All about blind area membranes

The blind area serves as a reliable protection of the foundation from various adverse influences, including excessive moisture, ultraviolet radiation, and sudden temperature changes. Previously, the most popular option for creating a blind area was concrete. But nowadays, a special membrane has begun to gain more and more popularity.

Advantages and disadvantages

A membrane for forming a blind area around residential buildings has a number of important advantages. Let's highlight some of them.

-

Durability. Protective structures made of a membrane can last more than 50-60 years without breakage and deformation. At the same time, they can be operated in the most severe conditions.

-

Moisture resistance. Such blind areas can easily withstand constant exposure to water and at the same time will not lose their qualities and reliability. In addition, they can easily withstand exposure to alkaline compounds and acids.

-

Biological stability. The roots of shrubs, trees and grasses generally avoid contact with such protective materials.

-

Simple installation technology. Almost any person can install such a blind area around the building; there will be no need to seek help from professionals.

-

Availability. Membrane materials are created from such simple components as sand, pipes, textiles, gravel.

-

The possibility of dismantling. If necessary, the membrane blind area can be easily disassembled by yourself.

-

Resistant to temperature extremes. Even in severe frosts, the membrane will not lose its qualities and will not deform.

Such products for the protection of foundations have practically no drawbacks. It can only be noted that the installation of such a blind area presupposes the presence of a multilayer structure, since, in addition to the membrane itself, special materials will also be needed to provide additional waterproofing, geotextiles, and drainage.

Views

Today, manufacturers produce a huge variety of such membranes for the construction of a blind area. Let's consider separately each of the varieties, and also highlight their main features.

-

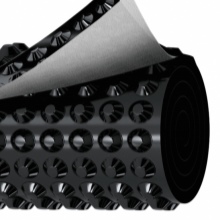

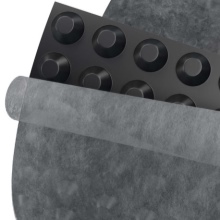

Profiled membrane. This protective material is made from high-quality high-density polyethylene. This base will not allow moisture to pass through at all. In addition, it easily reacts to stretching, easily returns to its original position without deformations and defects. Profiled products are often perceived as complete drainage systems. Such waterproofing membranes are externally rolled up materials that have small circular protrusions. They are necessary to remove moisture from the foundations. This type is distinguished by its maximum service life, it is practically not exposed to mechanical stress, it retains all its filtering characteristics even after a long time.

-

Smooth. These varieties also provide excellent waterproofing properties. They are used to create a good vapor barrier. Smooth models are considered an anti-corrosion material with good mechanical properties, which has a high rate of elasticity and flexibility. In addition, products of this type are maximally resistant to insects, rodents, harmful bacteria and root systems of grass and shrubs.

-

Textured. Such protective membranes differ from other types in their surface structure, which provides maximum adhesion to various types of substrates. The perforated part helps to create the necessary friction. These types of membranes have increased elasticity, they are resistant to low and high temperatures, moisture, ultraviolet radiation. Textured models will not deform or crack even after a long time.

Geomembranes can vary depending on the manufacturing technology and the raw materials used. So, all of them are made from high quality polyethylene of increased density and low or high pressure. Sometimes this material is made on the basis of PVC. If the base is made of low pressure polyethylene, then it will be distinguished by high hardness, strength and durability. The geomembrane is sufficiently resistant to the effects of alkaline compounds, acids, and water.

It will easily withstand even excessive mechanical action, but at the same time it does not have a sufficient degree of elasticity and resistance to deformation. In frost conditions, the material loses its strength, but it easily tolerates high temperature conditions.

Models made of high pressure polyethylene are soft, lightweight and have good elasticity. The material has good resistance to stretching and deformation. The membrane does not allow vapor and liquid to pass through, therefore it provides good waterproofing. Due to their special ability to retain vapors and liquids, such products are used to ensure the isolation of various toxic components. Durable three-layer membranes are made from PVC, which are more often used in the arrangement of the roof, but sometimes they are also taken for the construction of the blind area. These models are distinguished by excellent resistance to ultraviolet radiation, moisture, temperature changes.

How to choose?

Before purchasing a membrane to create a blind area, you should pay attention to several selection criteria. Be sure to take into account the features of the device and installation. So, if you have to work with complex structural elements, then preference should be given to models made of high-pressure polyethylene, because they stretch much better, without losing their important properties and do not deform.

Look also at the cost of the insulating material. High pressure diaphragms are considered more expensive. But for small structures, such products with a lower thickness are often used, which makes it possible to compensate for the difference in cost.

Manufacturers

Today in the modern market there are a considerable number of manufacturing companies producing geomembranes. Let's take a look at some of the most popular brands.

-

TECHNONICOL. This company sells a membrane that is particularly durable, it can last for several decades. Such products for the protection and insulation of the foundation are produced in rolls 1 or 2 m wide, the length of the web can be 10, 15 or 20 m. Together with such roll products, the manufacturer also sells the components that are necessary for their installation. These are one-sided and double-sided tapes for sealing, made on a bitumen-polymer basis, special clamping strips, plastic disc fasteners.

-

"TechPolymer". The manufacturer produces three types of geomembranes, including a smooth one, which is completely impermeable. It provides reliable protection not only against water, but also against hazardous chemicals. The company also produces a special composite Geofilm. It is most often used for additional protection of the membrane itself.

-

GeoSM. The company specializes in the production of membranes that provide waterproofing, thermal insulation, protection from physical influences, aggressive chemicals.The range of products also includes PVC models, they are more often used if it is necessary to create a good vapor barrier. Such products will not need additional protection, they are able to completely isolate the foundation from negative environmental influences.

Mounting

It is quite possible to build a blind area from a membrane on your own, but at the same time it is worthwhile to correctly follow the entire installation technology. The principle of forming the blind area is quite simple. Before starting construction work, you should decide on the type of future protective structure. It can be either soft or hard, they also differ in the type of finish coating. In the first case, gravel is used as the top coating, in the second - tiles or paving stones.

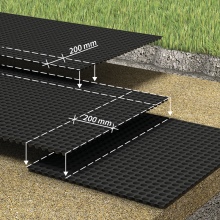

To begin with, you will also need to decide on the depth and width of the blind area for the house. These parameters will depend on many features, including the type of structure, groundwater.

After that, a layer of sand is laid. Several layers should be laid out at once, the thickness of each of them should be at least 7-10 centimeters. Moreover, each of them must be moistened and tamped.

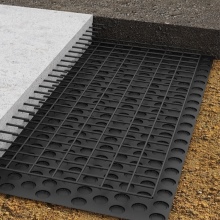

Then the insulation material is installed. Insulation boards are mounted directly on the sand cushion, observing the slope from the building. Later, a drainage layer is laid on all this. For this, it is better to use a special drainage membrane.

The surface of such an insulating material consists of protrusions to which a layer of special thermally bonded geotextile is attached. Through the channels that are formed after laying due to such embossed surfaces, all excess water will immediately flow away and not linger near the foundation.

The geotextile will act as a filter that will trap fine sand particles. When all the layers are laid, you can proceed to the finishing installation. For this, the membrane material is rolled out and laid with the spikes upwards. Moreover, all this is done with an overlap. Fixation is most often done with plastic special fasteners. At the end, gravel, lawn or tiles are laid on the resulting structure.

The comment was sent successfully.