Veneer restoration and repair

What makes old furniture visually? Over time, you can see that the top layer on your favorite Soviet table has moved away from the main surface, dents and chips have appeared, the paint has faded, the varnish has cracked. A completely peeled table surface or swollen areas will clearly hint that the piece of furniture needs to be replaced with a new one. At the same time, the situation is different for everyone - not everyone can afford to buy a new set, perhaps this product is expensive as a memory, or it’s just a pity to throw out a thing that has served for many years. Comfort habits can also play a big role.

Is it possible to repair the surface without replacing the wood? It turns out that it is quite possible to do this. Therefore, consider the options for veneering at home.

How to replace?

First you need to remove the layer that has come off, the unevenness will need to be covered with a putty designed specifically for wood (solid wood, chipboard and MDF surfaces), sand and degrease the surface, let it dry.

Preparatory work before veneering should be done clearly so as not to spoil the result.

If you need to veneer the edge of the furniture, you can get by with a simpler option - purchase a melamine edge. This will greatly facilitate the finishing task. To glue the narrow veneer edge to the edge of the surface, you will need to initially apply and dry several layers of adhesive to ensure maximum adhesion.

But we are considering those options when the area of the damaged surface is quite extensive. Indeed, when pasting large surfaces, you will have to make more effort. After preparing the wood, you will need to make measurements, purchase materials.

For restoration we need:

- veneer;

- adhesive composition (PVA is suitable for thermal gluing) in the absence of an adhesive base under the film;

- thermal glue iron (you can use a lapping hammer, if you have one);

- brush and roller;

- sandpaper;

- plywood knife (or power saw);

- small block.

For gluing on chipboard, the surface should be prepared initially - this is easy to do by priming it with the same glue.

PVA glue can be used for gluing. It can be any wood glue - their compositions are quite similar. Rubber based glue will also give good results. Epoxy and polyurethane compounds can also glue the veneer. Urea resin is also suitable.

Veneer is often sold as a roll, so it must be flattened first. To do this, the material must be lightly sprinkled with water from a sprayer or soaked with a damp sponge, then additionally pressed down with a sheet of drywall - this will speed up the straightening process.

Cutting veneers should be done with a margin of 3-5 cm around the perimeter - this will help to avoid empty cuts at the edges when gluing obliquely. A plywood knife will do the job perfectly. On the finished product, the excess is also cut off and the cut is lightly skinned.

Using scissors is not recommended - most likely, this will lead to cracks in the canvas.

There are several ways of gluing veneer:

- cold contact method;

- hot gluing;

- gluing by pressing without heating.

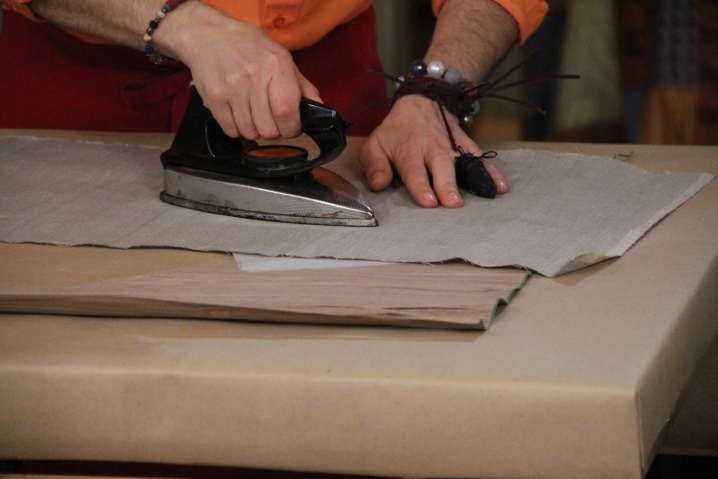

With the hot method, the process of gluing surfaces occurs when the glue is heated; an iron is usually used for this at home.Since the surface of the wood layer will heat up, it is convenient to use a wooden block to rub the veneer itself against the wood and "blow off air" over the edge, so as not to burn your hands.

The veneer layer is covered with glue, they will also need to soak the wooden surface, and then dry each one.

Veneer application should be done carefully, checking the edges to avoid empty spaces. In doing so, lightly press down on the veneer layer to avoid air bubbles between the surfaces.

If there are any, it will be necessary to drive them out immediately, for this it is better to use a bar, and not your palms.

After applying and removing air voids, they begin to iron the surface with an iron. It is better to separate the iron from the veneer surface with a sheet of clean white paper or clean thin cotton cloth. Movements should be clear, fast and with the use of force. It is not worth heating the surface with an iron for a long time, so as not to spoil the glue. Heating with an iron should take place from the center of the sheet to the edges.

After ironing the veneer with an iron, allow the surface to cool. When cooling down, you can cover or press down the surface to be veneered with an even flat weight.

The cold contact method will require more skill - it is more difficult for a beginner than hot gluing.

Contact adhesive dries quickly, which means that it will take much less time to fix irregularities. The glue is also applied to two surfaces. After the glue has been applied, the surfaces should be dried. When gluing large areas, a barrier between the work surfaces can be used to avoid premature adhesion. Use plastic or thick sticks.

Initially, you will need to fix one edge of the surfaces to be glued, rub them to each other with a bar, only then gradually move the barrier, adding a new area for gluing. In this case, smoothing occurs without a bar from the center to the edges. After joining the surfaces to each other, the rubbing process begins over the entire surface. If at the same time gluing goes with joints, then it is with them that you should start. This method is not recommended for large surfaces.

The cold glue pressing method will require clamping clamps or strong clamps over the entire surface, which are removed when the glue dries.

Veneer repair

Sometimes it happens that the edge of a veneered table that has already served for a long time is swollen, a small piece of veneer leaves it, and this part needs to be updated, or scratches need to be removed. How can such a defect be repaired?

Restoration is simple - do it yourself. The detached part can be glued. In this case, there is no need to repair the veneer from the entire cabinet door or table surface. You can restore a separate area. This place needs to be sealed - the surface is simply greased with glue and rubbed with a soft, clean cloth.

If the surface contains furniture fittings, then it should initially be removed from the surface to be restored, and the surface should be sanded.

When a large area of veneer is removed, the repair process takes place in the same order, but in the future it will be supplemented with staining and varnishing.

Recommendations

Before starting work, it is better to cover the carpet or carpet with foil, if any.

Only fresh glue is required for such a purpose; you should not take one whose shelf life will come out in a couple of months.

Sanding begins with coarse sandpaper, and ends with "zero".

When pasting ornate surfaces, it is better to use not PVA, but wood glue. For such purposes, you can use the products of Kleiberit or Duditerm, and this will already be a more professional and expensive approach. And also Contact Kraft and Kraft Transparent adhesives will perfectly cope with this task.

On such adhesives, they usually write the conditions that are most suitable for this model - whether it is air humidity or the presence of running water on the surface, room temperature, and more.

When gluing corners and edges, it will be convenient to use a soldering iron.

You should not heat the iron, as this will lead to the glue sticking - it would be better to use an average temperature. You should also not steam the veneer.

After heating is complete, you can tap the surface - a ringing sound will give out those places that need to be ironed additionally.

When hot gluing, the veneer should not dry out too quickly, this will slightly adjust the process. To avoid the glue drying out too quickly, you will need to slightly moisten the veneer with water.

If, during hot gluing, air bubbles appear that cannot be released, then a small incision or puncture of the surface can be made.

And a few more tips from experts.

- For hot gluing, a thick glue is needed, while for other methods, a more liquid one is suitable.

- If there are burn marks, they can be removed with a sharp knife.

- Grinding a new surface is required according to the location of the wood fibers.

- After drying, you will need to apply a layer of varnish or cover the surface with a special film. This will help prevent moisture absorption.

- The color of the veneer itself may differ in shade, but most often the “wood species” should be the same.

- The process of cutting the sheet itself with a knife should occur across the fibers themselves. This approach minimizes the possibility of damage to the sheet.

- Gummed tape will help fix the veneer at the joints before gluing.

- After gluing and completely drying, you can paint the veneer in any desired color. To do this, use any paint on wood.

All these techniques are well suited to restore your favorite furniture from bulges, chips and cracks at home without expensive investments and transportation to specialists. Restoration can be done at home yourself with the help of available tools.

The main thing is to correctly compare the degree of damage and the required materials, to decide on the choice of the method itself according to the existing skills in construction and repair.

For information on how to repair veneer, see the next video.

The comment was sent successfully.