Production of a swing from a profile and polypropylene pipe

A swing in a suburban area is a necessary attribute of summer pastime. They can be made portable, but they can also be designed stationary. If you make such a structure yourself, then its cost will be low.

It is only important to decide on the location of the object, and what the structure will be.

Peculiarities

If the family has children, then having a swing is a great option for spending leisure time. There are a huge number of garden swings on sale. But assembling a structure with your own hands is always interesting and exciting. There are several types of metal garden swing that you can make yourself:

- for the whole family (massive structure, which consists of a wide bench, where both adults and children can fit);

- for children (small swing, which consists of one or two seats, only a child can ride on them).

Pros and cons of products

First of all, let's take a look at the positive aspects of self-made products:

- metal swings are durable,

- designs can be made unique, which will add harmony and comfort to your summer cottage,

- a hand-made product is much cheaper than in a store.

However, there are also negative aspects:

- the frame made of metal is rather rigid, so you should be careful about possible injuries and bruises;

- special processing of the material is required to avoid corrosion.

One of the most reliable materials is a metal profile pipe.

She has the following advantages:

- long term of use;

- high resistance to mechanical damage;

- the quality corresponds to the cast profile, while this material is much more profitable in price;

- not subject to corrosion after special processing.

These are the main advantages of a metal profile pipe, but there are no ideal materials, so there are also disadvantages:

- hard to bend;

- it is imperative to use paints and varnishes or galvanized; without this, ferrous metal lends itself to rust and destruction.

Variety of models by type of attachment

Garden swings differ not only in shape and size, but also in the type of attachment.

Stationary

The stationary swing is equipped with two wooden posts (or pipes with a cross section of 150-200 mm), which are installed in the ground and concreted.

The advantage is that they can be placed wherever you want. In itself, such a structure is solid, the service life is calculated in many tens of years. It can withstand significant loads.

A stationary swing can accommodate up to four people, often equipped with a canopy or canopy to protect it from the elements.

To put the beams, two small pits 1.4 meters deep, 45 cm in diameter are dug into the ground. Fine crushed stone is poured (40 cm layer), it is well crushed. One end of the bar is primed, wrapped in waterproofing, placed in a pit. Then the concrete should be prepared:

- 5 pieces of fine gravel up to 20 mm;

- 4 pieces of sand;

- 1 part cement.

The bars are placed in the pit, centered using a two-meter level, fixed, and poured with concrete.You should wait 2-3 weeks before subjecting such supports to any stress.

It is better to make this structure in the fall, according to the technology, concrete is "suitable" for another five months, that is, this process will just stretch over the entire winter period.

Mobile, suspended

Such a product stands alone and does not require any additional support for suspension. Moreover, this model can also be moved to any place. The configuration can be different. The swing, which is attached with chains, is durable. A more massive structure can be hung on them (they can withstand a load of up to 300 kg).

Among the disadvantages are the following nuances:

- large links can cause injury: if you hold onto the chains while swinging, then there is a possibility of fingers getting between the links;

- use is possible only in cold weather, because the links are heated by the sun.

Garden swings, which are attached with a rope, are quite popular in use, because the price of such a material is low, and the construction with this mount is very simple.

Pros:

- affordable price;

- safe use;

- does not require special support when suspended;

- easy to repair.

Minuses:

- short-lived;

- a heavy structure must not be suspended.

Choosing a place for a structure

Before installing a garden swing, you need to decide on the place where they will be located. There are a few tips to keep in mind:

- it is better to place the swing near the house;

- do not install an iron swing near communications (power lines, water supply);

- if there is a road nearby, then a fence should be installed.

It is important that the groundwater does not come close to the surface, and the soil is not swampy. The ideal option would be to make a swing on a small hill.

Design

Before proceeding with the design, you should decide on the type of frame, which can be collapsible / prefabricated (using bolts and nuts) or using welding. If we talk about the first type, then the principle of assembly is to make parts of the appropriate length and calculate the correct pipe diameter for bolting and nuts.

The welded structure is more durable and stable, and welding equipment is required for its manufacture. If you want to make not an original, but a completely standard product, then drawings are not required, on the Internet you can take a ready-made scheme as a basis.

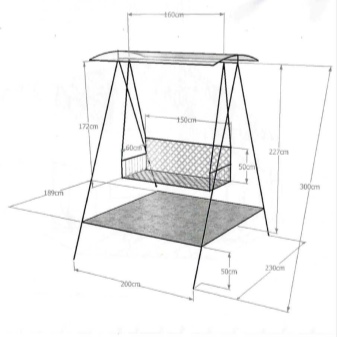

To draw a sketch of a swing, you will need to take into account the following dimensions:

- the square seat is 55 cm;

- the height of the seat must be made about 60 cm;

- for a mobile structure, it is necessary to observe the distance between the support posts to the edge of the seat from 16 to 42 cm, it all depends on the type of attachment (rope, chain).

Preparation of materials and tools

To prepare a tool for making a product, you need to understand what the material and fasteners will be. The main tools that will be required:

- angle grinder in order to saw off parts of the desired length;

- welding machine (if required for connection);

- measuring tool;

- a hacksaw (if there are wooden elements), as well as a grinding tool;

- hammer;

- screwdriver;

- electric drill (in the case of fastening the racks with concrete, you will need a mixing nozzle);

- screwdriver;

- parts for fasteners made of stainless steel;

- bent reinforcement bar (to secure the structure to the base);

- waterproof fabric for the roof;

- special coatings for metal that protect it from corrosion.

A model in the shape of the letter "A" will be practical, here it is not necessary to fill the load-bearing fastenings with concrete. The crossbar is most often a metal pipe, a cable is attached to it. Supports are made of channels or pipes. Functioning is based on the presence of gravity.

To create such a design, you will need:

- pipes with a cross section of two inches;

- metal profiles with a section of 12x12 mm;

- corners "4";

- copper wire;

- bolts and nuts "10";

- reinforcement by 10 mm;

- bars and slats for seating;

- cable or chain;

- pipe with a cross section of 60 mm.

Assemble the swing by placing and securing the supports. At the top points, metal plates are fixed, the crossbars are made of profiles. Thus, the structure will have an acceptable rigidity. The two bearing supports are connected by means of a plate that is welded. The plate must be at least 5 mm thick to support the required load.

The seat can be made single or double. It is made of strips (thickness 40-70 mm) and bars, the nodes are attached using bolts.

They have proven themselves well as load-bearing supports for PVC pipes. The pipes can withstand significant loads, and are also easy to install.

Manufacturing and assembly of the structure

To make a garden or children's swing with your own hands, you need to choose a suitable drawing and decide what materials the structure will be made of. Then you should prepare the place where the swing will be located:

- level the site;

- add a "pillow" of gravel.

It will be necessary to lay out the necessary tools and materials ahead of time. The support for a stationary swing can be made from the following materials:

- PVC pipes;

- wooden beams;

- metal pipes.

The latter will need to be welded in some places, so a special apparatus will be needed.

From a metal profile

To create a structure from a profile, you will need:

- bearing quadrangular frame;

- sidewall of the letter "A" configuration, made of two pipes that are attached using welding;

- one pipe, which will be horizontal and will serve to hang the bench.

The metal profile is a reliable material today. A profile pipe with a cross-sectional size of about 200 mm is also suitable for creating, while the wall thickness should correspond to 1 or 2 mm. The seat base can be made from a pipe with a cross section of about 20 mm. This will affect the smooth rocking motion.

Fasteners are usually made of chains, then it will be convenient to adjust the length of the swing. The seat is also made of wood, this material is quite functional.

Installation process:

- we cut the elements that consist of a pipe (side posts, crossbars, bases);

- we grind wooden elements (these will be the details for the seating);

- we connect the necessary parts by welding or special bolts;

- we connect the racks to the base of the swing, then we attach the crossbars;

- for a stationary garden swing, you need to dig 4 holes;

- beams must be inserted into these holes and filled with concrete.

From polypropylene pipe

Children's swings are required to hold a load of at least two hundred kilograms. The section is permissible from 50x50 mm, the walls - at least 1 mm thick. Swings for adults are made of pipes with a cross section of 75 mm. The seat is made of bars and slats. Consists:

- from a pipe with a length of 6.2 m;

- 8 metal corners;

- reinforcement with a section of 16 mm and a length of 26 cm;

- wooden canvases.

To make good supports, you will need two meters of segments, which will be transverse supports, and one upper crossbar will also be needed. In addition, four 2.3 meter sections should be prepared in order to assemble the fasteners. And two additional segments of one and a half meters to get the side nodes of the base.

Construction should begin with supports, they bear the main load. Before starting work, the pipes should be cleaned from dents. Two structures are welded in the shape of the letter "L", they must be completely congruent. The knots are welded at a 45 degree angle and the crossbar is attached perpendicularly. Two depressions are dug (up to 1 meter), the bottom is sprinkled with sand. The welded structures are placed in recesses and poured with concrete. Wait three weeks for the concrete to "set".

Then fasteners or hooks are screwed to the crossbeam, the seat will hang on them.After completion of the installation, the new structure should be painted. The seat is made of a metal frame, beams and wooden or plastic slats.

To make the "seat" soft, you can put foam rubber under the upholstery.

Care Tips

Before talking about the care of the swing, it is worth dwelling on the operating conditions of these structures. It was said above that such products are not recommended to be placed near communication lines. In addition, you will need to make sure that there are no sharp protruding corners that are easy to cut.

As for leaving, it does not cause much trouble, only a few rules should be followed.

- If the structure is made of metal, then such material should be protected from corrosion using special means. In stores, you can easily find a rust converter, thanks to which a protective film is formed.

- If you treat the structure with enamel or paint, this will extend the service life, however, it is worth remembering that the paint will only last for a few years.

- Check the fasteners from time to time, as the material tends to wear out over the years.

Beautiful examples

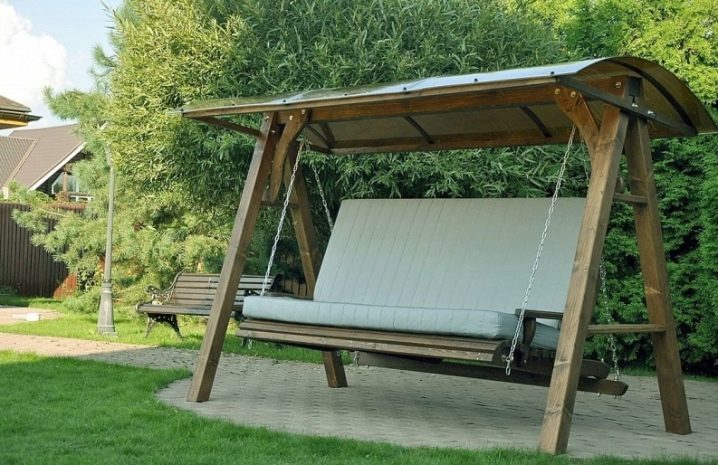

A variant of a swing, where it is not necessary to fill the supports with concrete. This design saves significant money, while the strength and stability does not suffer, while remaining at the same level.

Portable swing option. Such a model is compact and easy to assemble, at the same time, it is reliable and functional.

Children's light swing for the smallest are safe and multifunctional, the child will feel comfortable in them.

For information on how to make a swing with your own hands, see the next video.

The comment was sent successfully.