All about the methods of dipping sheet piling

Information on the methods of immersing sheet piles will take more than one volume of practical experience and scientific developments, instructions on methods and methods of use. However, the most popular devices make construction activities much easier, especially on difficult soils. A vibrator with additional devices is available only to large construction companies, but it can be rented.

Where is sheet piling applied?

The scope of application of devices for immersion in the ground depends on several conditions: the material of the sheet pile, the nature of the soil and the intended purpose of the fence being built. In choosing the subject of preference, the basic factor may be the required immersion depth, the climatic features of the region and even the size of each element of the fence, as well as the method of fastening its components.

The main differentiation is made according to the material used in the manufacture of the sheet piling.

- Wooden tongue - one of the oldest varieties, but still not lost its relevance due to the cheapness of the material and its prevalence, the relative ease of installation, which does not require the use of special equipment. Scope of application - pits with a depth of no more than 3 m. As a component of the fence, logs and boards can be used, the predominant method of immersion is indentation.

- Steel - a more expensive, but also more durable sheet pile can be in the form of steel pipes or a metal profile of a specific shape (Larsen sheet pile). Here, piles are often driven into complex swampy soil or with an abundance of groundwater.

- Sheet piles made of polymeric materials are driven into the soil by indentation or vibration.

- A combination of several methods is allowed when installing reinforced concrete piles with strength and tendency to cracking at the same time.

The scope of application (in the field, urban conditions, on the bank, sliding into a river or sea) depends on the type of installation used. Vibrational ones are differentiated in frequency and force, pressing systems have variable designs, hammers for hammering can operate on mechanics, diesel, air and hydraulics.

Description of vibration immersion

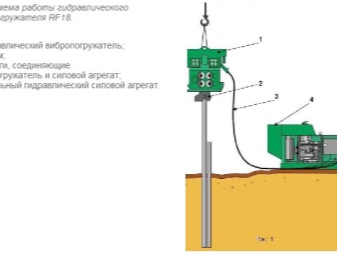

Vibrator is the general name for any type of device used in the process of driving piles using vibratory driving. It is a working unit with variable features and characteristics. The developer chooses a suitable one, guided by its scale, the selected type of sheet pile and additional devices for its work, which will ensure maximum efficiency, suitable for the selected type of sheet pile and the type of soil where the immersion will be made.

This is the most popular type, since indentation is suitable only for soft and loose soils, the shock method cannot be used near architectural monuments and old buildings in the city, and the vibration method is not suitable only for rocky and dense cohesive soil types. Each tool has three basic elements:

- a special device for generating vibrations (vibrations) called a vibration exciter;

- an energy producer for its start-up and work (of various types, the electric one is powered by an electric motor, but there is also a hydraulic motor and other design features);

- headgear - to transfer movement from centrifugal force to the tongue.

The rotation of imbalances in different directions causes vibration, a force arises that acts on the attachment axis between them, the headgear transmits movement from the unit to the tongue, and it gradually sinks into the ground. Differentiation of devices is carried out according to several characteristics. By vibration frequency (normal, high-frequency and resonance-free), by mobility or by the optimal type of additional device (manual, with an electric motor, for a crane or pile driver, low or high frequency, for an excavator powered by the hydraulic system of a construction machine).

Speed and efficiency, low noise level, relatively low cost of work, excellent quality, preservation of the sheet pile and surrounding buildings - the undeniable advantages of vibrators. Of the shortcomings, only suitability is called not for all types of soil.

Dipping the sheet pile by driving

Technologically simple equipment was used for the first piles tested in construction. Among the shortcomings, they note the need to use energy-intensive installations, the possibility of damage to the sheet pile during the hammering process and noise during operation. There are several modifications with different properties. The latest developments allow to eliminate significant disadvantages and enhance the advantages of the method.

A modern submer of this type can be used on almost any type of soil, but it is not used in dense urban areas. Piling of sheet piles in construction companies is estimated to be more expensive than piling due to potential destruction and the need to select the necessary equipment for various types of fences, to fasten the sheet pile to produce accurate, directed impacts and constant soil measurements.

The main unit is a hammer, powered by various types of energy, which is also differentiated by mass, drop height and frequency of blows. It is mounted and moved on a copra, it consists of a base machine, a mast, struts and other parts, depending on the type:

- machine on wheels or tracks;

- the turntable is missing or available;

- a mast with a stipulated change in departure or inclination, without it or universal;

- if possible, use - simple, with an emphasis on the ground, semi-universal, with two stops.

What matters is the jig, which ensures the accuracy of the connection and is used to give a static position to the tongue. The correct one allows you to orient the hammer even to a small diameter of the fence or reinforcement part.

External or special application allows the use in a set for hydraulic engineering.

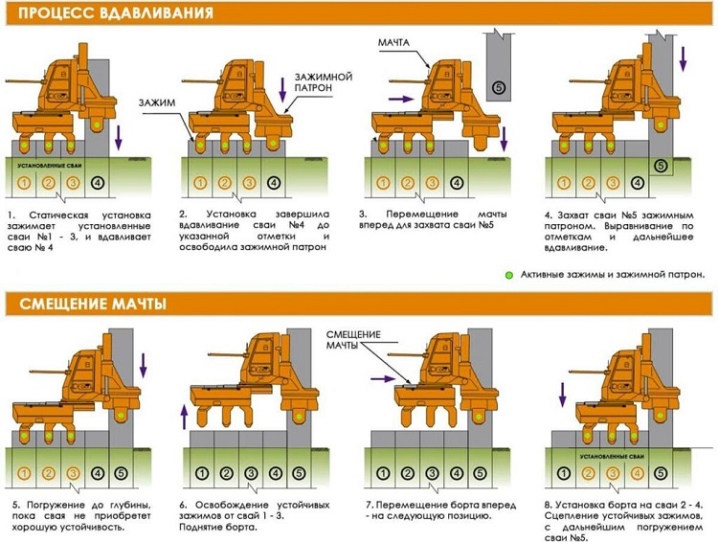

Indentation technology

In Russia, the method has been used since the late 90s of the last century, but protective structures in Western countries are mainly erected with its help. The indentation of the Larsen sheet pile, according to some experts in the construction business, is the most progressive and modern technology. The equipment allows construction to be carried out near dilapidated buildings and architectural monuments, in areas with a high population density. The application of the method allows you to work with little noise and avoid the destructive impact of a shock even near old, fragile buildings and in areas where there is a risk of landslide.

The indisputable advantages of indentation during the construction of fences include:

- wide scope of practical application;

- complete absence of vibration or shock loading, allowing you to work even in the area of the pipeline or subway lines;

- high speed of work on the construction of the fence;

- profitability - the budget is reduced due to speed and quality;

- evenness of sheet piling due to the same immersion process;

- control over work using virtual technologies and timely correction of shortcomings;

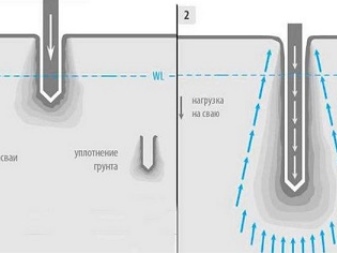

- environmental friendliness and an increase in bearing capacity by 10% in comparison with those established by the impact method.

New developments in this technology provide pressures ranging from 1000 kg to several tens of thousands. Of the shortcomings, the need to use heavy-duty equipment is noted. Its installation and use, even if it is a lease, increases the cost, as does the need to pre-prepare wells.

Each of the methods used has its own specifics, so the choice is made deliberately, taking into account all the necessary components. Cost is of great importance, but not only the cost and duration of the work is taken into account, but also the environment: clogging and vibration are impractical in densely populated areas due to the potential destructiveness in relation to old, fragile buildings.

There is a long-developed technology for work in water. The indentation allows you to build circular and corner configurations of sheet piling.

The comment was sent successfully.