Miter box: what is it and how to use it?

Any construction work and repairs are not complete without cutting foam, plastic or wood materials. For this, craftsmen use a special miter box tool. Thanks to this device, it is possible to conveniently fix and cut the required workpiece.

What it is?

The miter box is a popular joinery tool that is designed to cut materials at different angles. This tool allows vertical cuts at 45, 60 and 90 and horizontal at 45.

Most often, a miter box is tried on for sawing off platbands, floor, decorative skirting boards, as well as wooden planks and blanks, in which the connection is provided during installation "on the mustache". To date, the tool is produced in a huge assortment and may differ in both the type of device, material of manufacture, and design.

Device and characteristics

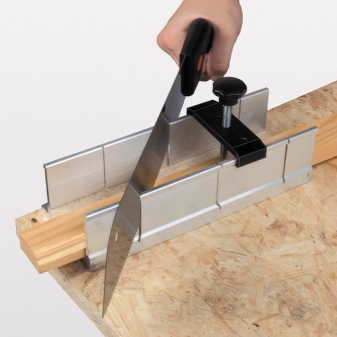

The miter box has a simple design in the form of a tray, to which the sides with cuts are attached. A saw blade is installed on them at a certain angle. In a professional tool, the base is complemented by a swivel mechanism that allows you to cut at any angle with an accuracy of 1. The saw in such models is fixed by a guide element.

The miter box, as a rule, is produced from a durable material that has increased rigidity, most often the following tool options are on sale.

- Made of wood... It is characterized by reliable operation (wood has a high strength index) and guarantees precise cutting of parts. Most of the products are made from beech. If one-time work is planned, then you can make a miter box yourself from plywood.

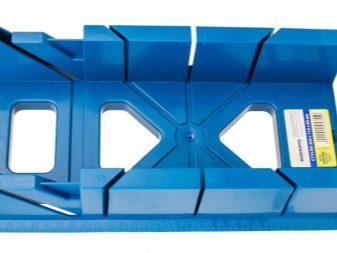

- Plastic... It is considered the most common type of device sold at an affordable price. The plastic miter box has a hollow structure, the thickness of its walls does not exceed 1 mm. Since the strength of the plastic is low, the grooves are quickly ground under the influence of the saw teeth, and the tool becomes unusable. The main feature of such devices is the presence of clamps, they easily clamp and hold workpieces.

- Made of metal... For the production of metal models, aluminum is mainly used, since it is distinguished by its durability and reliability.

As for the general characteristics, the average weight of the device can be from 0.1 to 0.6 kg. It depends on the size and material from which the device is made. Swivel models weigh from 2 to 4 kg.

The miter boxes are as follows in size.

- Small... Their dimensions are 212 × 44 × 42 mm (length × width × height). These tools allow you to cut 35 × 35 mm.

- Average... They are available in sizes 290 x 85 x 50 mm and can cut workpieces 65 mm wide and 40 mm high.

- Large... They are 320 mm long, 125 mm wide and 70 mm high. With the help of such miter boxes, you can cut material 90 mm wide and no more than 55 mm high.

The above parameters may vary depending on the features of a particular model. As a rule, most manufacturers produce tools in lengths from 290 to 310 mm. There are also tall devices on sale with a height exceeding a few centimeters in width.In this case, the base is made wider than the tray, which increases its stability, and aluminum is used as the material of manufacture.

Appointment

The miter box is the most common carpentry tool used for various construction work. Depending on the model, it can cut various materials both at right angles and at a given angle.

The miter box can be used in the following cases:

- for the formation of docking, internal and external corners in the door frame and skirting boards;

- for cutting baguettes, large cornices, glazing beads, pipes and metal profiles;

- for cutting boards and plastic material.

In addition, this device allows you to make various decorative elements and frames. It is often used for trimming stucco elements. This tool can also perform other types of carpentry work that require precision and are not suitable for circular saws, hacksaws for wood and metal.

Views

Today manufacturers present various types of miter boxes on the market, from simple to professional models. A plastic miter box with a hacksaw is very popular with craftsmen. Its main advantage is its affordable cost, despite the fact that the plastic device is in many ways inferior in strength to others, it can cut both wooden and metal blanks.

This device is mechanical and, as a rule, is chosen for repair and construction work at home. If volumetric cutting of workpieces is planned, then it is best to purchase a professional aluminum or wooden miter box.

The professional-looking joinery is distinguished by its quality and technical characteristics. It is highly accurate, adjustable and available in large sizes. It has a high canvas, in some models it is wide. In addition, the manual device is additionally equipped with two eccentrics, which increases the reliability of fixing the workpieces. The advantage of these types is angular spraying, which can be done at precisely defined dimensions and angles.

Common

This type of tool has a simple design, in which the base is made of a U-shaped metal, plastic or wood profile. Often an ordinary miter box is called "box-shaped", this is due to its shape.

In this view, a template device is provided, therefore cuts can be carried out only along the laid cuts, without the possibility of adjustment... Using a conventional miter box, as a rule, workpieces are cut at an angle of 30, 45, 60 (in any direction) and 90 in the center. The manufacturer completes such models with a saw. They are characterized by a long service life and are sold at an affordable price.

Swivel

Such a device differs from the usual one in that it provides the ability to adjust the cut at a selected angle. Precision tool type allows you to change the cutting angle in two planes.

The device comes complete with an adjustable stand and a saw. The cutting material can enter at any angle, both vertically and horizontally, this makes the tool two-plane and simplifies the formation of bevels on a workpiece of any configuration.

Such a miter box is well suited for complex carpentry work.

Electrical

In addition to hand tools, there is also an electric tool on the market. Its design is represented by an adjustable stand and a miter saw. Thanks to this saw attachment you can cut various materials at any angle.

The electric miter box is indispensable for precise cutting of the same type. It is most often used in construction and industrial work when forming comb and dovetail joints.

Universal

This is a rare type of instrument, it looks like a frame on which two discs are attached.Between them is the slab canvas, in which the angle can be set in two planes. Such a miter box is less convenient to use, since it requires preliminary adjustment.

It is usually used for simple carpentry work.

Magnetic

Compared to previous models, in this device the hacksaw blade is held by special magnets. Such moths can differ both in terms of usability, design and purpose. The most common models are those in which a square with magnets is placed on the base on both sides. To expand the functionality, most manufacturers supplement the tool with auxiliary elements.... For example, in the design of the miter box, there may be a retainer in the form of several movable clamps installed in the body.

The magnetic miter box with eccentrics is very popular among craftsmen.... They are placed in the horizontal plane of the base and outwardly resemble rounded wedges. During turns, the eccentrics clamp the part to the side, providing good fixation.

Tilt tool has also proven itself well, the tilt angle in which changes horizontally. These models are equipped with special streaks and teeth on the file, which increases their productivity.

Which one is better to choose?

The construction market is represented by a chic assortment of joinery mills, so it is often difficult to make the right choice in favor of a particular model. Before purchasing this tool, you need to decide on the type and amount of planned work.

For an apartment and a summer house, you can choose the simplest miter box designed for sawing blanks at common angles. It is ideal for matching plastic ceiling moldings and trims.

If you want to cut the material at all possible angles, then it is best to give preference to professional models, the right solution in this situation will be two-plane precision tools.

In addition, when buying a device, it is important to pay attention to the following parameters.

- Product material and wall thickness... Chairs made of metal and wood have proven themselves well. They are characterized by high strength and long service life. As for the thickness, it is advisable to choose a tool with sealed walls.

- Maximum cutting height and width... This indicator is set depending on the size of the workpiece, but the tool must have the ability to adjust.

- Saw... In order not to overpay, experts recommend buying miter boxes that are sold complete with a saw. As a rule, it is equipped with a backing and is easily installed in the canvas thanks to special puzzles.

- Stroke... When cutting or sawing material, the saw must move freely without play.

- Retainers... In many models of the tool, additional fastening elements are provided that securely fix the workpiece. To facilitate the workflow, it is best to give preference to miter chairs with clamps.

- Number of corners... The more, the better. It is important to ensure that the tool has visible corner markings.

As for the manufacturer, on the market you can find miter boxes of both domestic and foreign brands.

In terms of product quality and positive reviews, the rating of firms is presented as follows: FIT, Zubr, Gross, Stanley, Kuper, Profi and Stayer... They produce various types of miter boxes for household and professional use. All products are certified, have a high wear resistance and are designed for a consumer with an average income.

How to use?

After the miter box is selected and purchased, it is important to study the basic rules for its operation. This will ensure safe work and improve the quality of the cut.The device is attached to a table or a special rack using self-tapping screws or clamps. Then markings are made on the workpiece and it is placed in a tray, pressed against the side, aligning the mark with the groove.

After that, the saw blade is mounted in the grooves and cutting begins, while in order to improve the accuracy of the cuts, it is necessary to choose a special hacksaw equipped with a butt.

In a similar way, beginner craftsmen usually perform work at home; more complex sawing requires both a professional tool and a certain experience. The cutting of parts with a complex configuration is carried out using a tool with a rotary mechanism. Angles and cutting paths are independently set on it.

To cut workpieces with an electric miter box, you should adhere to the following rules.

- First you need to study the instructions that come with the device. This is necessary in order to know how to set the cutting angles and carry out laser marking.

- Then the wort is fixed on the table and the outline of the cutting lines is started according to the drawings.

- On the digital panel, the fixtures set the desired angle and proceed to work directly.

Regardless of the type of miter box, when using it, you must adhere to safety precautions. For this, protective goggles and heavy gloves are worn.

Work can only be carried out with a well-fixed tool. In the event that the miter box is not equipped with clamps, the workpiece should be held by hand when cutting.... To do this, with a thumb placed at a safe distance, they rest against the cutting material, pressing it tightly against the side, while the rest of the fingers should cover the side itself. In addition, before work, the saw should be installed in the grooves along the height of the teeth.

To protect the master from jumping out of the groove, the marking is recommended to be carried out with smooth, slow movements. A properly selected miter box model will also help to facilitate cutting.

An overview of the miter box and the rules of use are presented in the video below.

The comment was sent successfully.