All about polystyrene

Various types of plastic have radically changed our understanding of everyday life - today our life is no longer possible to imagine without certain plastic things. However, there are different types of plastic, and each of its varieties has its own specific characteristics that determine the use of a particular substance in certain areas. Since polystyrene is one of the most popular plastic options today, it is worth considering its features more closely.

What is this material?

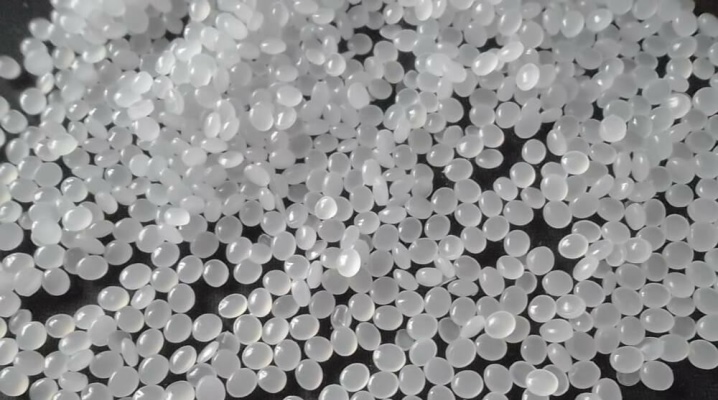

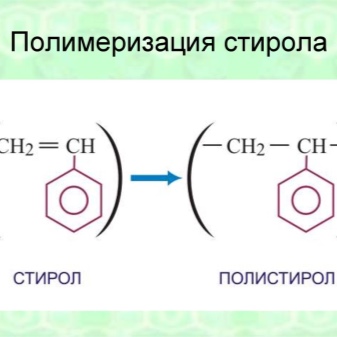

Polystyrene is polymerized styrene, that is, it is a product of the chemical industry. You can achieve its manufacture using various methods, each of which has its own advantages and disadvantages, and we will consider the most popular in more detail in this article below. Wherein polystyrene contains only molecules of such common substances as carbon and hydrogen, but it is made from liquid styrene, which, in turn, is obtained from oil and coal.

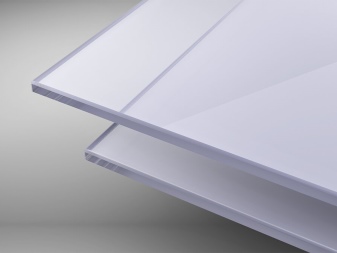

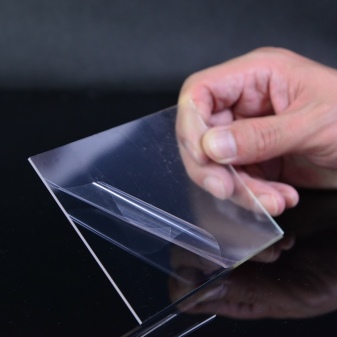

Polymerized styrene looks like a hard and elastic, colorless and even transparent substance that can bend without breaking, and is highly hygroscopic.

For the first time, polystyrene was obtained at the early stages of the industrial revolution - it is known that in 1839 it was synthesized in Germany... Another thing is that its production on an industrial scale began much later - only in 1920, and even then in the first decades it was not used so actively. Only during the Second World War in the States they really became interested in them, producing artificial rubber based on polystyrene, and in the USSR the industrial production of this material was completely postponed until the post-war years.

It cannot be said that modern polystyrene fully corresponds to the samples of a century ago. - during all this time, scientists have been looking for ways to improve the properties of the material. Thanks to this, plastic after the Second World War became much more durable, including much better withstanding impacts - this became possible thanks to the creation of styrene copolymers obtained through even more complex chemical processes.

Properties

Exact the physical characteristics of modern polystyrene are highly dependent on how it was produced, but in general, when we talk about simple polystyrene without any clarification, we mean a material with very specific parameters. Its density is not the highest (1060 kg / m

Molecular mass the substance is also by no means specific and strongly depends on the method of obtaining polystyrene - it usually ranges from 50 thousand to 300 thousand, although emulsion variants sometimes demonstrate significantly higher rates. Solubility polystyrene is significant in a number of substances, including its own monomer, as well as acetone, aromatic hydrocarbons and esters.

It does not lend itself to a number of solvents, including ethers, lower alcohols, phenols and aliphatic hydrocarbons.

Polystyrene has pronounced dielectric propertiesthat do not change regardless of the environment. This material is also practically indifferent to the destructive effects of acids and alkalis, salts, alcohols. Above, we have already listed the substances that can still dissolve it, and it also oxidizes, halogenated, nitrated and sulfonated.

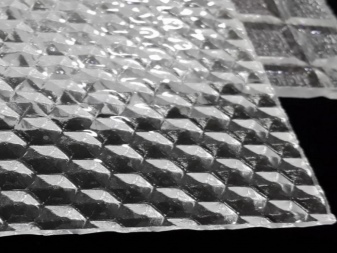

In its original form, without additional tinting, polystyrene (at least its block variety) is not only colorless, but also transparent... The structure practically does not retain visible light, passing 90% of its amount, and this allows the use of such a material in the manufacture of optical glasses. At the same time, ultraviolet and infrared radiation does not pass through polystyrene surfaces so confidently.

If we consider the properties of polystyrene as the advantages that make it so popular in various fields, first of all, it is worth highlighting the following important points.

- Combination of low cost and ease of processing... At its price, polystyrene can be considered one of the main engines of modern civilization, given its properties. It is not for nothing that today so many products are produced with the direct participation of this material - it simply does not really have an alternative.

- Good chemical resistance. Most of the substances that can get on a polystyrene surface in everyday life do not pose any danger to it - this is great news for manufacturers who want to produce products that are distinguished by durability. At the same time, in a chemical laboratory, having an impressive set of reagents at hand, it is not difficult to dissolve polystyrene.

- The toxicity is relatively safe. Polystyrene emits relatively little of any harmful fumes and from an environmental point of view, with certain reservations, is considered harmless. At least, experts do not put forward any restrictions on the use of polystyrene materials inside residential premises, and even polystyrene dishes can be made.

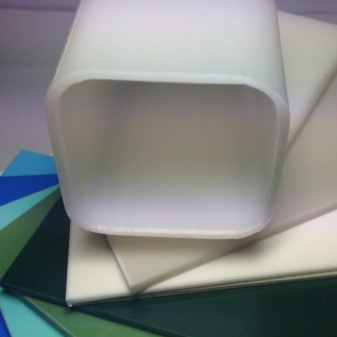

- Wide range of applications... Due to its qualities, ease of processing and dyeing, polystyrene can be used as a raw material for the production of anything.

With all the advantages of polystyrene, it also has limitations, and although there are not many of them, sometimes they play a very significant role.

First of all, any overheating for such plastic is dangerous, and even in domestic conditions you still need to think about where you can use polystyrene and where you shouldn't. In addition, for most types of material, in addition to shock-resistant, impacts pose a significant danger, and in general, general fragility is a problem.

Comparison with polypropylene

One of the main competitors of polystyrene is another popular polymer - polypropylene... In some areas, such as the production of packaging materials, they are direct competitors, but the difference between the two materials is quite significant. It's worth starting at least with the fact that polystyrene is difficult to recycle, and although you can often hear that it is safe, environmentalists still love to find fault with it.

Polypropylene is also not without sin, but there are still a little fewer questions about it, and it is easier to recycle it. If we talk purely about the physical qualities of the two materials, then polypropylene is also characterized by increased flexibility - where polystyrene is already breaking or cracking, malleable polypropylene simply bends. As for the price, polystyrene, perhaps, would have lost the competition to its rival long ago, but more low cost Is the factor that keeps it afloat so far.

Visually distinguishing one from the other is not so difficult, but you need to know what to look at. Polystyrene looks more beautiful it is glossy and shiny, without additional coloring it looks transparent, although it can have a characteristic cold shade of blue. Polypropylene seems a little dirtier due to its haze., the light scattering effect is much higher. You can also distinguish between two materials by tapping: polystyrene is resonant and emits characteristic clicks when struck, while polypropylene sounds muffled.

Is it harmful to humans?

Polystyrene is one of the most controversial materials in terms of assessing harm and danger to health. On the one hand, it is used extensively in human dwellings and even for the manufacture of dishes, which already suggests that this is not prohibited. On the other hand, numerous statements calling into question the environmental friendliness of plastic refer primarily to polystyrene. It will be fair to say that, while not being the most dangerous of the existing materials, it still cannot be considered safe either - it could not be used so actively.

It should be understood that styrene, which is a raw material for the production of polystyrene, is considered very toxic.

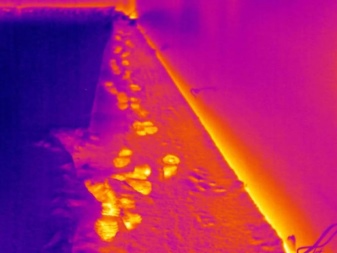

Polystyrene can emit not so many toxic substances that will not affect human health so much, but this is only as long as you are not in constant contact with it, and until it heats up. The higher the temperature, the more dangerous the neighborhood with polystyrene products, especially if a fire has started and the material is on fire. Most of all, chemical fumes disrupt the liver, but problems can even be with the heart and lungs, and some experts believe that the banal inhalation of styrene vapors is fraught with the development of hepatitis.

You must also understand that polystyrene and polystyrene are different: to improve the properties of the plastic, the manufacturer can add various plasticizers, dyes, and other additives that affect the strength and elasticity to the material.

In some cases, these additives may turn out to be even more dangerous than styrene itself, and the manufacturer may not indicate the additional hazard data so as not to lose customers.

When above we called polystyrene relatively safe, we meant that there are other, even more harmful products of human activity, which we still cannot give up - for example, car exhaust. In addition, in theory, polystyrene can be used almost completely safely - provided that you know and strictly follow the instructions, in particular, not by promoting heating of the material, but by protecting it from it. But even so You should not perceive polystyrene as a completely safe substance, because even in the world of plastic, which has received more and more criticism in recent years, polystyrene is not the safest.

Species overview

Presently for the production of polystyrene, several methods of obtaining are used the desired material, and in terms of its properties, the finished result will not always be the same. To understand how it works, Let's take a look at each of the three popular methods.

Each of these materials has a marking with a characteristic designation of the method of obtaining polystyrene.

Emulsion

Today this the method is already largely outdated and is practically not used in production... The principle of operation is as follows: first, styrene is purified from inhibitors, after which it is combined in water with emulsifiers (salts of fatty and sulfonic acids, soap), as well as polymerization initiators - potassium persulfate and hydrogen dioxide. When heated to 85-95 degrees, a chemical reaction occurs - a gradual polymerization process, which is considered complete if the amount of styrene falls below 0.5%.

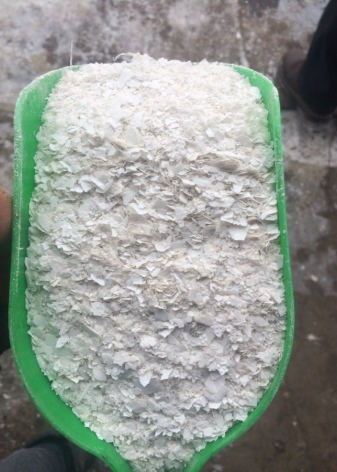

The resulting emulsion is then coagulated with a solution of ordinary table salt and is subject to drying, as a result of which a fine granular powder is formed, each granule of which has a size of no more than 0.1 mm. Although polystyrene is usually described as white and transparent, this method will not be able to achieve these characteristics. - the balls have a yellowish tint, indicating the presence of alkali impurities, which cannot be completely eliminated.

Although the method is unpopular today, it is precisely this method that provides a substance with the highest possible molecular weight.

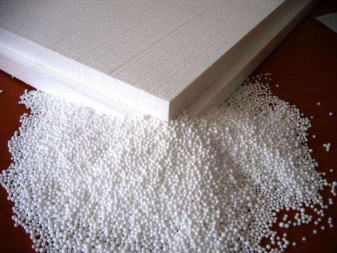

Suspension

Another method that is already considered outdated, although it is still considered suitable for recycling polystyrene into copolymers like expanded polystyrene. For production, you need prepared styrene, or rather, its suspension in water, magnesium hydroxide, polyvinyl alcohol, sodium polymethacrylate and polymerization initiators. All this is sent to the reactor, where the substance is actively mixed with gradual heating up to 130 degrees and high pressure. After that, the resulting suspension still needs to be subjected to centrifuge processing, and only after washing and drying the collected material, polystyrene is obtained.

Blocky

This method is considered the most popular and relevant today, and most of the polystyrene is produced today in this way. The rationale is quite simple: the output is a pure material, ideal in terms of lighting technical parameters, characterized by the stability of the parameters. At the same time, the use of the technology under consideration is both effective and guarantees almost complete absence of production waste.

Block production of polystyrene is based on stirring styrene in a benzene environment in two stages - first at a temperature of about 90 degrees, and then with gradual heating from 100 to 220. Block production is stopped at a stage when about 85% of the styrene mass has turned into polystyrene. Removal of styrene that has not had time to polymerize is carried out using a vacuum.

Application

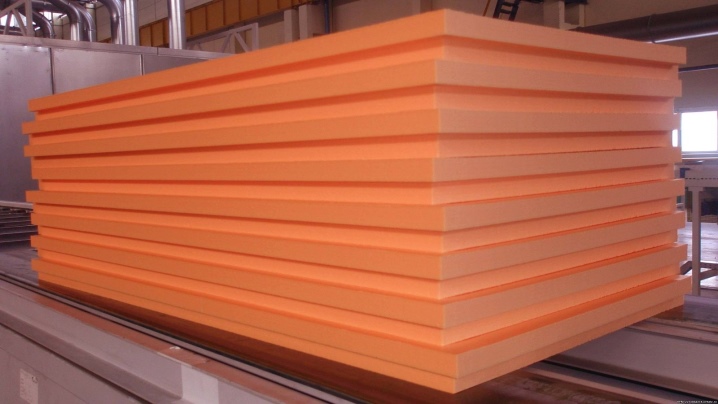

Polystyrene is used in a huge number of areas of human activity and is even used for making crafts with your own hands. At home small souvenirs are made of it, using laser cutting, milling, painting in any colors - from red to gold and black, and in some cases - and printing on a polystyrene surface. The widest application of polystyrene is found in construction, where it is used to make wall panels and ceiling tiles, various partitions and baguettes. In sheet form, this material can also be used for facades. In the end, on the basis of this material, they produce the recently popular polystyrene concrete.

Furniture industry also uses this material more and more actively, although at the moment it is not a competitor for wood and its derivatives. However, where the humidity is high, it is used constantly - for example, a shower tray can be made entirely from it today. In addition, polystyrene granules are used like filler in pillows, and for these purposes are sold ready-made in bags.

To an ordinary person, the food variety of polystyrene is well known as almost the main material. for the manufacture of disposable tableware... Most of the plastic cups that are so popular for bottling soft drinks today are made from it. In addition, food grade polystyrene is heavily used as packing material due to its low cost and relative strength. Considering the dielectric properties of the material, it is worth noting that it has also found wide application in electrical engineering.

At the same time, in fact, there are so many options for using polystyrene products that it is simply not possible to list them all.

How to work with him?

In everyday life, most often you have to work with sheet polystyrene, which can be processed both mechanically and thermally. Forming by bending, gluing, cutting and drilling can be both an ordinary type of material and an impact-resistant one. An ordinary jigsaw is used to fragment a sheet with a thickness of less than 2 mm, while thicker sheets can be taken with a grinder or with a hand tool. In an industrial workshop laser cutting is possible. The cutting line turns out to be a little torn, therefore it requires subsequent processing - it is first passed with a file, and then with emery.

If it is necessary to make a hole in the sheet, use a drill, for which you need a drill created specifically for drilling sheet plastic. If the thickness of the sheet is small, during drilling it may deform against the wishes of the master - you can avoid such a development of events by placing a wooden block under the sheet. The sheet is formed either by a vacuum technique or by blowing air under high pressure. Processing by any of the indicated methods involves significant (up to 160-200 degrees) heating of the material.

The connection of individual parts made of polystyrene is allowed both by welding and by gluing. In both cases, before joining the fragments of the surface, you must first carefully degrease. It is necessary to cook either by gas or ultrasonic method, to glue - with polymer compositions based on cyanoacrylate or neoprene.

If we talk about matte polystyrene, then it can also undergo such a type of processing as grinding and polishing. For this, a grinder is used, but in no case with an abrasive wheel - instead, a soft wheel is taken, on which a special polishing paste is applied. If the part is small, you can also polish or grind it by hand.

Among other things, any special coatings can be applied to the polystyrene surface – from a metal layer to a mirror film. It can be printed on it in black or color, in any of the known ways. At the same time, to protect the resulting text or image, it is necessary to open the surface with varnish, because the polymer does not absorb moisture.

Processing

In its pure form, polystyrene does not seem to do much harm to the environment, but at the same time, its waste, as it should be for plastic, persists for a huge period of time, polluting the planet... In addition, being in the natural environment, the polymer and its copolymers can be exposed to excessive heating, including combustion in a fire, and then the consequences can be much more dire. Likewise, uncontrolled contact of polystyrene objects with substances capable of dissolving the material is undesirable, otherwise the release of toxic vapors of styrene, benzene, toluene, carbon monoxide and ethylbenzene cannot be avoided.

The relative advantage of the material is that it can be recycled in most cases, utilizing both direct waste and simply worn-out products from it. Extrusion, pressing and casting are used as processing techniques. At the exit, products are obtained that are not inferior in quality to new ones, while no garbage is formed. In addition, in recent years, a new building material has been made on the basis of polystyrene - polystyrene concrete, which is appropriate for low-rise construction. Unfortunately, huge amounts of polystyrene waste, especially in poor countries, are simply incinerated. This behavior with plastic waste is extremely negative for the environment.

The next video tells about sheet polystyrene and the features of its application.

The comment was sent successfully.