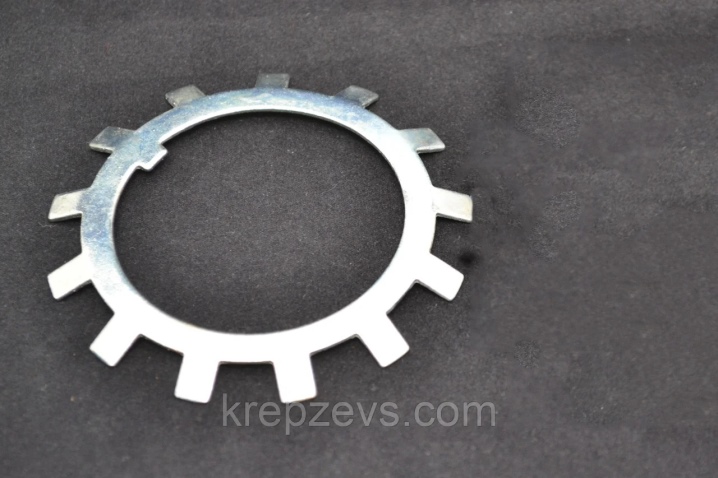

All about multi-foot lock washers

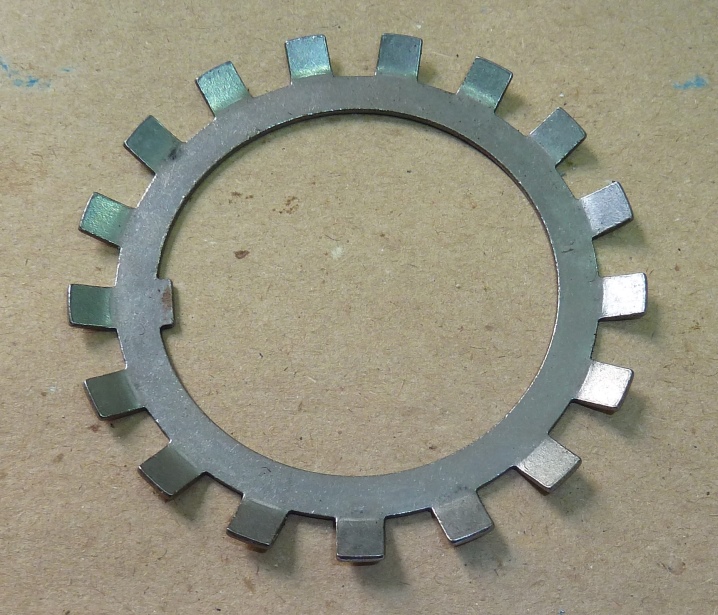

A fastener such as a multi-footed lock washer is a product needed to improve the reliability of connections by means of a threaded fastener. It prevents loosening of the fixing due to loosening of the nuts, but it can also prevent other problems and malfunctions during the assembly of various structures.

Description and purpose

With long-term operation of many technical devices, the main criterion for durability is the strength and reliability of the connection of different parts of the structures. Correctly chosen locking multi-foot washer avoids spontaneous loosening of fasteners, and so-called feet help it in this.

It is the legs that hold the fixation in a constant position, despite vibrations and any mechanical stress.

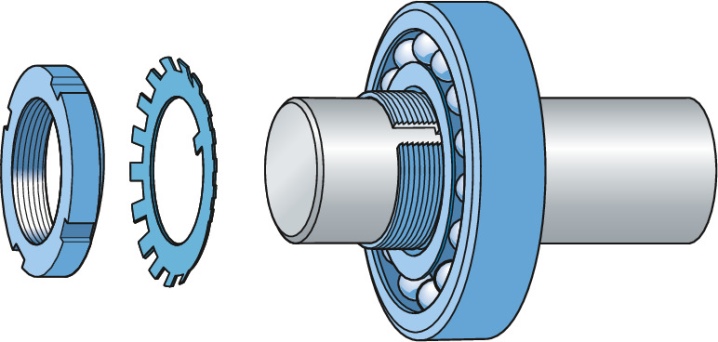

When using slotted nuts on the shafts, these devices completely save the structural unit from destruction. In the grooved groove, the lock washer is fastened with a protrusion on the inside, in turn, this makes axial rotation impossible, while maintaining the normal, unobstructed movement of the fastener in the direction of length. 6 special lugs, tilted at 25 degrees, exclude unscrewing, but the part is effective only in relation to slotted types of nuts.

Therefore, the latching device with an inner tab has the following characteristics:

- the presence of external and internal protrusions;

- mainly the fastener is used for nuts of a certain size - with a diameter of 10-130 mm;

- the location of the legs along the outer diameter can be different, sometimes they are made to order according to the presented drawings, which is due to the specifics of the design for which the fasteners are used;

- since the legs of the element can be bent many times during operation, the main material for their production is high quality plastic stainless steel;

- depending on the diameter of the thread of the spline parts, lock washers are made of thin metal sheets 0.8-2 mm thick, in addition, the surface of the washers is covered with a protective anti-corrosion layer.

Meanwhile, unlike other fasteners, lock washers with lugs are used a maximum of 2 times, and their reuse is not possible, since even with high steel strength, the number of bends is limited.

The main area of application of the part is all kinds of structures and structures of industrial importance (any mechanisms that are subjected to loads on the rotation axis during operation, on the shafts of centrifugal, vane pumps, gearboxes that change the power of cars and production equipment). But in everyday life, the device also found its use - they are often replaced by ordinary flat washers with a hole inside. True, then it is required to select the desired type of nut for engaging the legs.

Requirements

The lock washers with internal lugs, necessary for locking the slotted nuts, must comply with the requirements and standards of GOST, in particular, applicable to products of accuracy class A.

Technical requirements for these parts:

- the absence of any marriage, defects and damage - cracks, tears, burrs, sharp edges, shells;

- absence of traces of corrosion, rust;

- the domestic standard requires 6 legs at an angle of 25 degrees;

- the material of the product must be durable and at the same time plastic - when bending the legs, cracks should not form on them, therefore, different metals are taken as raw materials for the manufacture, but mainly brass, stainless steel grades A4, A2, carbon steel;

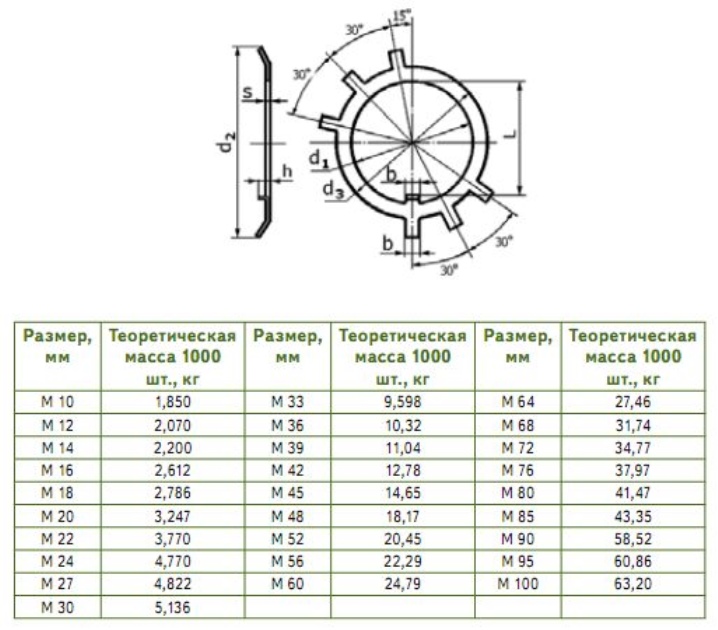

- a certain mass is provided for metal products;

- washers can be covered with a protective layer made by zinc, chromium or oxidation, but the absence of an anti-corrosion coating is also permissible;

- each part must be made in accordance with drawings and dimension tables, taking into account the type of washer and the thread diameter of the slotted nuts.

However, some corrections are allowed - corner tolerances, production of parts with different thicknesses, in addition to that indicated in the table of standards.

The bending of the legs at an angle is not always used, some devices are made without this feature.

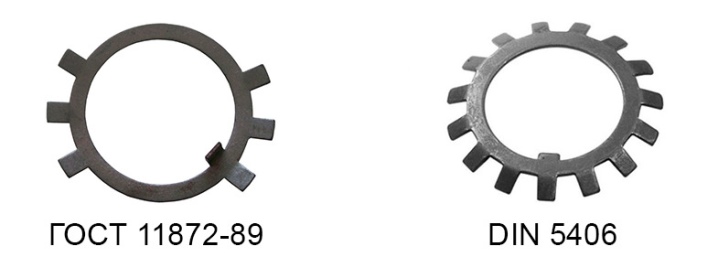

I must say that in our country, multi-footed washers are used, oriented not only to the Russian GOST. Often, parts made in accordance with DIN 5406 are used. But these standards should not be considered completely identical, especially since DIN products often have a larger number of internal protrusions and other differences.

What are they?

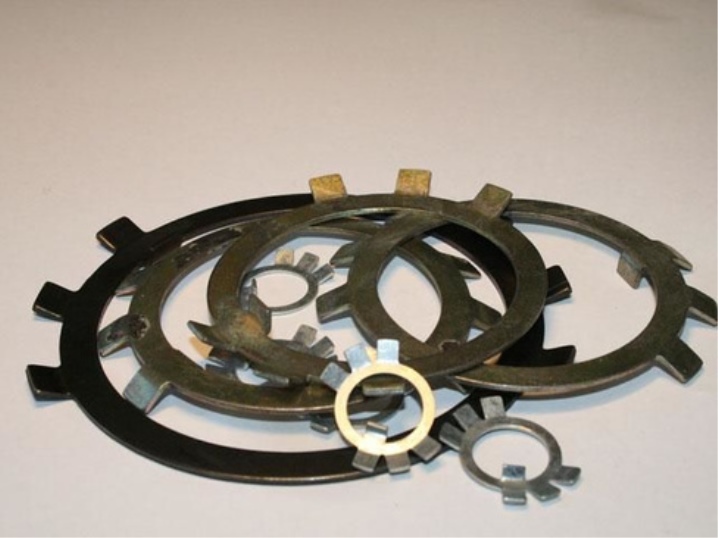

These products are initially produced in two types - light and normal, which differ only in the area of use. Besides, multi-footed washers are divided into several types, also made in accordance with the requirements of GOST:

- reduced size retaining parts;

- multi-footed devices with a toe;

- washers that have evenly grouped legs on opposite parts of the device and are distributed over the entire outer surface, not counting the obligatory inner protrusion.

But that's not all - washers are divided into classes of accuracy and strength, and if necessary, you can choose high-strength products with improved quality and performance characteristics.

Custom made fixtures may differ in material - they are made of titanium, aluminum, copper alloys. As a protection, parts are sometimes coated with solutions of acids, phosphates, cadmium, special oils that increase their wear resistance and service life.

But the most popular, thanks to the guaranteed strong fastening and durability, is the lock washer GOST 11872 89, which is widely used in industry, construction and in everyday life.

What a multi-footed washer looks like, see the video below.

The comment was sent successfully.