Lime plaster: pros and cons

Traditionally, lime plaster is used for construction and surface finishing, which has not lost demand throughout its existence. It is used for interior decoration, as well as for leveling and protecting any surfaces. Lime mortars are warm, but not as strong as cement.

Peculiarities

Experienced people know that building mixes are used for smoothing interior surfaces and exterior finishing of buildings. Thus, they protect the surface from the negative effects of natural factors, and the use of a solution turns the finishing into a comfortable and short-lived procedure.

Lime plaster is prepared either before finishing work, or they facilitate the process and get ready-made mixtures. It is enough to simply dilute them with water in a certain ratio.

If you want to prepare the solution yourself, you need to know its composition, which includes the following components:

- lime;

- water;

- river sand.

Advantages and disadvantages

The advantages of lime plaster are due to a number of factors.

- High adhesion capacity, and this property does not depend on the raw material from which the surface to be treated is made. Finishing is especially successful on stone and wood surfaces. It can be concluded that lime is a versatile material for construction.

- After the mixture has hardened, high plasticity appears, due to which there is no risk of cracking.

- The ability of the solution to "breathe" and high vapor permeability guarantee a favorable indoor climate.

Along with the indisputable advantages, lime has some disadvantages:

- After carrying out repair work, after several days, you will notice that the surface has acquired irregularities. This minus is easy to eliminate if you follow the advice: since the solution is applied in several layers, you need to wait a while after the first layer, and only then proceed to the second. Usually the time depends on the type of solution. For some options, it is enough to wait an hour, and for some - a day.

- The disadvantage is the lack of sufficient hardness of the applied composition. It is important to know that after a while, the plaster will acquire sufficient hardness, and it will be possible to drive in nails.

- Before starting work, there is a need for a primer or a simple spray. It is prepared as follows: cement with lime is mixed until a creamy consistency is formed. But after spraying, you must wait up to 10 hours for the mixture to harden.

- The protective effect against the appearance of mold and mildew is achieved due to the bactericidal properties of the material. Even with high humidity in the room, there is no risk of the appearance of microorganisms.

- Affordable plastering price.

- High plasticity of the solution, as well as ease of application during work. This makes it possible to do repair work with your own hands in the absence of the necessary experience.

- The use of lime plaster on a wooden surface will protect the wall from various rodents and insects.

Views

Thanks to the combination of lime with other components with those positive characteristics that are not present in lime, it became possible to obtain solutions with improved performance characteristics.

Such substances include cement, clay, and gypsum. Clay as an additive to the mortar will add durability to the coating, but it dries quickly, so in no case should the mixture be prepared in advance. PVA glue, in the amount of 2% of the total volume of the solution, helps to speed up the hardening process. It increases the viscosity so that the coating resists all external factors. Colored additives increase the vapor permeability of the surface, and the prepared dry mixture can be used for further repairs.

Gypsum allows the mixture to set quickly, while the wall is very smooth.

Based on the component added to the mixture, there are several types of lime mortars:

- Lime with the addition of sand is used for rough finishing of ceilings and walls. But this type of mixture is used for indoor use, since it does not have sufficient strength. It cannot be applied to the gypsum surface - peeling parts will appear.

- Lime with cement is a complex solution, it contains more than two components. Together with cement, sand is contained in the solution. This mixture is highly durable and is used for finishing all types of surfaces. This type of mortar is considered an excellent option for rough work such as facade decor and painting. The mixture is often used for operation in high humidity conditions.

- Lime with the addition of gypsum is used for interior finishing works with a moisture level of no more than 60%. It is used for walls made of wood, plaster, stone. The limitation is concrete: it interacts with gypsum and forms layers.

- Lime with the addition of clay is used to strengthen the internal walls.

If the ratio of binder and lime is not correct, the mixture is often either too oily or too skinny. If the mixture turns out to be oily, this means that there is more binder in the solution than necessary. As a result, the surface of the wall is covered with cracks. If the solution is lean, then this indicates a lack of lime, which leads to the destruction of plastic properties and the acquisition of low strength.

At the same time, the surface is not subject to cracking and shrinkage.

Application area

Plaster is used to decorate buildings that will later be painted or wallpapered. Decorative plaster with an original texture and colored relief is used for finishing the facades of public buildings. For residential buildings, this solution is rarely used. Plasters with special protective additives protect against water and guarantee warmth in residential buildings.

Lime mortars with the addition of cement are used to plaster walls in buildings where there is a high level of humidity. Lime mortars with the addition of gypsum and cement are recommended for use only indoors in dry rooms. Clay lime plaster is used to decorate wood and stone walls in rooms with low humidity levels.

Preparation of the solution

Preparation of plaster lime for work includes several stages.

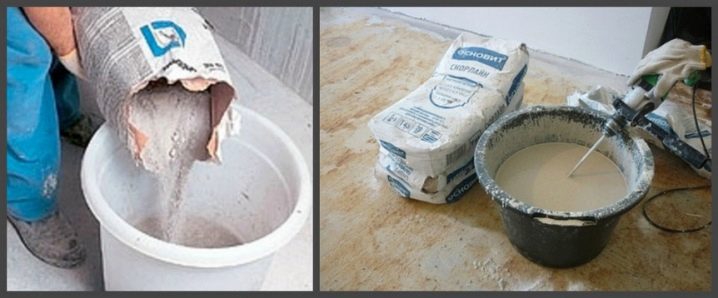

At the first stage, you need to decide on the type of solution so that its properties are suitable for a specific surface. For self-preparation of plaster, you need to take into account the sequence of actions - preparation of a single dry mixture from the components, followed by dilution with warm water in the required proportions. You can mix the components in any container. However, the bottom of the dishes should be even. This is because lime will settle to the bottom due to its poor dissolving capacity.

The result will be a huge overspending of the raw materials used, and a poor consistency of the solution.

Next, a pre-sifted sand layer is poured along the entire perimeter, and lime is laid out on top. Then the composition is mixed until a homogeneous consistency is formed.At the last stage, it is necessary to fill in several layers of lime, and, adding warm water, mix thoroughly.

Preparation of the first layer of plaster: add 0.2 parts of lime and 2.5 parts of sand to one part of Portland cement. The second layer is prepared by adding 0.2 parts of lime and two parts of sand to a part of the cement. To prepare the third layer, you should take 1 part of cement, 0.2 parts of lime and 1-1.5 parts of sand.

For high-quality mixing of all components of the mixture, special drill bits are usually used. This method allows you to simplify and speed up the process of preparing lime mortar. Do not forget that to prepare a high-quality mixture, you should adhere to the exact proportions, and add water gradually, stirring until the composition is uniform.

The quality of the surface and the final result depend on the correct application of each layer of lime mortar. Subject to the necessary proportions and technology for performing finishing work, you can make repairs yourself and significantly save money.

Application Tips

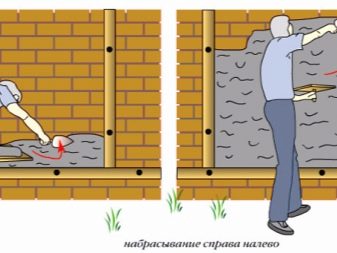

Lime plaster is applied to the surface in three layers. This is the most important condition for obtaining a quality result.

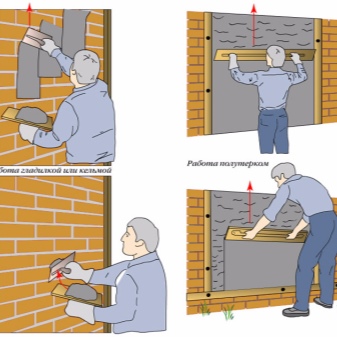

The first layer, called spatter, improves the adhesion of the first layer to the base of the wall. For this layer, the consistency of the solution is not prepared too thick. The mixture is poured over the entire surface with trowels, without further leveling. A certain amount of spray should be collected on the trowel and swept with a brush at close range. If you swing it hard and sweepingly, then a large amount of the mixture is sprayed without hitting the surface.

The second layer is soil. It is considered the main layer and has a thickness of up to 50 mm. The solution for it is prepared thicker than when sprinkled. The mixture is applied to the surface with trowels or smeared with trowels, since its consistency allows it. Excess soil is removed with a plastering cutter. After the end of this stage, it is necessary to check the horizontal and vertical uniformity of the application ..

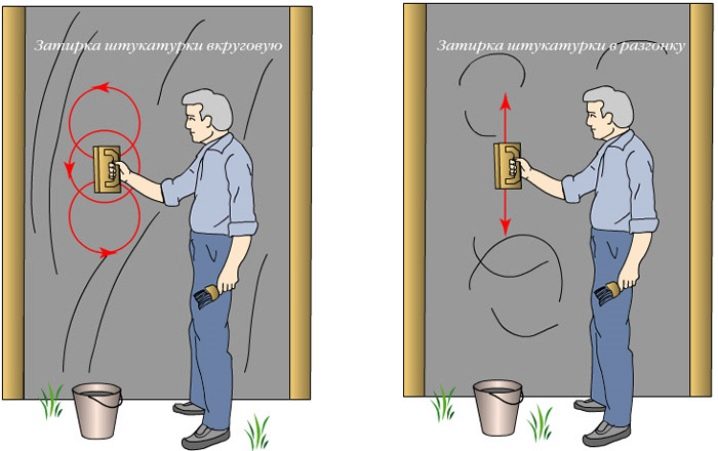

The third layer is used to eliminate defects, small chips, smoothing and getting a flat surface. The mixture is prepared with the same consistency as for the spray application and applied to a damp surface a couple of millimeters thick. Then the surface is rubbed with a special device - a grater designed for grinding. If the soil has time to dry, then you can wet the surface with a brush.

The use of lime plaster allows you to significantly save money and make high-quality repairs.

You will learn even more about the application of plaster in the following video.

The comment was sent successfully.