Overview and Annealing Copper Washers

The review and annealing of copper washers is a very important topic in the modern technical field. An overview of the sets of sealing washers 10x14x1 mm and other sizes is of great importance. It is very useful to know how to anneal them, as well as what are the basic requirements for the existing GOST.

Description and purpose

The use of various sealing elements is practiced to improve the reliability and stability of screw connections. The choice of material for the washer is determined by what impacts the connection will experience. A copper washer is best suited where there are elevated temperatures and pressures in constant mode or intermittently. Therefore, it is widely used in the engineering industry when assembling mechanisms designed for high pressure. First of all, we are talking about fuel and hydraulic equipment.

The attractiveness of copper washers for a backing on a chainsaw and for a car drain plug is also associated with:

- high chemical resistance of their material in an aggressive environment;

- excellent corrosion resistance;

- preservation of sealing functions under the action of elevated temperatures, as well as with significant fluctuations in the thermal regime;

- vibration resistance;

- strength and stability of basic properties under significant pressure.

Such fasteners can also be used in automotive mechanisms, all parts of which are constantly heated, while still being moistened. This high level of responsibility means that these washers meet very demanding requirements. Compliance with the GOST specified for a specific type of product is of key importance. Compliance information can be found on the original packaging of the kit and on the accompanying quality certificate. The achievement of the required properties depends primarily on the characteristics of the feedstock.

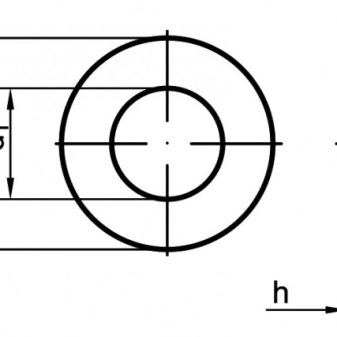

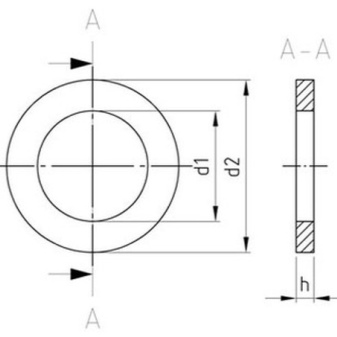

The way the washers look is clearly described in GOST 18123-82. According to this standard, there should be no deviations from the smooth shape on the surface. No burrs or cracks are allowed. Washers with signs of corrosion or with metal drips also do not comply with the standards. Roughness of more than 3.2 microns also makes it possible not to accept the product.

The control process implies, first of all, a visual check. If necessary, an accurate study is carried out through a magnifying glass. Roughness is assessed by indicator standards in accordance with GOST 9378-75 or using specialized measuring devices.

Sometimes the copper washer is coated with a special powder layer to provide additional corrosion resistance. This coating is regulated by GOST 9.302-79.

Features of production

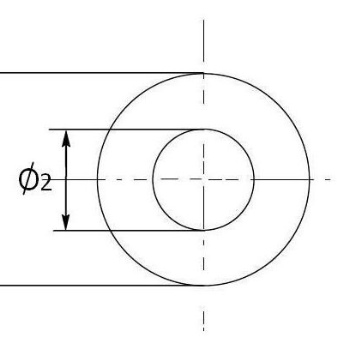

Structurally, sets of copper washers can represent collections of round, sometimes rectangular disks. They are clearly distinguished by their accuracy categories. Standard Accuracy Level - B, Increased Accuracy Level - A. The technology currently being used involves the production of copper washers by cutting or extrusion from metal. The initial elements can be either sheets or plates.

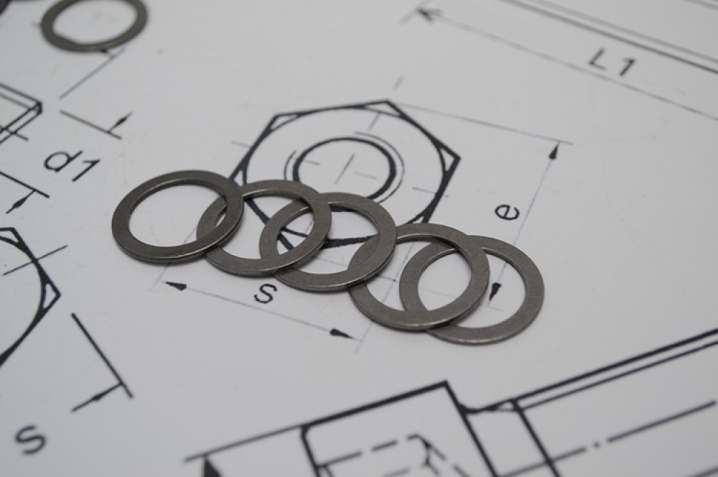

The sealing product must be annealed and then clarified. It cannot have scratches and dents. There should also be no nicks that impede the operation of the washer. The role of annealing is to increase the plasticity of the metal, due to which the deformation of the part with a temperature drop is excluded.

Copper grades M1, M2, M3 are most often used for the production of washers. Among them, the M3 is the best choice. True, the metal can be replaced depending on the nuances of future operation.

In some cases, more exotic grades of copper are used, containing small amounts of oxygen and phosphorus.

Annealing is carried out directly in production, but if the product is stored for a long time, you will have to repeat the procedure.

Material grades

The official marking of the copper washer always indicates the presence of powder coatings. P29 class products are galvanized and passivated. P34 mark means that the product is only passivated. In cases where the standard provides for more than one accuracy class, its designations are placed at the very beginning of the brand. The composition of the marking includes:

- type of execution;

- section of the thread;

- part thickness;

- chemical brand;

- conditional index;

- the thickness of the coating used;

- applied standard.

There are such basic standards:

- GOST 10450-78 (small products)

- GOST 6958-78 (enlarged washers)

- GOST 11371 (flat structures)

- GOST 19752-84 (flat gaskets made of metal for sealing)

- DIN 7603 A (sealing copper rings).

The copper-aluminum washer has a special brand - SHAM. There are differences in diameter. Other brands:

- DIN 125 (basic)

- DIN 433 (narrow, for lining)

- DIN 7349 (for spring pins)

- DIN 988 (support, for adjustment)

- WIDE (body type).

How to properly anneal

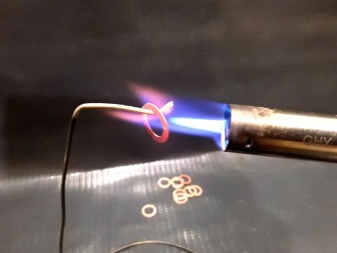

It is worth firing copper washers under the nozzles if only to relieve internal stresses that inevitably appear during material processing in production. But it is very important to follow this procedure clearly. The process is carried out when heated to 700 degrees. Then the parts are smoothly cooled in a natural way at normal temperature until they cool down to +25 degrees Celsius.

Heat treatment is carried out using a welding torch. The flame is kindled in it using oxygen and acetylene supplied from different cylinders. Another important nuance - gloves and glasses are required. There should be a fire extinguisher near the place of work. Having connected the hoses to the cylinders, it is necessary to open the acetylene valve on the burner by 50%. After firing up the gas, wait until an orange-red flame appears.

Thereafter, the oxygen valve is opened until a blue flame appears. At this moment, the washers are burned. The fire is directed at the puck and directed along the surface, achieving a cherry red glow. Thereafter, immediately close both gas valves. Then, as already mentioned, you will have to leave the products to cool.

Dimensions (edit)

The dimensions of copper washers vary greatly according to the applicable manufacturing standard and the area of use. In domestic practice, there are the following basic dimensions:

- sealing washers for KAMAZ 6x12x1 (1.5), 8x12x1.0;

- sealing for oil pipes of KAMAZ and MAZ 8x12x1.5, 9x15x0.7;

- for KAMAZ injectors 9.7x17.5x1.5;

- for fuel lines 10x16x1.0 (1.5).

A good example of products with a thickness of 1 mm is the 10x14x1 modification. The exact dimensions will be 10.3x14.6x1.0. A single copy weighs 0.67 g. The release of 10x14 washers is made at least in batches of 10 pieces.

Important: only Russian manufacturers try to keep these dimensions exactly.

The product is also popular with the size of 5x10x1, as well as 10x12x1, 38x52x3. Products of the M10 category, including M10x14, differ:

- with a diameter of 10 mm (not without reason taken out in the designation);

- weighing 3 grams;

- with an inner diameter of 20 mm.

Finally, copper washers in the following sizes are in demand on the market:

- M8;

- M12;

- M14;

- M16.

A detailed process for annealing copper washers is presented in the following video.

The comment was sent successfully.