | 8,85-9,00 | 40 | 7,75-8,00 |

М10х200 | M10 | 200 | 1,5 | 3-3,2 | 8,85-9,00 | 40 | 7,75-8,00 |

M12 | M12 | 100, 200 | 1,75 | 1,75 | 12 | 60 | 7,75-8,00 |

It is imperative to take into account all the above parameters when choosing and buying a stud screw... You also need to understand that each type of product is designed for fastening certain materials.

In addition to these types of fasteners, there are others. More detailed information on each type of hairpin can be found at specialized points of sale. Today, you can buy a stud screw at absolutely any store that specializes in the sale of various fasteners.

Application area

The scope of the stud screw is quite diverse. This fastener used in various industries for fastening parts and different materials. But, probably, it's not a secret for anyone that most often the product is used in the plumbing industry.

Namely, in the process:

- fastening the clamp to the pipeline;

- fixing sinks and toilets;

- installation of various plumbing products.

You can attach plumbing elements and pipes (both sewer and plumbing) with a stud screw to any surface: wood, concrete, brick or stone. The main thing is to choose the right fastener.

In some cases, experts recommend using a dowel in tandem with a hairpin, so that the fastening is more reliable and durable.

For more information on how to tighten the stud screw, see the video below.

The comment was sent successfully.