What is HDF and how is it different from other materials?

Wood building material can be in the form of lumber or wood composite. Composite wood semi-finished products are usually presented in the form of glued wood or a material based on shredded wood. The demanded wood-shaving products include MDF, as well as its kind of HDF.

What it is?

Not everyone knows how HDF stands for. Explanation of the English abbreviation HDF - high density fiberboard... The basis for the manufacture of the sheet is shavings from the woodworking industry. In the manufacture of this material, crops are used that are cut down during the sanitary processing of the forest.

The composition of the HDF panel is a pressed fine fiber in the form of shavings... Thanks to the use of high pressure, significant temperature and the addition of astringent organic substances, durable sheets of environmentally friendly material are produced. In the manufacture of fiberboard, the following steps are performed:

- screening, washing the chips, followed by keeping them in a cooking-type boiler under a pressure of 10 bar;

- mixing wood chips with glue;

- blowing the resulting mixture into a drying tube;

- after reaching the required moisture content, the fiber is transferred to a separator, where it is thoroughly cleaned;

- fiber feeding to the press line;

- trimming edges;

- compaction of the material under the action of a temperature of 240 ° C;

- trimming, weighing and directing the HDF to the refrigerator.

As a result of carrying out all the above measures, hard sheets with good quality characteristics are obtained.

General characteristics

HDF boards are sold with a thickness of 2.5 to 6 mm. The standard dimensions of the sheet are considered to be 2.5 by 2.8 and 2.07 by 2.8 m. The density of this material can be up to 1000 kg / m3. The main advantages of HDF:

- environmental safety and cleanliness;

- increased strength;

- flatness of the surface without deviations;

- wear resistance;

- resistance to aggressive substances;

- durability.

Moisture resistant material lends itself well to all kinds of processing. The use of HDF contributes to good soundproofing of the room. There are practically no downsides to pressed boards.

However, experts highlight their insufficient moisture resistance, which limits the possibility of their use in damp rooms. But this drawback can be corrected by applying a special composition to the entire surface.

Comparison with other materials

Comparing HDF with similar materials, the consumer wants to find out what is the difference between them, and which product is better for a particular task. The difference between fiberboard is that this material is not able to withstand heavy loads. At the same time, the congestion of the HDF will not cause deformation, cracking or fracture.

HDF differs from MDF in that MDF is used for the manufacture of the supporting side of the furniture structure. For this reason, the sheet always has a thickness of 4–5 cm. In this case, HDF, when used for the above purpose, has a thickness of almost 10 times less. Unlike plywood, HDF lends itself well to painting and has a more attractive appearance.

Species overview

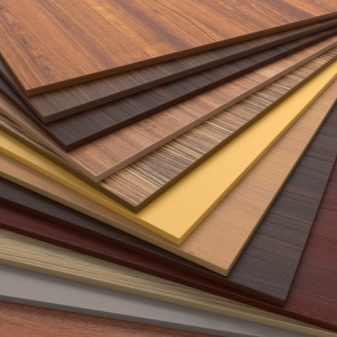

Thanks to modern technologies, the consumer has the opportunity to purchase the material that will satisfy him as much as possible in all respects. HDF is sold in several varieties, namely: polished and decorated.

Sanded on both sides

High-quality material with double-sided grinding is available in 2 classes. Mid-range HDF comes in the form of sheets with one smooth side. The high-end product is characterized by high density and identical surface characteristics. This pressed material is not externally processed.

Decorated

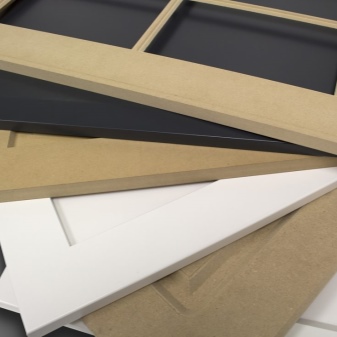

Lacquered boards are made from sanded ones. They are of 2 types.

- Laminated... They do not come on sale often, as they are characterized by low wear resistance.

- Laminated... This product is sold in a wide range of colors and textures.

Decorated boards can be primed and used as an ideal base for making furniture.

Variety of colors

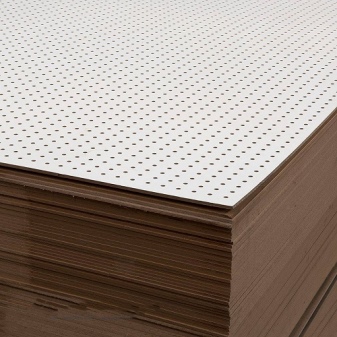

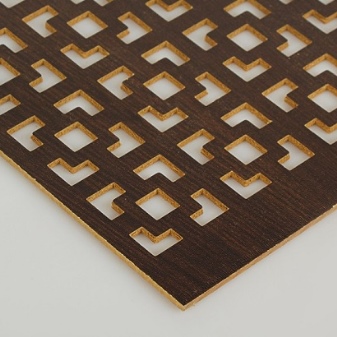

HDF material is characterized by good horizontality, high performance characteristics. Lacquered panels look stylish and attractive, as they can have a variety of colors: they are white, black, gray and other colors. In addition, the HDF surface can be painted in wenge, maple, beech and metallic. Manufacturers sell the following types of perforated color panel sheets: hilt, gloria, veron, city, techno.

Applications

The high density and strength of HDF boards contribute to their use for flooring. Often, subfloors are made from this material. Since the sheets are able to withstand all kinds of mechanical stress and laser cutting, they are used as a basis for laminate or natural veneer. HDF material has found its way into the furniture making process. The affordable cost of the plates allows them to be used for the production of those elements of furniture structures that are hidden under the facade. For example, they are used to make doors, back walls of furniture structures, and the basis for drawers. Also, HDF is often used to make picture frames, trade stands and various decorative elements.

Since HDF sheets have a minimal deviation from the thickness indicator, they are considered an ideal basis for leveling a wall or floor. In non-residential premises, they form a suspended ceiling, with which you can hide the elements of ventilation and communications. In the field of automotive and railroad car building, HDF is a material used to decorate the inner surfaces of a bus or tram. It is difficult for industrial production to do without it in the production of containers and packaging.

Wall panels are produced from HDF boards, which create imitation of stone and tiles. In this case, the material is an excellent option for decorating walls and a kitchen backsplash. Do not forget that HDF partitions will be a great alternative to drywall, and even surpass them in many ways. Such a structure will not vibrate and will retain its strength for a long time.

Often, in office premises and corridors, wall cladding is carried out using HDF sheets. With their help, a vertical fence is installed to the full height and a curb is formed. HDF leaf is an excellent basis for an interior door, as it will have a small mass in comparison with a solid wood door. You can make such doors at home, while not requiring significant material and physical costs, as well as special skills.

How to care?

Wood-based panels require special care. For a long service life of HDF, it is worth listening to the following recommendations:

- keep the surface of the material clean;

- do not use aggressive chemical cleaning agents when wet cleaning the surface;

- do not install heating and heating devices in the immediate vicinity of HDF products;

- do not expose the material to sharp mechanical stress.

Caring for HDF products does not involve any difficulties.They should be wiped with a damp cloth dampened with a mild cleaning agent. It is worth remembering that care measures should be not only correct, but also regular.

The HDF wall panel has not only an aesthetic purpose, but also is able to protect the surface from premature destruction. If you want to buy an inexpensive material for cladding walls, floors or building a door structure, the master should pay attention to HDF sheets. This product does not emit toxic substances and has a European hygiene certificate. When carrying out repairs and other works, experts recommend purchasing HDF sheets, since they are not only cheap, but also have a lot of advantages with almost no disadvantages.

In the next video you will find a short overview of Lamineli HDF panels.

The comment was sent successfully.