Finishing putty: subtleties of choice and use

Finishing putty is a dry white mixture of a fine fraction or a ready-made solution based on it. Serves as the basis for decorative finishing works such as painting, wallpapering and others. "Superfinishing" putty is designed to level small scratches and chips formed in the process of applying finishing with working tools. Before buying, you must familiarize yourself with the main criteria for choosing this building material.

Peculiarities

The finishing putty may itself be the final decorative finish.

Its immediate purpose is:

- final leveling of the surface;

- elimination of minor flaws in the wall or ceiling;

- strengthening the protective properties of the treated surface: water resistance, frost and heat resistance, resistance to mechanical stress and vibration, and the like;

- imparting the necessary performance properties to the base layer, for example, plasticity, in order to avoid the formation of cracks.

- improving the quality of the working surface after the previous coarser processing and its preparation for further finishing;

- giving the surface an aesthetic appearance, uniform color.

Quality standards

To understand what to expect from putty mixtures, you first need to find out what requirements are put forward for them from a professional point of view.

For a high-quality finishing putty, the following features are characteristic:

- when mixing dry mixtures, there should be no lumps in the solution;

- high adhesion - strong bond with the surface material at the molecular level;

- finally levels the surface to a flat plane;

- easy to apply;

- the solution does not slide down the wall;

- after the solution hardens, no cracks form;

- easy to grind;

- painted in a uniform white color over the entire area of application.

How is it different from the usual one?

When decorating walls and ceilings, various types of putty mixtures and solutions are used: starting, finishing and universal, as a replacement for the previous two.

The finishing putty has a number of properties that radically distinguish it from the starting one, including:

- consists of a fine-grained powder with a maximum of 0.7 mm in diameter, and the starting one is of a coarse fraction;

- intended for the final leveling of the prepared surface, the starting mixture - for significant correction of the plane and filling large holes;

- the hardened layer is relatively smooth, the starting layer is rough;

- must be plastic, cracks on the finishing layer are unacceptable;

- easier to grind than starting composition on the same basis;

- has an aesthetic uniform color over the entire plane.

It can be noted that the difference between these mixtures is quite significant.

Views

Finishing putties are divided according to two main criteria: according to the state of readiness and composition. They can also be divided according to the area of application into those that are used for external and those that are used for internal work.

Finish putties, according to the state of readiness, are divided into the following two types:

- Dry mixes. For the use of such filler materials, the accumulated filler skills are required, in particular, the skill of mixing the solution. If mixed incorrectly, the mixture will contain lumps, which will necessarily appear on the hardened layer. In skilled hands, the material gives a good surface, it is often used as a base for wallpapering.

In unmixed form, it can be stored for a long time without loss of quality. All dry mixes are cheaper than mixed analogues.

- Diluted solution. It is realized in a ready-to-use form. Simple and easy to use, does not require additional skills to use. Gives a flat and smooth surface without lumps. It is used to create a base surface for painting, decorative finishing works and other purposes.

Divorced species are popular with DIY repair enthusiasts. In terms of price, such mixtures are more expensive, including due to additional additives, some brands have a long shelf life.

Putty "Multifinish" is made from substances of various properties. Each type has unique characteristics, strengths and weaknesses, both in terms of performance and financial terms, as well as in application features, types of suitable surfaces and other aspects.

Depending on the components included in the composition, the finishing putty is of the following types:

- plaster;

- cement-based;

- polymer: acrylic and latex;

- water-dispersive.

Gypsum

A common type of finishing materials, widely used in the processing of cement surfaces and drywall. Ease of use has made gypsum plaster the main choice for beginners and people who do not have serious experience in filler.

The characteristic features are:

- relative ease of mixing dry mixtures;

- fits well on the surface of the wall;

- short drying time of the layer;

- lack of an unpleasant building smell;

- minimal shrinkage;

- no cracks form on the solidified layer;

- the resulting surface is characterized by good smoothness and evenness;

- easy to grind;

- one of the best bases for coloring;

- the composition contains only natural ingredients, as a result of which microparticles do not provoke allergic reactions;

- low moisture resistance makes the use of gypsum putty ineffective in rooms such as bathrooms or kitchens;

- non-flammable;

- enhances the thermal insulation properties of the surface;

- dry can be stored for long periods without deterioration;

- fragile, easily deformed from the effects of vibration and mechanical stress, it is inappropriate to use in places of increased human activity, where contact with walls is a regular occurrence;

- relatively inexpensive.

Cement based

The main part of such a mixture is cement; sand and water are used for mixing. It stands out for its low price and is the main working option when it is necessary to perform large amounts of putty work.

Distinctive features of cement putties are:

- exactingness to the sand and water used, the sand should be coarse (from 1.5 to 2.5 millimeters), the added water should have a temperature of about +20 degrees Celsius, otherwise cracks on the dried layer are guaranteed;

- the rate of solidification of the mixed solution ranges from 5 to 24 hours, depending on the specific manufacturer;

- the cement mixture shrinks, reapplication is common practice;

- cracks may appear even if the technical process is followed;

- high moisture resistance;

- good frost resistance;

- high strength;

- relatively difficult to grind;

- not used on wooden surfaces;

- the standard cement putty, when hardened, becomes an unremarkable gray color, if it is planned to glue thin wallpaper, then varieties with coloring additives of white and "super white" color are used. Dyes increase the price of the mixture from 240 to 660 rubles per 20 kg.

Polymer

A heterogeneous group of filler materials based on polymer substances, the most common are latex and acrylic. They have a number of similar properties, however, they also have different properties.

Polymer putties are characterized by the following qualities:

- a good smooth and even surface of the hardened layer, regardless of the severity of the surface flaws;

- are produced in the form of dry mixtures and ready-made diluted solutions; mixed putties, due to their ease of use and ease of obtaining a good result, are in great demand among inexperienced builders and people doing repairs with their own hands;

- excellent base surface for decorative finishing works;

- improves the soundproofing qualities of the surface;

- high vapor permeability ensures "breathing" of the surface, as a result of which the room does not damp, and the air circulates normally;

- good moisture resistance determines the choice of polymer putty for finishing wet rooms, for example, bathrooms, steam rooms, kitchens, etc.;

- the composition is biologically inert, mold does not grow on it, and fungi do not multiply, which is especially typical for a bathroom;

- does not have a characteristic building smell;

- for the price - this is a premium class;

- acrylic-based mixtures can be used for both outdoor and indoor work, have a strong resistance to weather conditions: snow, low and high temperatures, rain, a strong structure effectively protects against mechanical damage;

- putties, which contain latex, are used exclusively for indoor work due to their weak resistance to low temperatures, do not shrink, are highly plastic and at the same time resistant to mechanical stress, durable.

Water-dispersive

Such putty mixtures are sold as ready-to-use water-dispersion compositions based on acrylic.

They are widespread due to the large number of positive qualities, including:

- fit well on various types of coatings: concrete, brick, wood, drywall and others;

- strong adhesion - good "adhesion" to the surface material;

- have a slight shrinkage of about 2%;

- good moisture resistance, such compositions are often used for finishing work in bathrooms and kitchens;

- not afraid of temperature changes;

- it is possible to improve the mixture by adding synthetic resins that improve performance: they accelerate drying, increase plasticity and strength;

- fit well on the surface;

- amenable to grinding;

- financially inexpensive;

- the hardened composition can be thinned with a small amount of water;

- do not exude strong odors;

- fireproof.

Which is better?

In order to choose the optimal type of finishing putty, first of all, you need to determine for what purpose it is chosen.

Possible selection criteria are:

- Place of work. Putty for outdoor use is very different from indoor, especially in terms of resistance to weathering.

- The surface to be putty. Some types of putty fit well on various types of surfaces, for example, water-dispersion, others have limitations, for example, cement putty is not used on wood.

- Required qualities such as plasticity, adhesion or sandability. In many ways, their list is determined by the plan for further finishing work.

- Protective properties such as moisture resistance, resistance to temperature extremes, resistance to mechanical stress, acid resistance and others. Finishing putties with the addition of synthetic additives, which have pronounced protective qualities, belong to the group of "special" putties. They are used for finishing in premises with a specific aggressive environment.

- For what further finishing work is the finishing putty selected. If it becomes the front surface of the wall, the so-called superfinish putty will help to give an excellent appearance.

- Shelf life, especially for ready-made solutions without special additives, such mixtures are strictly limited in time of use.Dry mixes generally have long shelf life.

- Budget. The best qualities are not always in proportion to the price. So, slightly inferior polymer water-dispersion putty is much cheaper, but it is not biologically inert, which can become a key point when choosing.

Possible applications for different types of fillers under different conditions:

- For facades, large and unheated rooms, rooms with high humidity such as bathrooms, showers, steam rooms, a cement-based putty will be a good solution, especially if you take into account its low price.

- For residential premises with low humidity, it is advisable to use a plaster putty, it will be a good base for painting, gluing thin wallpaper. It can be used for decorative finishing work, it will well hide flaws from previous processing.

- If it is necessary to obtain an ideal surface for a decorative finish, a polymer putty will be suitable. If the base surface is of high quality, then its consumption will be negligible.

- Depending on the budget, there are 2 good options for the bathroom. The best is a polymer putty, although cement and it is not inferior to it in moisture resistance, but mold does not grow on the polymer composition and fungus does not multiply, which is not to say about cement that absorbs water well. An alternative with a more modest price is a water-dispersion mixture, which also resists moisture well.

Inappropriate uses are:

- The use of cement compositions as a base for painting or thin wallpaper, the texture of this putty is rough and difficult to grind, when opened with paint, flaws will become obvious, over time the cement cracks and loses its normal appearance, from under the wallpaper (not thick) it will shine through with dark spots.

- The use of gypsum putty in a bathroom or kitchen, despite the pleasant aesthetic appearance, such a surface will quickly become unusable.

- Using polymer mixes to cover large areas or patching up a failed basecoat can add up to a serious amount of money.

An important subtlety is the choice of finishing building materials from one manufacturer. The interaction between their components is guaranteed by testing and laboratory research. If a certain brand is used for the plaster and the base layer, for example, Knauf, then it is better to take the finishing putty from their production.

Consumption

The consumption of putty per 1 m2 depends on many different factors: on the thickness of the applied layer, on a specific brand, on the type of work performed, etc.

First of all, the consumption of the mixture is determined by the type of work for which the finishing putty is used and it is something like this:

- 0.5 kg of mixture per 1 sq. m. is consumed when firmly gluing wooden elements to a layer of finishing plaster.

- 0.9 kg per 1 sq. m. to eliminate gaps between two plasterboard sheets.

- 1.1 kg per 1 sq. m. when leveling walls for painting or gluing wallpaper.

- 1.2 kg per 1 sq. m. is used for leveling internal walls.

- 1.7 kg per 1 sq. m. when finishing the front walls.

For an example of the consumption of finishing putty, consider products from several specific manufacturers:

- Ceresit 225 CT consumption 1.8 kg per 1 sq. m. A cement-based mixture, applied over the base layer as the final part of the filling. The resulting surface is characterized by evenness, smoothness and aesthetic snow-white color. Also contains additives that enhance frost resistance, the composition includes reinforcing fibers, waterproof.

- Vetonit VH the consumption of the mixture is 1.2 kg per 1 sq. m. Consists of limestone and cement with a white coloring additive. Spray applied, moisture resistant, used both for indoor and outdoor work.

Usage Tips

Perhaps the first thing to remember is the conditions in which it is better to carry out the finishing putty.The humidity in the room should be no more than 60%, at an air temperature in the range of 15 to 30 degrees Celsius. Without these conditions, it will become difficult to work with the solution, even if all other instructions are followed.

For a high-quality finishing putty, you need to adhere to a proven application technique, consisting of three main stages:

- priming the hardened base layer;

- putting putty on the wall;

- grinding the hardened layer.

Before starting work, it is necessary to clean the surface from dust, dirt and other foreign elements. This can be done with a damp cloth, solvent, degreaser and other means.

Priming is used to enhance adhesion and remove moisture from the coating. This way, the finishing putty will work better and stay flat after drying. For this purpose, for example, an acrylic primer can be used, which is applied to the wall with a roller just before the finishing putty.

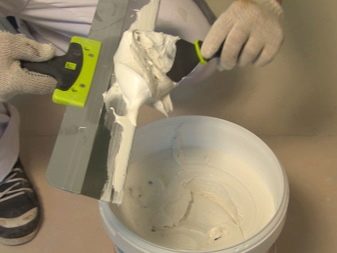

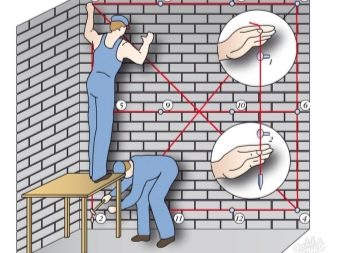

To apply the mixture to the surface, the following tools are needed: spatulas, narrow for a set of mortar and its distribution, wide for stretching the mixture along a plane and angular for processing the joints of walls and ceilings, a level, a plumb line, a mixer. In order for the resulting solution to comply with the standard, the proportions indicated on the label should be strictly observed.

Before mixing the entire volume, you can conduct a test dilution of a small amount of the dry mixture, determining the proportion to obtain the desired consistency. To thoroughly knead the solution, you need a mixer or drill with a stirring attachment. It will be difficult to manually bring the mixture to full homogeneity. The mixture from the bucket is applied to a wide spatula using a narrow (about 10 cm) rubber spatula.

It is smeared on the wall with a metal spatula, on the surface of which the mixture is distributed. With gentle movements, attaching the tool to the surface, first the spatula is carried along the vertical axis, and then along the horizontal, carefully stretching the mixture over the entire plane. The edge of the finishing tool must be in perfect condition, any defect (dirt, burr, rust) will spoil the uniformity of the surface with furrows.

The last step is grinding. It can be carried out both dry and wet using a damp sponge or sandpaper or abrasive paper. A directional beam of light is used to check the resulting surface, preferably from a flashlight. Sent to a plane at various angles to detect shadows, any of which indicates roughness. The problem area is re-grinded.

The filling process consists of many small nuances, here are some of them:

- There is no single standard for the applied volume of the finishing filler, it is determined after evaluating the base coat.

- Most finishing putties are applied in a layer no thicker than 2 millimeters, otherwise cracks and peeling of the mixture are likely after drying.

- While rubbing the mixture on the wall, it is better to hold the spatula at an angle of 20 degrees.

- It is worth regularly cleaning the spatula with a damp sponge to remove adhering pieces of the mixture, otherwise, accumulating, they will leave furrows.

- To control the evenness of the surface, a level and a plumb line are applied.

- The curing speed of the finishing putty ranges from 10 to 15 minutes.

- Before sanding, the layer is allowed to dry for about 12 hours (the time varies depending on the composition of the putty).

- They grind mixtures based on polymers and gypsum, grinding cement is useless.

- If painting is planned, sanding should be especially careful and scrupulous, the paint will reveal all defects. If you plan to glue wallpaper, it is enough to moderately treat the surface.

- It is better to grind the finishing putty with your hands, measured in circular movements until the traces from the spatula completely disappear.

- Optimal emery grain size is in the range from 220 to 280Р.

- Overlapping the surface with a spatula eliminates transitions and unevenness from excess mixture.

Depending on the further finishing work, the final filling is carried out with the application of a different number of layers of the mixture:

- for gluing thick wallpaper on non-woven or vinyl, a base of one layer of putty is suitable, if thin ones are glued, then two or more;

- for the base surface for painting with paints on an acrylic and polymer base, a base of two or three layers is created;

- when painting: the lighter the dye, the more snow-white the finishing putty should be applied, applied in a thin layer; when using light colors, a "superfinishing" polymer putty is used.

In the process of filling the surface for painting, it is worth adhering to the following rules:

- the thickness of the applied layer should not exceed 2-3 millimeters, otherwise delamination is possible;

- a new layer is not applied immediately, but only on a completely dry previous one;

- the total thickness of the layer applied for painting depends on the color of the future coating: the lighter the dye, the thicker the layer;

- you need to start sanding after the final drying of the final layer, this moment occurs in the period from 6 to 48 hours after application;

- at the end of sanding, before further finishing, dust must be removed from the surface or this will affect the quality of adhesion of materials;

- the putty surface must be primed before painting.

Depending on the type of finishing putty in composition, the hardening time of the mixture differs:

- the cement slurry begins to harden 5 hours after being applied to the wall;

- gypsum putty sets after 1.5 hours, you should not dilute it in large volumes;

- polymer compositions without additives that accelerate this process harden after 24 hours.

It is better to choose a mixture that dries for a short time. This will speed up your repairs a bit.

Manufacturers

Finishing putty is represented today by a large number of brands from various manufacturers. We present to your attention a rating of the most famous and popular manufacturers.

Quality mixtures include the following products:

Knauf HP Finish

Gypsum putty from a German manufacturer, sold as a dry mix. The composition contains additives that improve the smoothness and facilitate the leveling of the layer. The solution fits well on various types of surfaces: concrete, cement, drywall.

Maximum application thickness is no more than 3 millimeters. Used for filling in dry rooms, moisture resistance is low. Knauf HP Finish Super Pack 20 kg.

Other features:

- final hardening of the layer after 15-24 hours;

- the diluted mixture begins to set after 2 hours;

- approximate consumption with a layer of 1 millimeter thick - 0.9 kg per 1 sq. m.

"Eunice Premium"

Dry polymer mixture for interior use. It is used for work on such types of surfaces as concrete, cement, gypsum, plasterboard and gypsum fiber. Creates a smooth white surface with a "mirror" effect.

Excellent base for painting and decorative finishes. The maximum applied layer thickness should not exceed 3 millimeters.

Also, this mixture is characterized by:

- fast complete drying: from 3 to 6 hours;

- diluted solution is suitable for about 16 hours;

- with a layer thickness of 1 millimeter, the consumption is from 1.1 to 1.5 kg per 1 sq. m.

"Vetonit LR +"

Dry polymer mixture, used for work on concrete, plasterboard and gypsum fiber. Forms a high-quality white coating, well suited for painting. The working layer thickness is from 1 to 5 millimeters.

Also putty "Vetonit LR +" is characterized by the following qualities:

- complete hardening occurs within 24 to 48 hours;

- after dilution, it retains working properties for about 24 hours;

- with a layer thickness of 1 millimeter, 1.2 kg is consumed per 1 sq. m.

Sheetrock super finish

Diluted solution based on polymer vinyl. It is used for most surfaces, when cured it gives an excellent smooth surface, easy to apply. The coating is durable and very moisture resistant.

Also, this mixture has the following parameters:

- the solution sets after 5 hours;

- consumed at a thickness of 1 millimeter, 0.7 kg per 1 sq. m.

Among the popular manufacturers, one can also highlight the companies "Hercules", "Bolars", "Osnovit".

Reviews

As for the reviews about the finishing putty, it all depends on the selected brand of a particular manufacturer:

- Weber Vetonit LR +. To the pluses of this product, buyers consider the ease of use and the evenness of the finish layer. The putty mixes quickly, easily adheres to the surface, dries quickly. However, some buyers talk about the high fragility of the material: it crumbles during grinding. If you do not follow the instructions for use and dilute the product too much, then it can shrink, and the coating will begin to crack.

- Knauf HP Finish. The material is easy to use, easy to mix, quickly sets, there is no unpleasant odor, and is well polished. This putty is perfect for treating not only walls, but also floors. There are practically no drawbacks to this product.

- Sheetrock Super Finish. The advantages of this product include excellent frost resistance, high strength, plasticity, ease of application. The only drawback, according to buyers, is the rather high cost of the material.

For information on how to choose a finishing putty, see the next video.

I am delighted with the "Polyfilla" putty! Nice to work with.

The comment was sent successfully.