Making an ozonizer with your own hands

Ozonizers are used to produce ozone from free oxygen in the air. Industrial ozonizers do not always have the declared efficiency, moreover, they are combined with ionizers, taking on the functions of an air purifier from dust. The device must first of all perform in full the main function that is assigned to it. Making a device with your own hands can significantly reduce your costs.

The simplest structural diagram

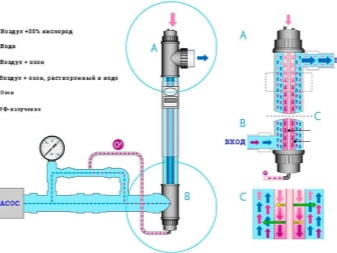

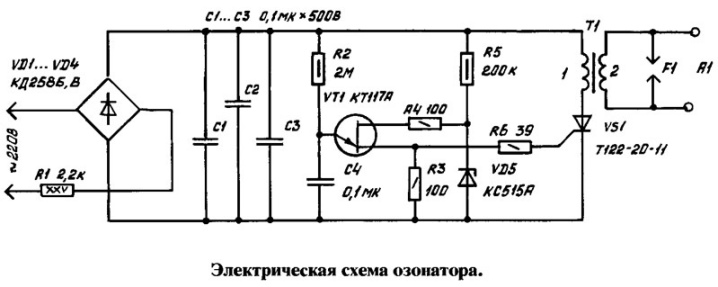

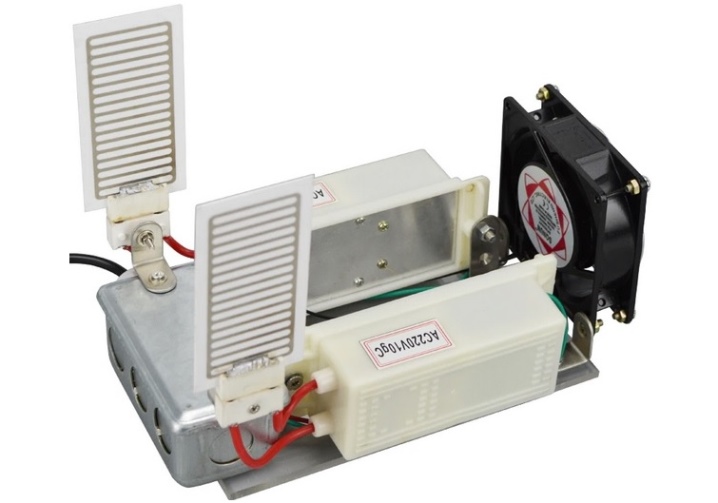

In the simplest case, the ozonizer is a high voltage generator, the output grids of which are blown by a separate fan. A fuse must be included in the circuit to protect the network and wire from damage due to a short circuit. The device consumes much less energy, for example, electric stoves, which means that a 0.5 or 1 amp fuse will come off completely.

Grid (or contour) - strip line on a ceramic dielectric, weakly glowing with a small corona discharge, ionizing and ozonizing the air. The fan allows this circuit (and the generator board) to cool - correctly, without disrupting technology.

The assembled device is capable of operating over a long period of time.

The principle of operation of the device

For the production of ozone, not the highest voltage is needed - only a few kilovolts. It is not a problem to get tens of kilovolts or even 100 kV, but ozonation will be accompanied by a strong corona discharge., which is unacceptable in a domestic environment - it can cause the device to ignite and fire.

Ready modules

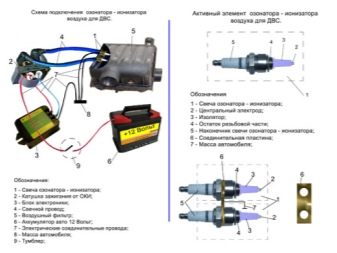

The simplest board costs about $ 5. The emitter itself can be connected to high-voltage wires with high-strength electrical insulation. The optimum throughput of the device is up to 200 mg of pure ozone per hour. Various high-voltage boards are designed for power supply from 5 or 12 V (without a power supply unit), which allows ozonizing the air in a car or a closed tent from an external PowerBank battery.

The pulse converter itself, when converting low voltage to kilovolts, consumes from 8 watts of power.

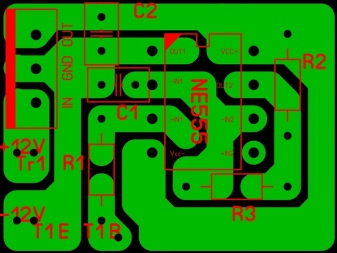

Homemade converter

AC mains voltage can be converted to high voltage by using an automobile ignition coil as a step-up transformer. A converter with a mains rectifier is placed in front of it, which converts the current frequency from 50-60 Hz, say, to 25 kHz - as in a mobile phone charger. If it were not for the generator of high (supersonic) frequency, the dimensions of the device would have become impressive and heavy, like the built-in power supply unit of a Soviet tape recorder.

Assembling the emitter

If it was not possible to get a ceramic insulator, it will be replaced by ordinary window glass. You can also use textolite, from which the current-carrying tracks of the old printed circuit board were removed with the help of a powerful soldering iron. You need to do the following operations.

- Cut two fiberglass plates with a thickness of at least 3 mm and dimensions of 10x10 cm.

- Lay and secure an 8x8 cm aluminum plate on one of these pieces. Do the same with the other aluminum and fiberglass blanks.

- Next, attach a piece of glass of the same size to this plate. Glass thickness - at least 2 mm.

- Fasten the entire "sandwich" with external staples, placing them as far away from live parts as possible.And also adapt it to fit inside the case by installing screw posts or plastic tensioners.

A wider gap (over 2.5 mm) will result in no discharge. A narrow one will lead to the fact that the glass, on the contrary, will soon be burned out, and this is already a punctured dielectric, which is not recommended to be used.

Time limit

A timer is set in industrial ozonizers. For example, you turn on a two-hour session and leave the room, taking your pets (if any) with you. If the homemade device does not have a timer circuit, use an outlet with a timer or time relay function.

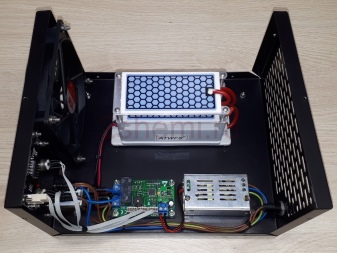

Assembling the main structure

Assembling the ozonizer with your own hands, the components are placed, for example, in a liter plastic container from honey. To supply air and release ozone, 10-20 holes with a diameter of several millimeters are drilled (or melted using a metal tube) in the side walls of the container.

The generator board (ready-made or prefabricated) and the terminal block are placed on the bottom of the can. The mains (or low-voltage) wires with a cross-section of at least 2x0.75 mm (SHVVP mains wire) are connected to the terminal block. A block insert for fuses is installed between the terminal block and the generator. It is unacceptable to solder the fuse in a suspended way - the wires may shift, and the fuse may be disconnected from the network at a dangerous moment. The insert makes it easy to change this fuse. Also, a mini-switch can be mounted separately in the side wall or in the screw-off lid of the container.

If the ozonizer is going to a voltage of 5 or 12 volts, a simple computer fan will come off from the "system unit" power supply. It is attached to the container lid - additional holes can be drilled for it through which air from the room will be sucked in. It will come out (with ozone) through the remaining holes drilled on the sides and in the bottom. The fan can also be powered via an old smartphone charger.

Place the step-up coil or transformer as far as possible from the power cord and generator board. The ozonation circuit should be placed in the center of the structure. To do this, it is suspended on its own wires (ready-made) or by screw inserts (self-assembled). The insulation of the wires must have the required electrical strength to prevent sudden breakdown and discharge of the discharge "to the side". So, a silicone dielectric has proven itself well.

Safety engineering

Leaving the room when the concentration is exceeded up to 0.2 mg / m3 is vital: in small amounts ozone is useful, when the maximum permissible concentration is exceeded, it begins to harm, and with a further increase in concentration it becomes life-threatening. Lethal doses of ozone are used to remove cockroaches, bedbugs, ants, rats and mice from the premises, contactless disinfection of furniture surfaces and other objects in a room or house.

At a significant concentration, the air in the room acquires a bluish-purple hue. - you cannot enter such a room to turn off the device without a gas mask or long ventilation. If you leave the device on and leave for a few days, then your home will be disinfected without using any chemicals. The house or apartment will become as clean as an operating room. Under no circumstances should you carry out such executions - in your absence anything can happen to the device. In addition, if you have not equipped the device, for example, with a controlled IP socket with a built-in 4G module, you will not be able to turn it off on your own until it issues a short circuit.

If the air saturation with ozone exceeds the MPC value by several times or more, the body will die from hyperoxygenation. Fortunately, having felt the smell of ozone already at a concentration of 10-20 μg / m3, the person hurriedly leaves the room. At an altitude of 15-35 km from the Earth's surface, the air is absolutely sterile - the concentration of ozone there exceeds the MPC by a factor of thousands or more. Such a concentration can be created using industrial ozonizers designed for production workshops of hundreds and thousands of square meters, where the production technology requires complete disinfection.

For example, when pasteurizing any semi-finished food, cleaning wastewater from microbes by ozone aeration, and so on.

To learn how to make a powerful air ozonizer with your own hands, see the next video.

The comment was sent successfully.