Accessories for sharpening planer knives

Wood details are popular. To improve the quality of the upper layer of a wooden surface, planes are used - special tools in the design of which a blade is provided.

Through the work of this blade, it is possible to remove the top layer and make the structure smoother, remove rough edges. With prolonged use, the blade deteriorates, its cutting edge is ground, which leads to the impossibility of further operation of the tool.

Remarkably, wood has a strong negative effect on knives and accelerates their wear. It rises when the blades hit a hard element such as a nail or a hook during wood processing.

If the knife has become worse to work, its surface is dull, you should resort to sharpening the blade. Regular cleaning of the planer blades will prolong the life of the tool and maintain its basic properties.

Peculiarities

Today there are several attachments for processing blades. They are classified according to various criteria. The most common are the following.

- Devices are classified according to the type of use. There are manual and mechanized machines. The first option is easy to use, as well as low cost. The advantage of the second is the high speed of processing steel material, which is why such tools are more popular.

- The second classification involves the separation of devices according to the grain size of the abrasive material. Large grit results in rapid removal of steel from the blade, and the reduction in abrasive stones contributes to a decrease in the thickness of the metal layer.

- The third classification option is home-made or purchased devices. If required, you can assemble the machine yourself, and this option is even cheaper.

Today, many companies are engaged in the production of sharpening devices. However, you should not give up manual sharpening. Such a device has a number of advantages:

- it is suitable for cutting edges and can be used to sharpen other knives;

- the mechanism removes a small amount of metal, in the process you can use several abrasive elements of different grain sizes.

Basically, a manual device is used when it is necessary to process or remove a layer from complex structures. Electrical equipment will not allow you to achieve the required accuracy, therefore, inferior in this situation.

Sharpening and adjusting knives

First of all, it is worth clarifying that sharpening is not only the processing of the knife, but also the adjustment of its position, taking into account the requirements and characteristics of the tool. The adjustment, in turn, is the adjustment of the degree of protrusion of the cutting element from the device. The features of the sharpening procedure include:

- removal of metal;

- exposure of the desired angle.

Regarding the second point, it is worth noting that with an incorrect angle, the efficiency of using the device decreases. Mechanized sharpening greatly simplifies the process, since it is possible to provide for reliable fastening of the workpiece and setting the required angle for work. At the same time, some machines also allow you to change the nozzle, preventing the removal of a thick layer from the knife.

Types and their structure

Knives are the main element of the plane, so it is worth taking a closer look at their design, structure and features.The cutting part of the blades is subject to wear during operation, so the material needs to be sharpened periodically. Today there are two types of planers that use special blades.

Mechanized

They are electrical tools. Designed to handle large amounts of wood, the blades are thicker and made of stronger steel. Due to the motor provided in the carriage design, the operating speed increases, as well as the wear of the cutting elements.

Manual

A fairly common type of tool that, if desired, can be made at home. For the manufacture of the body of the planer trolley use:

- metal;

- wood;

- plastic.

The blade has a small thickness; special steel is used to create it. A distinctive characteristic of the knife is resistance to wear. The difference between the two tools is not only in the presence or absence of an engine.

Electric planers are distinguished by the presence of multiple cutters and the ability to use double-sided blades. All of this increases work efficiency, which is why power tools are popular.

During operation, it is not immediately possible to determine that the planer knives need sharpening. However, there are several sure signs that will help you understand the need for sharpening.

- Chamfer appearance. If, during inspection, a shiny tape of small thickness is found on its surface, then sharpening is necessary.

- The appearance of a reversible knife. In this case, determining the need for sharpening is simple - just look at the metal after turning the element twice in the plane.

To sharpen knives, they use special devices and tools, and also take into account a number of recommendations. Ignoring the latter can result in poor blade performance, so it is important to remove the steel correctly.

Operating tips

The plane requires taking into account the operating rules. The same is required for the sharpening procedure. It must be borne in mind that the processing of knives should only be carried out using the following tools and materials:

- a bar, the surface of which is covered with fine abrasive grains;

- emery;

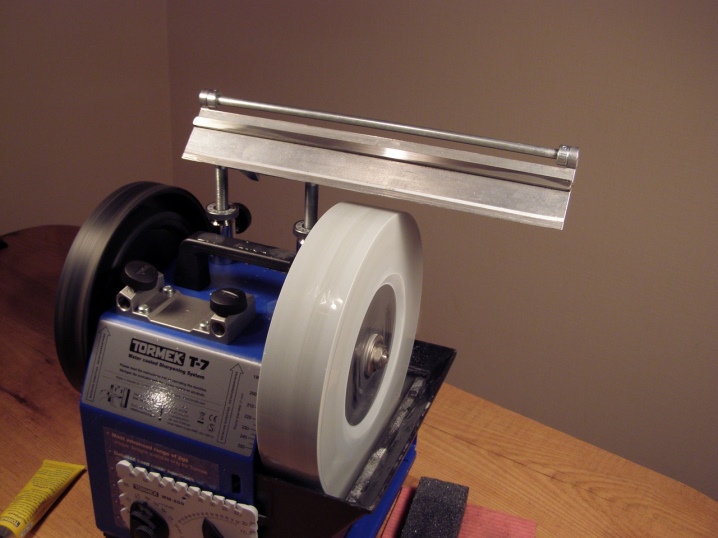

- grinding wheels;

- leather belt;

- polishing paste.

Additionally, you need to prepare another belt with which you can grind the surface. Sharpening ensures the restoration of the sharpness of the cutting edge.

If defects appear during processing, then it is necessary to use a grinding wheel. It will help get rid of protruding burrs, and also prevent the knife from bending. Effective sharpening involves the use of emery, equipped with two wheels:

- the first has an insert of coarse abrasive grain;

- the second is the insertion of smaller particles.

This combination provides the desired effect and increases the sharpness of the blades. Sharpening requires a responsible approach, since ignoring the requirements and features can lead to breakage of the blade and tool. An important parameter that must be taken into account when using sharpening tools is the angle at which you need to sharpen the knife. Most often, this figure should not be below 25 and above 45 degrees.

The angle is selected according to the hardness of the material being processed, in this case, steel. Maintain the corner by means of the holder that each master has.

There are several guidelines to help you sharpen your planers successfully.

- When carrying out work, it is better to avoid strong pressure if you do not want to remove a thick layer of material. This error also leads to blade breakage during use of the planer due to reduced strength and improper stress distribution.

- When the knife comes into contact with the circle, its surface will heat up, which will lead to an increase in the ductility index.To prevent the blade from bending, it is recommended to cool the metal more often in a bucket of water.

- After the main sharpening, the surface of the blade should be refined, getting rid of obvious defects. This can be done using a fine-grained bar.

The final step is to use a leather belt and sanding paste. With their help, you can make the blade as smooth and shiny as possible. Sharpening is difficult to execute. However, it must be done regularly to prevent wear on the planer and improve work efficiency.

In the case of blades of electric tools, it is better to contact a specialist for sharpening. This is explained by the fact that even a minor defect that may arise during processing can damage the structure. And such planes are expensive.

Checking blade alignment

After sharpening, the knife must not be started immediately. It is required to check and adjust the position of the blade in the planer. When the blades have been processed and installed, it is necessary to carefully examine the plane and estimate the distance that the knife moves out of its position. The optimal parameters are as follows.

- The blade protrusion must not exceed a distance of 0.5 mm. If a rough cut is required, then the cutting element can be extended by 1 mm.

- A large gap results in large chips. To improve the quality of work, you should reduce the gap between the surface of the wood and the blade. Then the chips will be minimal, and this will reduce metal wear.

Additionally, it should be borne in mind that when comparing a planer with other tools, it will differ from them in the possibility of using it for fine processing. This can only be achieved by correctly adjusting the location of the knives in the tool design and by choosing a suitable angle. When all the procedures for sharpening and adjusting the knives are completed, it is necessary to assess the performance of the planer. To do this, it is worth trying to process the surface of the wood. If it becomes smooth during processing, it means that the sharpening was done correctly.

The nuances of sharpening a hand planer knife in the video below.

The comment was sent successfully.