Marking calipers: device, types, tips for choosing

The most famous tool for accurate measurements is a caliper, it is simple and at the same time allows you to make measurements, the error limit of which does not exceed hundredths of a millimeter. One of the varieties is a marking caliper (ShTSR), intended both for determining linear dimensions and for marking surfaces with great accuracy.

Principle of operation

This device is designed in the same way as a conventional caliper. It has a bar - a hard alloy rail with a scale of divisions applied to it. A sliding frame is attached to the rail, which can be moved along the bar. The marker caliper has 2 carbide-tipped jaws - one of them is motionless, represents one of the ends of the bar. The other is on the frame and moves with it.

The part to be measured can be clamped between the jaws, while the frame is fixed with a special screw. Usually the caliper has one more pair of jaws designed for taking internal dimensions.

Some models are equipped with a depth gauge that allows you to measure the depth of holes, grooves and grooves. The most important element of the device, due to which the measurement accuracy is achieved, is the reading device.

The simplest option is vernier, which is a regular scale of divisions applied to one of the edges of the frame slot. Instead of a vernier, the reading device can be a watch-type dial or a special computer. The layout version of the device has a design identical to that described, and a few more features.

- Circular wiring system. This device is needed for convenience when carrying out marking work.

- The material of the jaws is of increased hardness and their pointed shape, which allows marking on metal and increases accuracy, minimizing deformation of the jaws.

The main technical conditions are determined by GOST 166-89. The most important characteristics to consider when choosing are as follows.

- Measurement range. Calipers with carbide jaws 250 mm, 300 mm and 400 mm are among the widest range of tools in this category.

- Acceptable margin of error. Depending on the range and accuracy class, it takes values from 0.05 mm to 0.1 mm. For models with a large range (1000 mm and more), the error can reach 0.2 mm.

Digital calipers are more accurate than mechanical calipers.

At the same time, instruments of both types require calibration (setting the zero mark), protection from contamination, and skewing of the frame in order to avoid loss of accuracy.

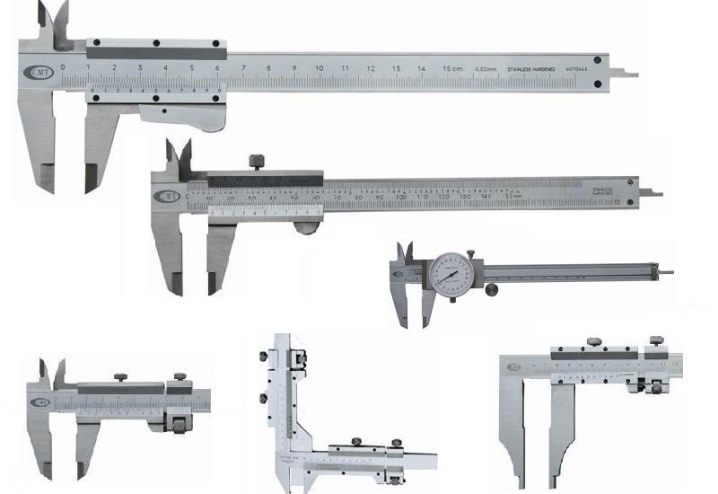

Varieties

When choosing a specific type of measuring device, it is logical to take into account its cost and own needs. There are three main types of calipers on the market.

The simplest and cheapest models are vernier. They have 2 scales, one of them is applied to the frame, as in the design described above. To determine the linear dimension, you need to fix the jaws in the desired position (they must squeeze the measured part or fit snugly against the inner edges of the hole, groove, groove), and then take measurements. The division on the bar, which turned out to be to the left of the zero position of the vernier, shows how many millimeters the measured length is. To determine the fractional part, you need to multiply the ordinal number of the first risk on the vernier that coincided with the main scale by the price of its division. Then add the first and second values.

In order not to perform this operation with every measurement, you can buy a caliper with a dial. It will allow you to see the value immediately, by the position of the hand on the hour scale. The two described modifications are mechanical. Both are durable and highly accurate. From time to time it is necessary to check whether the zero of the vernier (or the arrow of the dial) coincides with the zero of the bar with the jaws closed. If not, the device is not calibrated.

In addition to these varieties, there is a third type - electronic calipers. A special computer with a sensor with a fixed discrete step (usually 0.01) is responsible for counting the distance between the jaws. These models are more accurate, they are calibrated with a single push of the electronic scale reset button to zero. But they are more expensive and have a shorter lifespan. They require periodic battery replacement.

For domestic purposes, a mechanical vernier caliper may work for you, while a digital instrument is good for more professional measurements.

There are several more special cases of device design that you can consider if you have specialized measurement and layout tasks. For example, models with extended jaws for measuring internal hard-to-reach areas or for determining center-to-center distances.

How to choose?

If you want to choose the caliper that works best for you, look at quality first. Among the best manufacturers of these tools are - Swiss brand Tesa, Japanese Mitutoyo, German company Mahr... In the domestic market, the Chelyabinsk Tool Plant (CHIZ) and the Kirov Tool Plant (KRIN) are trusted.

It is worth taking into account the functional features of each of the models. There is a standard configuration of the device, it is marked by the manufacturer with a special designation ШЦ-I. This is a simple version with two measuring jaws. If you need to make measurements, for example, of the diameters of holes, pipes, any internal dimensions, it is better to opt for ШЦ-II with an additional pair of jaws designed just for this.

Models with a dial (dial) are marked with ШЦК markings. If you are not looking to buy the cheapest version of a caliper, then it makes sense to choose one of them, because working with a dial is easier than with vernier divisions. If your goal is to buy an expensive instrument with the highest accuracy rates, then the SCC digital device is suitable for you, with which you can perform measurements and markings with an accuracy of 0.02 mm.

Choose a tool with the optimal rod length depending on which range you are going to measure.

There are compact models for sizes no larger than 20 cm, but if you want to take accurate measurements, say, during construction, you can buy a specialized caliper with a rod length of up to 1 m or more. Just keep in mind that it may have a larger measurement error.

Finally, do not forget about the specifics of the surface that the caliper will be used to mark. Steel used in mechanical engineering, titanium and various cemented carbides are difficult to mark with conventional tools. You can choose a model with the ShTsT marking - with jaws made of an alloy of increased hardness. They can be subjected to higher loads without the risk of damage.

Many are concerned about the question of whether there is a danger of getting a marriage or a fake. The chance that this will happen is reduced to zero if you buy or order the tool in the official store of the brand. It is quite different if you buy from a supplier without a dealer license. Maybe they sell cheaper, but in this case, the products may indeed be counterfeit. The same applies to many cheap Chinese caliper models.When buying, be sure to check whether the frame moves easily, whether it gets skewed, whether the zero on the vernier (or the arrow on the dial) corresponds to the beginning of the main scale with the jaws closed.

How to convert a regular caliper into a marking caliper, see below.

The comment was sent successfully.