All About Larsen Dowels

The beginning of the twentieth century was marked by a large number of discoveries and inventions in the field of engineering sciences and technology. In 1902, an engineer from Bremen (Germany) Trigve Larsen made an interesting observation: if metal strips are bent in the form of a trough, then they can be riveted together so that a continuous surface is formed. The technical innovation was patented in 1910, and soon the Tyssen plant began production of these products, named after the German inventor.

What it is?

Sheet piles - Larsen sheet piles are a special section profile with rounded edges - locks that can be connected to each other, forming an almost impenetrable surface. The presence of grooves allows you to connect several elements at once, without requiring the use of welding.

Applications

Today sheet piles are successfully used for:

- fencing of ponds, reservoirs, dams, locks;

- protection against crumbling and collapse of walls of foundation pits, trenches, foundations;

- isolation of places where aggressive substances are stored (for example, landfills and collectors), as well as roads and railways;

- strengthening areas of soil prone to landslides;

- construction of walls in tunnels, underground parking lots, garages;

- equipment for drainage facilities;

- creating soundproof walls (for example, around noisy highways);

- arrangement of drainage channels around roads;

- construction of reservoirs for collecting groundwater;

- as well as in the construction of berths, bridges, dams.

Specifications

The tensile strength characteristics of sheet piles must be at least 1497 MPa. Weight 1 / lm, depending on the type of sheet pile, can vary from 53 to 140 kg. A square meter weighs from 78 to 252 kg. Manufacturers produce sheet piles in various sizes: the length can be from 5 to 22 meters. Price parameters depend on the weight of the pile and range from 58,710 to 64,000 rubles per ton. As a rule, the cost per linear meter is not determined.

A specific characteristic of Larsen sheet piles is turnover - the number of possible dives and notches that one profile can withstand, while maintaining its operational characteristics. This parameter depends on the quality of the source material. In addition, it is important:

- profile length (short turnover is higher);

- the qualifications and respect of the installers;

- used equipment;

- the presence of welding in the joints of the profiles;

- the condition of the soil into which the sheet pile is being introduced.

On average, the number of diving cycles is assumed to be seven, however, depending on the above conditions, this value can fluctuate up or down by up to 50%. At the moment, there is no single state standard regulating the characteristics and technical conditions for the production of Larsen sheet piles. Manufacturers are usually guided by several GOSTs: 4781 - 85, 7566 - 2018, 7565 - 81 and other regulatory documents that determine the composition of the material, conditions for testing products and other parameters.

Species overview

Sheet piles can be divided according to several criteria - the material from which they are made and the shape of the lock.

By material type

According to the type of material used for production, sheet piles are divided into metal and plastic, in some cases they are made of reinforced concrete or wood.

Metal piles

At the moment, metal piles are the most widespread. As a rule, they are made from low-carbon steels of ordinary quality, type St3kp (GOST 380 - 2005). The chemical composition of this material includes: carbon from 0.14 to 0.22%, silicon - less than 0.05%, manganese from 0.3 to 0.6%, nickel and chromium - up to 0.3%, nitrogen and arsenic - no more than 0.008%, copper up to 0.3%, harmful impurities - sulfur up to 0.055%, phosphorus up to 0.04%, the rest is iron.

The mechanical properties of St3kp are as follows: tensile strength: 363 - 460 MPa, yield point: 190 - 233 MPa, relative contraction: 22 - 25%. The temperature regime, which retains the declared operational properties, varies from -40 C to +400 C.

In terms of strength properties, the material fully meets the requirements, in addition, the low carbon content contributes to good weldability. An important parameter is the relatively low cost of such metals.

According to the production technology, steel piles are subdivided into:

- hot and cold rolled;

- welded;

- combined.

Rolling is a change in the shape of a workpiece using rotating shafts of a certain profile. Depending on the temperature regime, there are two main types of this technological process. Hot rolling involves heating the billet above the recrystallization temperature in order to facilitate the plastic deformation process. Cold rolling is carried out at room temperature, as a result of which the surface layer is hardened due to the formation of work hardening - a change in the shape of the metal grain.

Depending on the purpose, there are five main types of rolling mills, one of which - the section one - is intended for the production of sheet pile profiles, as well as other shaped profiles.

The profile shapes that a Larsen tongue can have are very diverse: flat, angular, trough-shaped, I-beams, Z-shaped, S-shaped, combined, reinforced, etc.

The most common is the trough-shaped profile. Flat tongue is used in cases where anchoring is not applicable, as well as when fencing round surfaces. Special corner elements are used to connect the piles. In some cases, mini-dowels are made. The selection of a profile is carried out depending on the tasks and on the basis of the project.

Plastic piles

In recent years, along with steel, Larsen plastic dowels are increasingly used. As a rule, polyvinyl chloride (PVC) is used for their production. The technological process of such profiles is called extrusion. Its essence lies in forcing a soft polymer (compound - "raw" PVC) through holes of a given size and shape (extruder). A necessary condition for this operation is heating to a temperature of 80 - 120C.

Crude PVC composition, which includes:

- coloring components (most often titanium oxide and iron oxide are used to obtain white and brown colors, respectively);

- auxiliary substances that provide lubrication - the possibility of unhindered passage of the mixture between the metal surfaces of the extruder;

- fillers introduced into the composition of the compound in order to correct the physical and mechanical properties;

- plasticizers, with the help of which resistance to negative temperatures and an increase in elasticity are ensured;

Compared to steel sheet piles, plastic products are distinguished by:

- corrosion resistance;

- low weight, due to which the costs of transportation and installation work are reduced;

- low cost of the profile;

- resistance to seasonal temperature changes;

- electrical neutrality;

- attractive appearance that allows you to use the profile in landscape design.

The disadvantages include:

- high coefficient of thermal expansion (there is a risk of destruction of the structure if thermal clearances are not provided);

- lower strength values compared to steel;

- relatively low resistance to ultraviolet radiation.

According to the shape of the castle

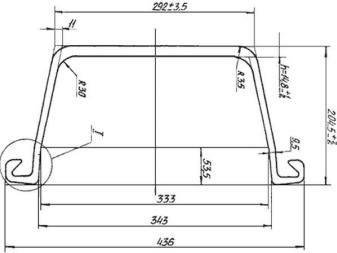

In addition to the profile, tongue-and-groove piles are classified according to the shape of the lock. In addition, there are other piles that do not have locks, as well as modifications that use welding. These profiles can be combined with each other to provide a stronger connection. In the countries of the former USSR, sheet piles of Russian, Ukrainian production, as well as those supplied from European states, have become widespread. Today, three types are most common: L4, L5, L5-UM.

L4

|

Tongue type |

Material grade |

Useful width, mm |

Running meter weight, kg |

Weight per square meter, kg |

Wall strength, kN / m |

Market prevalence |

|

L4 |

St3kp, 16HG * |

405 |

74 |

182,7 |

517 |

high |

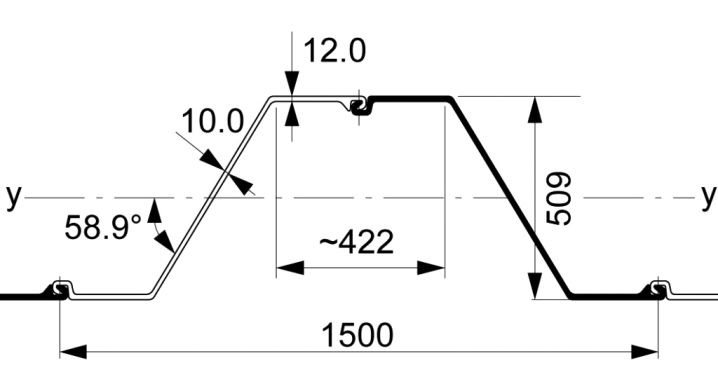

- L5

|

Tongue type |

Material grade |

Useful width, mm |

Running meter weight, kg |

Weight per square meter, kg |

Wall strength, kN / m |

Market prevalence |

|

L5 |

St2kp, 16HG * |

420 |

100 |

216,4 |

696 – 800 |

very high |

- L5-UM

|

Tongue type |

Material grade |

Useful width, mm |

Running meter weight, kg |

Weight per square meter, kg |

Wall strength, kN / m |

Market prevalence |

|

L5-UM |

St3sp |

500 |

113,88 |

227,8 |

835 |

high enough |

* Steel 16HG - low-alloy steel containing about 0.16% carbon, 1% manganese and silicon, the rest is iron and impurities; mechanical and operational properties are close in St3kp.

Diving methods

The construction of a sheet pile fence begins with an assessment of the construction site, in particular, the presence of geological risks. After that, a project is carried out, on the basis of which mathematical calculations are performed using specialized programs. This allows:

- calculate the required pile section;

- determine the required immersion depth;

- make recommendations for taking additional measures (as needed).

For the design of the fence, the soil balance method is usually used, taking into account the loads that act on it inside and outside, since the pressure balance is disturbed during excavation.

When calculating the sheet piles, the Blum-Lomeyer method (graphic-analytical method) is used, taking into account the active and passive pressure of soil and water, the depth of the pit and the vertical size of the sheet piles.

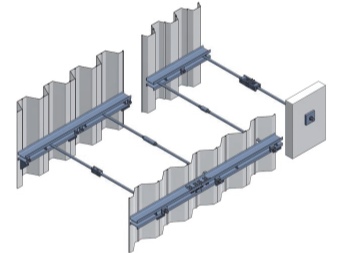

In addition, we necessarily mean the type of sheet pile walls, which can have two types of construction:

- anchor;

- anchorless.

If the anchor type of sheet pile walls is used, the pile turning point should be located at the bottom of the excavation, with the non-anchor type, in the place where the brace for the anchor will be installed.

The value of the pile immersion depth depends on the quality of the soil: in the presence of a silty, sandy, loamy substance, this parameter is taken from 2 meters, for dense soils - from 1 meter. The standard STP 139 - 99 developed by the Gipromoststroy Institute is used as a guiding document.

After the calculation, the immersion technology is described. Pile installation can be done in three ways:

- by indentation;

- shock method;

- using vibration equipment.

The essence of the first method is the introduction of piles into the soil by means of static compression using specialized equipment. This method is the least productive, but recognized as the safest and most gentle (no noise and vibration).

The second method, on the contrary, is very effective, however, there are harmful factors: high vibration and noise background, creating a danger for communications that may be located near the place of work, therefore it is recommended to pre-drill "leader" wells.

Vibration immersion (often in combination with erosion) should be used in places with dense buildings, as well as in the presence of loose soils saturated with water. The essence of the method is to lower the vibrator due to its weight and vibration amplitude. The execution of works on the installation of sheet piles is regulated by the relevant documents. The order of work includes several operations.

- Marking the position of the piles on the ground.

- Installation (attachment) of the vibrator to the pile.

- Fixing the tongue with a cable.

- Placement of the pile in the conductor.

- Lowering the sheet pile into the ground to a predetermined depth.

Transportation of sheet piles can be carried out using any means of appropriate load capacity.

An important condition is the need for their reliable fastening - for this purpose, gaskets are used. Piles can be stored both in warehouses and outdoors.

How to extract?

Dismantling of piles is not an obligatory operation - in some cases they are “buried” in the structure. Nevertheless, the extraction of sheet piles can often bring tangible economic benefits, since in this case they are supposed to be reused.

To carry out the work, a technology based on the use of vibration has been developed. At the same time, the friction forces arising on the lateral surface of the tongue are noticeably reduced. In some cases (on light sandy soils, with short piles), it is possible to excavate the sheet piles only with a crane.

What is Larsen tongue and groove, see the video below.

The comment was sent successfully.