Description and use of foam filler

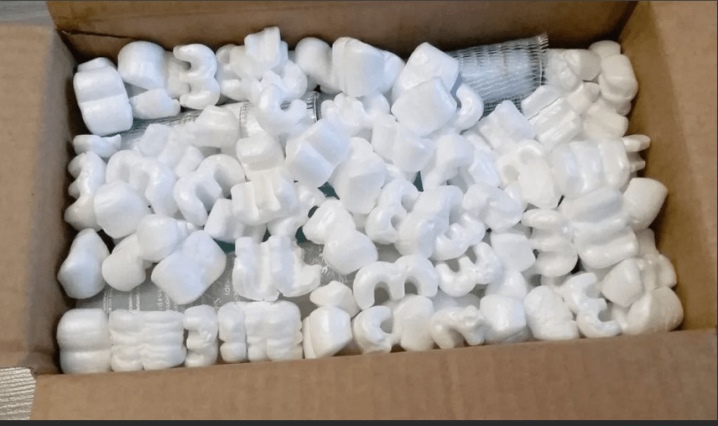

Every person has come across the need to pack fragile items for storage or shipment. Some people use foam filler as a shock-absorbing agent. And where else they find application for it - we will tell in the article.

Advantages and disadvantages

The advantages of free-flowing foam products include their environmental friendliness, density, elasticity, strength, durability. The material can bear a lot of weight. When shrinking, you can add filler to the required volume.

Polyfoam perfectly resists mechanical stress. It is a suitable option for packing porcelain, crystal and glassware, spare parts, electrical appliances, as well as other fragile items that require increased attention to maintaining the quality of the item. Amortization of the filler eliminates the possibility of product splitting during transportation.

The peculiar shape of the product allows you to fix objects, so they do not wrinkle or break.

The material does not deform due to temperature changes. The volume of polystyrene does not change when precipitation hits. The product does not expand or deflate during changes in weather conditions, does not absorb moisture when exposed to water. Polyfoam does not serve as a breeding ground for the reproduction of pathogenic bacteria, fungus, mold. It is flame retardant, does not support self-combustion.

Foam filler is 5 times lighter than air-bubble packaging, and 10 times lighter than paper. A liter contains only 5 g of granules. A lightweight product has almost no effect on the weight of the shipped goods, therefore it is often used for transportation by various delivery services. The material is suitable for repeated use, as it does not lose its properties at all. Its service life is at least 100 years.

Non-toxic foam is completely harmless to human health. It does not electrify and does not stick to the packaged product, does not break, crumbles, does not turn into dust and debris. The material does not absorb unpleasant odors, therefore it is ideal for use in a variety of purposes by pet owners.

The disadvantages of foam include its solubility on contact with chlorinated hydrocarbons, acetone and other esters.

Selection Tips

A quality product is always certified, therefore, when purchasing a product, carefully study the certificate. W-shaped packing filler is generally of high quality. It is great for transporting baby goods and medicines.

The round filler does not move and fixes well the items in the package. Granules have a complex shape, due to which they acquire shock-absorbing properties. The denser the ball, the longer it lasts. Its density should be from 10 to 15 g / l, and its diameter should be from 1 to 4 mm. The larger the granule, the more air it contains.

There is an extruded polystyrene foam core. It has excellent thermal and sound insulation properties. Cubes with a size of 1.5x1.5x3 cm are most often produced from a rigid material of a homogeneous structure. The extrusion technology provides for the tight adjoining of the cells to each other. Thanks to this, the material does not absorb water at all, therefore it is excellent for filling drainage trenches.

The features of the filler lead to the fact that wells and trenches do not freeze in winter.

Applications

Foam filler is used to fill any voids for the purpose of insulation, insulation, drainage and packaging. It can be used to store medicines, precision instruments and any other instruments. Small granules are used for toys and pillows to relieve stress. Extruded Styrofoam styrofoam cubes are ideal for drainage.

Bulk foam is often used for packaging. They fill the free space in the box in order to fix the item being sent. The filler perfectly retains the product in any shake. The granules adhere to each other and do not allow the things in the package to deform. Bulk goods are great for parcels. The packaging filler is very easy to use. It should be poured into the bottom of the box. After placing the goods there, it is necessary to fill in the formed voids with foam plastic and fill the object from above. Even during long-term transportation, nothing will happen to the parcel.

The sent goods will reach the addressee safe and sound.

W-shaped foam effectively protects the load from any vibration, therefore it is excellent for filling boxes intended for transporting and storing any items. It is also used as a decorative material in the manufacture of New Year's toys, as well as insulation.

Foam filler is well suited for making frameless furniture. Ottomans for feet in the form of a tablet or chair, filled with foam balls, adjust to the human body, taking on the shape of the body. Thanks to this, the person relaxes. With any movement of it, a massaging effect is created. The absence of a rigid frame, sharp corners eliminates the likelihood of injury.

The simplicity of the design allows you to make your own pear chair or bean bag chair. First, a nylon cover with a zipper is sewn. Then it is filled with loose packing in the form of foam balls. Rodents and insects are not able to harm the foam, so the chair can be used in the country and in open areas. Light furniture can be easily moved by any child.

The comment was sent successfully.