The subtleties of choosing and using Phillips screwdrivers

Every modern person at least once in his life came across such a tool as a screwdriver. In most cases, for household needs, to unscrew or tighten screws. But even holding this universal device in hand, no one thought about all its features.

Peculiarities

Phillips screwdrivers are in great demand among their fellows with other types of tips. It is she who can unscrew and tighten a variety of fasteners of various types. It is simply impossible to disassemble a lot of household appliances, electronics, and other devices without the help of a Phillips screwdriver.

The main feature of this tool is the special shape of the tip, made in the form of a "+" sign. Accordingly, fasteners with a similar slot will help to remove the cross assistant.

The handle of Phillips screwdrivers is made of different materials, while it does not slip in the hand, it is conveniently located when gripped by the palm, without causing discomfort during prolonged use.

Specifications

The wide demand for cruciform models is due to the fact that their tips help to install a considerable number of screw fasteners and self-tapping screws. These products are specially marked with a cross and the letters PH. These designations indicate the size of the products. The smallest size is marked with 000, which means 1.5 mm. Such small fasteners can be seen in cameras and cell phones. In order not to get confused in sizes when seeing only product markings, you should know their approximate ratio:

- 00 - 1.5-1.9 mm;

- 0 - 2 mm;

- 1 - 2.1-3 mm;

- 2 - 3.1-5 mm;

- 3 - 5.1-7 mm;

- 4 - above 7.1 mm.

In the construction industry, screwdrivers of the second size with a magnetic tip and a tip length of 200 mm are very popular. As for the largest marking, it is found mainly in large industries, at car service stations or in workshops for the production of large-sized spare parts.

Phillips screwdriver markings indicate not only the size of the tip, but also the thickness of the rod. But its length is chosen taking into account the upcoming work. Screwdrivers with small handles are indispensable in tight spaces, and long models with a tip of 300 mm are used when access to fasteners is difficult.

Now you can go to the PH designation that is present on every Phillips screwdriver. The presented Latin letters stand for Philips, that is, the name of the company that owns the patents for screws with cross-shaped recesses and screwdrivers for them.

Modified models of cross products are equipped with special notches, which are responsible for a tighter fixation in the head of the screws, as a result of which the handle does not slip out of the hands.

In addition to the abbreviation PH, Phillips screwdrivers have the letters PZ, that is, Pozidriv. In this type of cross tool, there are additional rays that are responsible for a stronger fixation in the fastener. This modification is mainly used for the assembly of cabinet furniture, drywall and installation of aluminum profiles.

When making a choice in favor of a particular manufacturer, you should pay attention to the quality of the offered product. It is better not to consider Chinese manufacturers in this matter.Japanese and European screwdrivers have a number of undeniable advantages that will suit the most demanding customer. When choosing a domestic tool, you need to make sure that there is a GOST marking, which speaks of one hundred percent quality.

An important characteristic to look out for is core strength. Its standard is calculated from indicators of 47-52 units. If the indicator is indicated less than 47, then with a slight physical impact, the screwdriver will bend, and over 52 units - it will crack.

In most cases, the indicator of the strength standard is indicated in the form of the Latin letters Cr-V.

What are they?

The daily work of any craftsman involves the use of different types of screwdrivers. This applies not only to the shape of the tip, but also to the technical characteristics of the instrument. In addition, curved screwdrivers are classified according to their application areas. For example, it is strictly forbidden to disassemble cell phones with a shock modification. To acquire deeper knowledge, you should familiarize yourself with each type of screwdriver separately, after which you can safely select the required model.

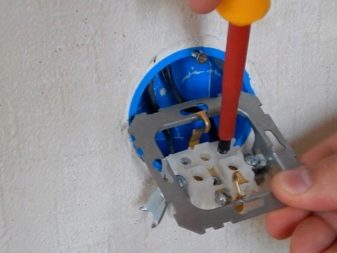

- Dielectric screwdriver designed and designed specifically for repair work in the electrical network and any electrical installations under constant voltage. It is important to note that the maximum tolerance of this tool model is 1000 V. Above - you must use other means for work, and it is best to temporarily turn off the power.

- Impact screwdriver equipped with a special function that helps to unscrew stuck and rusted bolts. The principle of operation is quite simple, with some physical impact, the bit turns in the right direction by 2-3 mm, thereby untwisting the adhering bolt, without cutting off the thread.

- L-shaped screwdriver in everyday life it has a second name - the L-shaped key. The design of the model is equipped with a hexagonal slot. Additional ball tips can be used to tackle challenging jobs at specific access angles. Uses these screwdriver models for easy access in confined spaces.

- Angle screwdriver its structure resembles a ratchet from an automotive toolbox. It is used in many types of work, since it can be small and large in size. The curved design allows for work in hard-to-reach places where the vertical position of the tool is in no way suitable for loosening bolts from a horizontal surface.

- Power screwdriver was developed using a special technology that allows you to increase the torque of the tool by acting on it with a hexagonal rod. In simple terms, the power modification of a Phillips screwdriver is mainly used in large industries, where human power is often required. By fixing a special key, the torque of the screwdriver is increased, due to which the process of mounting and dismounting is reduced several times.

- PH2 cruciform model mainly used for small construction work, as well as in everyday life. The peculiarity of this product lies in the ability to screw screws into a soft and thin surface, for example, thresholds in rooms.

- Magnetic screwdriver is considered a universal design. Any of the above modifications can be magnetized during production or at home after purchase. These models can be presented in completely different forms. The thin bar is ideal for mounting and dismounting small cross-fastening parts.

Taking into account the additional nuances of the work ahead, you can determine which screwdriver will fit in size: long or short, with a plastic handle or with a silicone filler.

Gadgets

Modern modified Phillips screwdriver models are presented in the form of a solid rod with replaceable bits, which are stored in the handle of the tool. Of course, it is convenient to have a large set with different sizes of screwdrivers with you, but a similar option will do for home use.

In addition, each bit has a magnetized tip and, if necessary, can be used in conjunction with a screwdriver, especially during initial installation.

Another indisputable plus is the high interaction with modern metal anchors.

Convenient and durable coupling allows for easy installation.

How is it different from a flat one?

In the modern world, the most common types of screwdrivers are flat and cross models. The difference between them is quite obvious. The blade of a flat screwdriver is presented in the form of a straight tip made of a narrow plate. In the recent past, almost all fasteners had a straight tip line, and it was only required to select the required tip size. Nowadays, such fasteners are used quite rarely, but if they are installed, then only with a flat screwdriver.

Cross models, in turn, are designed for mounting and dismounting of figured mountings. Due to the larger number of projections on the sting, they have a tighter grip with unscrewed elements.

Unlike flat screwdrivers with cross-head tips, you can work not only with household items, but also perform work on wood and metal.

In turn, flat screwdrivers are suitable only for installing door handles, sockets and similar items.

Selection Tips

To begin with, it should be noted that it is unprofitable to purchase only one screwdriver for the purpose required at the moment. After a few days or even a month, you may need to use a different size model. Therefore, your attention should be paid to a special set, which includes screwdrivers of all sizes and additional bits. Each master will confirm that it is not possible to start the repair process without a screwdriver, or better yet, several pieces.

To carry out minor repairs to household appliances, you should not pay attention to huge sets. It is enough to have two or three models, often used at the household level. Their price shouldn't hit the pocket either, because to unscrew a screw in a coffee grinder, you don't have to use brute force.

For builders, Phillips screwdriver sets should be chosen with a firm grip that can withstand heavy loads and pressure.

For electricians, a regular screwdriver is not suitable in any way. In this case, it is necessary to use a special model made of insulating material. Thus, the specialist receives protection against electric shock.

To repair laptops, watches, cell phones and any radio equipment, use Phillips screwdriver modelsdesigned for precision work. Their distinguishing feature lies in the powerful magnet of the tip and the thin shaft. In addition, precision screwdrivers are equipped with a special ratchet that allows you to unscrew small fasteners without removing the rod.

For complex work with powerful types of fasteners, you must use the impact model of a Phillips screwdriver.

They also have a kind of ratchet that turns the fasteners by about 3 mm, while not ripping off the base threads or damaging the recess for the sting.

Subtleties of operation

The ingenuity of a modern person often exceeds all expectations. Items and tools designed for the same purpose are used in a completely opposite profile. For example, with the help of a screwdriver, many people scrape off various kinds of dirt from different surfaces, separate stuck parts and even use them along with a chisel.

All these actions are contrary to the natural work of a screwdriver, respectively, the tool quickly deteriorates. All that remains is to make a choice between buying a new one and tidying up an old instrument.

Everyone can fix the handle of a screwdriver, but not everyone can sharpen a damaged sting. Many try to carry out the rescue work correctly, but the result is not always crowned with success.

Sharpening a screwdriver is not an easy task, much like the principle of processing a blade on skates. Only with cross-type models should you be extremely careful. Initially, the metal heats up to reddening, then it is dipped into the lubricating liquid, then it cools a little and sharpening begins. The complexity of this procedure lies in the small size of the handpiece beams and the inconvenience of approaching them.

After sharpening, the finished tool should be magnetized. To do this, put a screwdriver next to the magnet and leave it for a while.

To avoid such problems, it is best to use screwdrivers for their intended purpose.

How to sharpen a Phillips screwdriver, see the video below.

The comment was sent successfully.