Subtleties of leveling walls with plaster

It is quite possible for everyone to become a “master of himself” in the process of renovating a house or apartment, especially since this opens up room for creativity and allows you to significantly save on calling specialists. Finishing work after a careful study of professional advice and recommendations will certainly be within your reach. Even if you just need to paint the walls or stick wallpaper, the result may not please, and not at all due to the lack of preparation of the performer, but due to the fact that the surface is curved. It must be leveled, then the paint, and any other coating will fit perfectly.

Features of preparation

There are two basic alignment methods:

- drywall;

- plaster.

At the first, the walls are sheathed with plasterboard sheets. This method is sometimes referred to as dry plastering. The case moves faster, less dirt than when working with plaster.

There are significant drawbacks.

- GKL are more often mounted on a frame, and if the room is small, then an additional reduction in area will be critical.

- Hanging heavy objects (for example, hanging cabinets) on such a finish is possible only with the use of special fasteners to the main wall, there is a risk that the drywall will not withstand the load.

In the second method, special plaster mixtures are used. These materials are devoid of the disadvantages inherent in GCR. The technology for working with plaster is also not very complicated. The market offers a wide range of different mixtures, so you need to take into account the composition and scope of the material in order to choose the right one.

Types of plaster

There are clay, cement and gypsum plasters. Each has both positive and negative properties. Clay plaster is used less often than others, since it has two significant drawbacks: it dries for a long time (a layer of 5–10 cm dries up to 3 weeks), fragile (often cracks). But this mixture is very cheap, it can be made by hand, the only one of all plasters adheres equally well to any surface (wood, adobe, brick, concrete).

The problem of lack of strength is easily solved by adding cement. And for leveling walls with a large slope, such a mixture is perhaps the best option, with the condition of being applied to the shingles.

Cement mixtures can be divided into two types, such as:

- for a rough (first layer) coating - with a coarse sandy fraction;

- for finishing - with inclusions of fine sand.

The advantages of such plaster include low cost, quick preparation and ease of application of the solution, long service life of the resulting coating. The fact that the composition does not dry out very quickly allows even a novice master to work with it, but increases the time required for repairs. In addition, there is a risk of cracking when applying a layer thicker than 2.5 cm, in which case a reinforcing lining is required.

Gypsum plaster is a very popular material due to the following advantages:

- hygroscopicity - it absorbs moisture well, and if the microclimate is too dry, it can give it back;

- environmental friendliness and safety - safe for people, which is especially important for children and allergy sufferers;

- economical consumption - much less mortar is required than for covering the same area with other plasters.

The gypsum composition hardens faster, which can be considered both a disadvantage and an advantage, because a certain skill in handling the material is required, but the time for doing the work is significantly saved, you only need to prepare the mixture in a small amount. Plaster-based plaster is more expensive than others, but if we take into account the economy of consumption, then the difference will turn out to be insignificant.

Which is better?

It is possible to give a definite answer to this question only if all the conditions for the use of the material are taken into account. For the main (rough) coating with a strong curvature of the walls, a clay mixture may be the best option. If the deviations are not very large, cement or gypsum plaster can be recommended. In this case, the decisive factors will be the price and the preparedness of the employee. And of course, the location in which the work will be carried out is of great importance.

Scope of application

For living rooms, any composition of the customer's choice is suitable. When decorating a nursery, gypsum-based plaster is the best option. For decoration of premises where high humidity is possible: kitchens, bathrooms, toilets - it is recommended to use cement mixtures. With plaster, you can level not only the walls, but also the ceiling. But recently, drywall has been used for this purpose. And they also carry out finishing according to the stretch ceiling technology, which does not require leveling the surface. The reason is that the application of plaster on a horizontal surface overhead is more time consuming than the other methods mentioned.

For the floor, the use of plaster mixes is not recommended; here it is best to use concrete or special mixes for screed.

Application process

There are two main ways to plaster walls, such as:

- alignment by eye using a rule;

- using beacon landmarks (landmarks).

The first method is applicable when the curvature of the surface is small. At the same time, plaster is thrown onto the prepared wall with a spatula and leveled with the rule, leading it from the bottom up along the surface. Having passed along the entire wall, with the rule of greater length, the surface is ironed again in different directions, carefully removing all irregularities. It should be noted that in this case, it is unlikely that it will be possible to achieve an ideal result. Therefore, such an alignment is done under wallpaper or other dense decorative coatings, but not for painting. And most often they are used for utility rooms.

The beacon method is used more often.

It includes several stages.

- Preparatory work. In order for the plaster layer to be strong and durable, the walls must be prepared. It is required to remove, if possible, all layers of the old finish. To decide whether to remove old plaster, you need to check if it has moved away from the wall, whether voids have formed under it. This can be determined by tapping the entire surface from floor to ceiling. If the sound is dull, then in this place the layer has most likely gone away and the old plaster should be tried to be removed, especially with a large area of such voids.

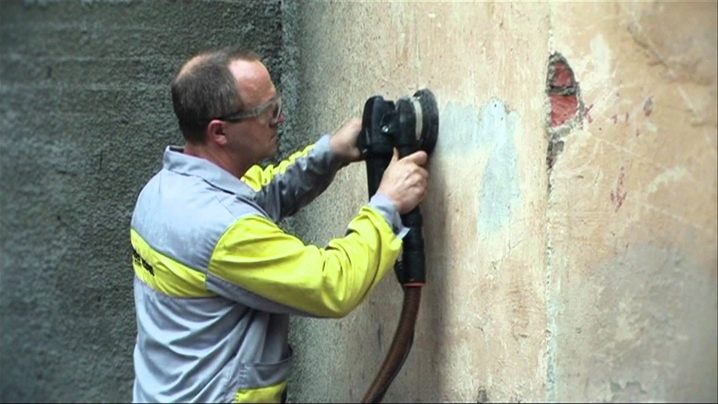

It is better to close up large visible irregularities immediately, cover the pits with putty. Try to knock down bulges. If the wall is finished with a too smooth compound, there is a risk of poor adhesion to the plaster. In this case, you need to make notches using a grinder (grinder) or a perforator, about 100 per 1 m².

- Primer. Surface priming is also carried out to improve adhesion. The choice of mixtures is wide enough and depends on what wall material it is intended for and what kind of plaster it can be used for. Usually on the packaging of the plaster mix you can read about the recommended primer. "Betonokontakt" and Cerezit117 are often used. Some formulations require additional moistening of the surface or thorough cleaning of dust, so you must read the instructions for them. Apply the primer with a roller, brush or spray gun.

For brick walls, instead of a special composition, it is permissible to use plain water. In this case, plaster immediately, without waiting for drying. When using primers, the drying time must be observed according to the instructions.

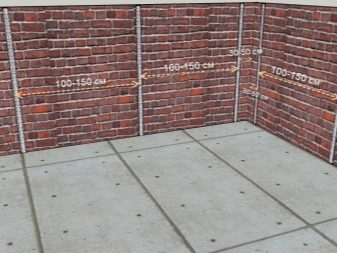

- Installation of beacons (fixing). For high-quality alignment, special guides are used, which are called beacons or landmarks. With the help of the level, the angle of deviation of the surface and the plane in which the beacons are exposed are verified. It is best to use special T-shaped metal profiles as guides. You can take wooden planks, but they must be even, and it is difficult to find such. The slightest distortion will ruin all the work.

First, the extreme beacons are fixed, stepping back from the corners no more than 30 cm.For this, it is better to use self-tapping screws or screws. First, the upper and lower ones are screwed in, then along the entire profile - at a distance of about 35–40 cm. The guides must hold tight and not move anywhere. Then, between the extreme beacons from above, below and in the middle, rope or fishing line is pulled. Focusing on the ropes, the following profiles are screwed at a distance less than the length of the rule, which will stretch the plaster solution. It is more convenient to move from the doorway if there is one on this wall.

The verticality of the guides is constantly verified by the level, thereby adjusting the depth of twisting of the hardware. For this purpose, you can also use a plumb line lowered from the upper screws.

Then the ropes are removed, the surface is once again cleaned of dust and plastering is started. Sometimes curbs made of the same plaster mixture that will be used in the future act as beacons. But in order to get a high-quality result, it will take much more time with this method, especially for an inexperienced worker.

- Plastering. The plaster mortar is prepared in accordance with the recipe on the package. The dry mixture is diluted with water in the recommended proportion, mixed with a construction mixer. Then the mixture is settled for some time and mixed again until smooth. The prepared plaster is thrown onto the wall with a spatula, starting from the bottom and moving up. You should get a fairly dense layer that does not cover the beacons. They do not equate him, because this is the basis.

When the first layer dries, the surface is moistened and the process is repeated, but after the strip is covered with plaster, it must be followed by the rule. The tool is applied perpendicular to the surface just above the lower edges of the beacons. The rule should be carried out from the bottom up, gently pressing, but not too hard, so as not to remove the plaster. Excess mixture from the tool is removed with a spatula and applied back to the wall. The surface is ironed with a rule until the mixture ceases to be captured and collected.

Then all the other strips pass in stages. It is important to take into account that when using gypsum plaster, the mixture for each stage is prepared in the required amount, it must be calculated accurately, since the remaining one quickly hardens and becomes unusable. The plaster layer should now be flush with the beacons. After waiting for complete drying, the guides must be removed. This is especially true of metal profiles, since if they are left in the plaster, rust may appear in the future, which will spoil the external decorative coating.

The grooves formed after the removal of the pins are filled with a plaster mixture of the same composition, and everything is compared into a single plane using a rule.

The gaps left around the floor, ceiling and other walls are also filled with plaster. An angled spatula is used to level and smooth the mixture in the corners. If necessary, you can put a third layer, which is usually no thicker than 2 mm.It is necessary to align window and door openings, as well as slopes with plaster in the same way, using guides on both sides of the surface, or, if the opening is not wide, one profile in the middle will be enough.

- Finishing treatment. When the wall is completely dry, the plastered surface is moistened again and finally smoothed out with a trowel or a special leveler. To strengthen the plaster layer, the surface is primed with a finishing compound.

To objectively assess the result of your work, you can compare it with the requirements of SNIP 3.04.01-87 "Insulation and finishing coatings", namely:

- deviation from the vertical should not be more than 1–3 mm per 1 m;

- for the entire height of the wall, the maximum deviation should not exceed 5-15 mm;

- on 4 m² of area - no more than 2-3 irregularities with a depth of no more than 2-5 mm.

Tips & Tricks

It is worth adhering to several recommendations of experts when leveling walls with plaster.

- When preparing the solution, it should be borne in mind that a thinner plaster adheres better, but has a flowing effect, a thick one can form a thick layer, but its adhesive properties are worse. Therefore, it is advisable to observe the proportions of dry mixture and water specified in the instructions as accurately as possible.

- If the work takes place in damp rooms, there will be no unnecessary treatment of the walls before priming with an antifungal solution.

- To make the corners smoother, before you start plastering the second wall, you need to wait until the first is completely dry.

- If you do everything right with your own hands, following the instructions, the result will be the pleasure of a job well done and the repair will be much cheaper.

How to align the walls with plaster along the beacon profiles, see the video below.

The comment was sent successfully.