All about wire BP 1

Wire made of metal is a versatile material that has found application in various industrial and economic fields. However, each type of this product has its own characteristics, characteristics and purpose. Here we will consider what parameters a low-carbon wire of the BP 1 brand is characterized by, as well as what requirements are imposed on its manufacture.

Description

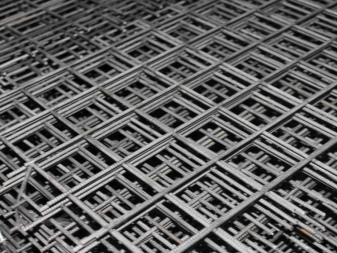

In the production of reinforced concrete products, wire BP 1 is widely used to strengthen the strength of the frame. It can even replace reinforcement, which is why it is also called reinforcing wire.

Explanation of the abbreviation: "B" - drawing (production technology), "P" - corrugated, number 1 - the first class of product reliability (there are five of them).

At first, this wire was used exclusively for reinforcing concrete products, but later it began to be used for the production of fences, cables, nails, electrodes and much more. And the reason for this was the cheapness of its production and versatility. Very often, such wire is used to strengthen facades, reinforcing the foundations of buildings and floors. It is used to make welded mesh for concrete products and road surfaces, as well as knitting material.

The profile of this product is ribbed, has a periodic step of protuberances and recesses. Thanks to these notches, the wire-reinforced framework more reliably engages with the concrete mortar. As a result, the finished concrete products are stronger.

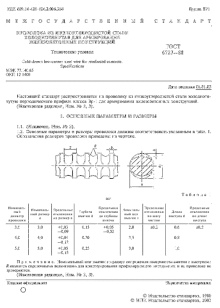

According to the standards of GOST 6727-80, products of this type are made of steel, in which the carbon content is very low - a maximum of 0.25%. The cross-section of the wire can be either oval or polygonal, but most often it is round, which is most convenient to use.

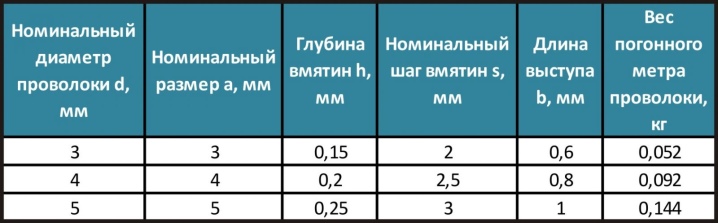

According to the standard, the wire is produced with the parameters indicated in the table below (all dimensions are in mm).

Diameter | Dimensional deviation of diameter | Depth of dents | Depth tolerances | Distance between dents |

3 | +0,03; -0,09 | 0,15 | +0.05 and -0.02 | 2 |

4 | +0,4; -0,12 | 0,20 | 2,5 | |

5 | +0,06; -0,15 | 0,25 | 3 |

There should be no defects (cracks, scratches, cavities and other damage) on the surface of the product.

Having studied the standard, you can find out that a metal product of this type is able to withstand at least four bends, as well as the amount of tensile force, which is the limiting one depending on the diameter.

Features of production

Since the wire BP 1 is very popular, many metal rolling enterprises are engaged in its manufacture. The latest equipment allows you to get up to several tens of meters of this product in 1 second, while performing all the notches quickly and efficiently. Drawing technology is considered to be more advanced and economical.

The production uses rolled rods made by the hot-rolled method. They are additionally processed so that the quality of the products remains at a high level. For example, the scale, if any, is very carefully and carefully removed from the surface.

Then they start making wire by drawing through holes (dies) on special drawing mills. These holes are gradually reduced in size and allow you to get the product of the desired cross-section. This technique involves pulling the raw material through several dies with dies of different sizes, achieving even a very small cross-section of the product.

In addition to GOST, there are also various local TUs, guided by which, enterprises can produce products of non-standard sections in the range from 2.5 to 4.8 mm.

Dimensions and weight

The BP 1 product grade should be produced in coils weighing from 0.5 to 1.5 tons, but it is possible to produce a smaller weight - from 2 to 100 kg. Taking the averaged parameters, we can draw a conclusion on the length and weight of the product, depending on the diameter of its section:

3 mm - in a skein will be approximately 19230 m, and the mass of one running meter (l.m) - 52 g;

4 mm - the length of the product bay is about 11 km, the weight of 1 linear meter will be 92 g;

5 mm - in a wire spool - within 7 km, weight 1 line m - 144 g.

Domestic enterprises do not produce BP 1 in rods - this is unprofitable, high costs are required.

But if the customer wishes, then nothing prevents the sale from unwinding the coil, straightening the wire and cutting it into pieces of the required length.

You can find out how easy it is to align the wire with your own hands from the video below.

The comment was sent successfully.