What is blasting and why is it needed?

For many people it will be very interesting to know what blasting is, and why it is needed, what equipment is required for it. It is necessary to carefully study the features of the installation, the nuances of blasting a log house and a brick. It is also worth finding out what Aquablasting and Armexblasting are.

Peculiarities

Every year more and more new words enter the Russian language. However, it is necessary to clearly understand what is hidden behind each new term, including the sonorous word blasting.

It implies a procedure for blasting all kinds of materials with the use of gentle abrasives. The powerful air jet contains water in addition to the cleaners.

Sand or a special non-harsh reagent is used as a cleaning agent. This technology has been known for a long time, but only in recent decades has its distribution increased. The technique allows you to reliably and fairly quickly free a variety of surfaces from dirt. Blasting machines remove the most difficult old blockages. You can get rid of old paint residues without damaging the surface.

Even very thin items can be cleaned with complete peace of mind. They will not be crumpled or otherwise mechanically damaged. If necessary, surfaces are deliberately roughened to a size of about 1 μm or slightly more. Modern sandblasting systems are necessarily supplemented with modules that collect used abrasive. Practice has shown irrefutably that manual cleaning is completely unjustified - it takes a lot of time and effort.

Cleaning methods

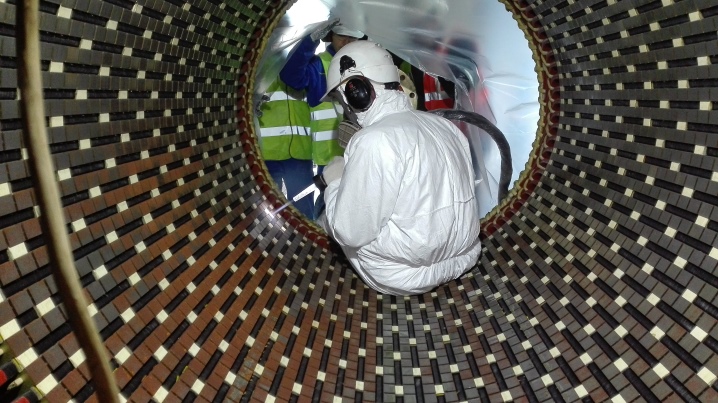

Armexblasting is quite widespread. It is also called soft or soda blasting.

This is the method of choice when you want to clean sensitive products without damaging their surfaces.

This solution is acceptable if you need to clean up:

- showcases;

- window;

- art products made of wood;

- wooden and metal sculptures;

- objects and structures of historical, architectural and artistic value;

- stone;

- ceramic tiles and other types.

In this embodiment, only reagents with a reduced degree of abrasiveness are used. However, the speed of movement of their particles is still very high. Therefore, it is critically important to choose the appropriate mode and work as carefully as possible. The operating costs for soft blasting are very low compared to traditional surface cleaning techniques. The processing will touch even the most inaccessible areas of products and structures.

Some sources may mention Aquablasting. But this is not the name of a specific technique, but one of the firms involved in performing such work.

Another common option is dry ice. The cryogenic option is in demand in developed countries. Ice granules do not have an abrasive effect, and therefore damage to the surface to be cleaned is completely excluded, cleaning occurs due to the melting of ice and the heat released during this.

The rapid fluctuation in the degree of heating provokes a thermal shock. Therefore, mud layers are destroyed and fall off. The materials to be cleaned themselves are not normally cooled, and there is no need to fear changes in their physical properties. It should be understood that cryogenic blasting is carried out with expensive equipment. Products of advanced brands cost up to a million rubles - and this is an average figure.

Blasting equipment

It is most appropriate to compare this equipment with sandblasting. But there are a few differences:

- mechanical deformation of the treated surfaces and structures is excluded;

- heating of the items and elements to be cleaned is prevented;

- the situation is excluded when the surface receives an additional electric charge;

- reduced consumption of cleaning material;

- there is no need for special disposal of cleaning agents;

- there is no risk to people and the natural environment.

Soda blasting machines cost from 500 thousand to 1 million rubles.

Some classifications distinguish a technique using the advanced Armex reagent into a special group. This composition is chemically active, but carefully thought out, and therefore completely non-toxic.

To work with them, the equipment of the brands Torbo, OptiBlast, SBS is used. Paying for such devices costs less than 500 thousand rubles, only some models are cheaper, and even then not by much.

Blasting equipment is sold by:

- "Promcleaning";

- Ecotech24;

- BlastingService;

- "Karex";

- "Cryoproduct";

- BlastCor.

Scope of application

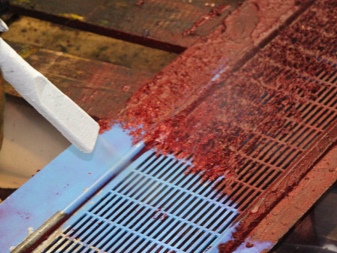

Blasting is often used to clean old bricks. From the surface of the wall you can remove:

- graffiti;

- mold nests;

- old paint;

- soot and soot;

- traces of petroleum products;

- glue residues;

- signs of surface corrosion;

- technical and organic oils;

- unpleasant odors (for example, fumes).

It is often necessary to clean the brick from paint and plaster indoors. This is very important for subsequent loft-style design work. Any efflorescence is reliably eliminated after blasting. This technique is suitable for:

- entrance of an apartment building;

- log cabin;

- facade;

- elimination of fat deposits from any walls;

- cleaning workshops, workshops and other industrial premises.

Soft blasting will not harm various mechanisms and their parts. Moreover, it not only removes rust, but also prevents its reappearance. Sophisticated reagents do not damage engine parts and hydraulic systems. The cleaning mixture can be used with little or no water. Blasting is also used to clean cars, boats, yachts, boats, monuments and sculptures.

The comment was sent successfully.