Beautiful ventilated porcelain stoneware facades: installation advantages for country houses

Ventilated facades with the use of porcelain stoneware slabs were initially used only for finishing public and administrative buildings. However, the strength and durability of the material, as well as its exquisite and expensive appearance, quickly attracted the attention of owners of private houses. It is not surprising that today country cottages with porcelain stoneware cladding are becoming widespread.

Material features

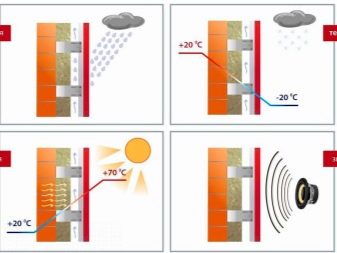

The ventilated facade made of porcelain stoneware serves to protect the walls of the building from negative environmental factors, and also serves as a decorative function. The material is used to organize a hinged facade system, one of the features of which is the fastening of the finishing material to a special crate.

The curtain wall can be ventilated or non-ventilated. The first type is characterized by the presence of air space between the wall and the facade material. The advantages of a ventilated system using porcelain stoneware tiles are to increase the heat and sound insulation performance of the building, its weather resistance, and at the same time its durability.

The use of lathing allows you to hide minor defects and irregularities in the surface to be finished. Finally, thermal insulation material can be installed in the airspace. In this case, an air "cushion" is formed between the outer finishing layer and the insulation layer.

Siding, slabs and porcelain stoneware, which are popular today, are used as facing materials. Let's take a closer look at what this material is.

Porcelain stoneware is a kind of artificial stone. It contains quartz sand, clay, feldspar, as well as dyes and modifiers. The surface of porcelain stoneware imitates the texture of natural stone. The visual similarity of the materials is surprisingly accurate - the layman can only identify an artificial analogue upon close scrutiny.

Unlike natural stone, porcelain stoneware has less weight, easier processing and installation method. It does not require constant maintenance, has a smooth surface that is prone to self-cleaning, and is characterized by the absence of background radiation. Finally, the cost of porcelain stoneware tiles is almost 3 times lower than the cost of a natural analogue.

It is also worth noting such advantages of the facade material as:

- high strength, resistance to environmental influences;

- increased resistance to loads (static and dynamic);

- improved sound insulation values;

- maintainability - the ability to replace only the damaged element without dismantling the entire facade;

- fire safety - the material does not burn, is not prone to spontaneous combustion, does not emit toxic substances during a fire;

- environmental friendliness due to the naturalness of the composition;

- durability.

Compared to other facing materials (except natural stone), porcelain stoneware has a lot of weight. This implies additional strengthening of the building foundation, which means an increase in the labor intensity of the process of construction and installation of slabs, and also entails an increase in financial costs. It should be noted that the cost of the material itself is quite high.

Device

The impressive weight of porcelain stoneware slabs implies the manufacture of a powerful and reliable subsystem. The data sheet for the material recommends using it only on an aluminum base. However, in practice, galvanized counterparts are used to reduce the cost of installation. There is no official data indicating the collapse of facades due to such a replacement, however, it should always be remembered that non-compliance with the manufacturer's recommendations entails additional risks.

The subsystem is used to install porcelain stoneware on it and to ensure that the air gap between the outer skin and the wall is maintained. The subsystem is based on profiles connected horizontally and vertically.

The fixation of porcelain stoneware is usually carried out on clamps, which are mounted in an open or hidden way. The latter method is more laborious and helps to increase the estimate, but aesthetically more attractive. For work, only facade tiles made of porcelain stoneware are used. Despite the apparent strength of the floor counterpart, its use is unacceptable due to the greater thickness of the tiles, and, therefore, greater weight. The thickness of the facade tiles is always the same and amounts to 10 mm.

The subsystem profiles are fastened to the wall using brackets. Insulation (mineral or basalt wool) is also installed between the crate and the wall, and a windproof film is placed on top of it. All accessories and fasteners must be made of stainless steel or have an anti-corrosion coating.

Views

Depending on the method by which the subsystem is cladding, there are 2 types of ventilated porcelain stoneware facades:

- glue system (plates are fixed to the crate with polyurethane glue);

- clamping system (fixing of porcelain stoneware to the subsystem is carried out by means of fastening mechanisms).

A building trimmed with porcelain stoneware can look different. This partly depends on the type of "stone" used.

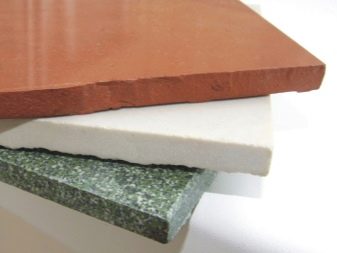

There are the following types of porcelain stoneware slabs:

- matte (the surface is not polished during the manufacturing process, therefore the product is non-shiny, has the lowest cost);

- glossy (it looks more elegant, respectable, the surface does not attract dust, but the smallest cracks and scratches are noticeable on it);

- satin (characterized by a variety of shades and the presence of dark patterns, which is achieved by spraying mineral salt on the surface);

- semi-polished (polishing with compositions with larger fractions, which reduces the cost of the product in comparison with the glossy analogue);

- structural (matte, slightly rough surface with imitation of the texture of natural stone).

Differences may also apply to the dimensions of the slabs. There is no single standard governing the requirements for the dimensions of the material. Usually the slabs are square with sides from 40 to 80 cm. The use of smaller slabs does not look so attractive visually - from a distance, the impression of a finely lined facade is created.

Installation methods

As already mentioned, porcelain stoneware can be connected to the lathing by means of clamps or glued to polyurethane adhesives. In addition to glue, double-sided adhesive tape is used. Its task is to hold the material until the adhesive is completely polymerized.

The mechanical method assumes open and closed types of installation. Open (visible) technology involves the use of an ordinary clamp, the antennae of which are quite noticeable after installation. This is the disadvantage of this method. However, the open type of installation is faster and less labor intensive.

In a closed installation, the porcelain stoneware is fixed with a clamp to the guide profile. Clearly, the cost of the job is increasing, as is the complexity. As a result, the joints between the slabs and the tendrils of the fasteners are invisible, creating the effect of a single stone wall.

The main stages of work

Installation of hinged ventilated porcelain stoneware facades is carried out in several stages. We present an example instruction of action.

- Project creation. At this stage, drawings of the future cladding are drawn up. Examples can be found on the Internet, adapting them to the dimensions and features of a particular house. After drawing up the plan, it becomes clear the required number of plates, profiles for battens, clamps and other fasteners.

- Preparation for work. At this stage, the purchase and delivery of materials to the construction site is carried out. Since the country house is located on a private territory, it is not necessary to fence the place of future work with materials corresponding to the standards and install a warning sign. However, for the sake of your own safety and to prevent accidental damage to materials, it recommends that you somehow designate the place of work.

- Facade preparation. This stage of work, in turn, includes smaller processes: inspection of the facade, removal of protruding elements of the current cladding, strengthening of dilapidated areas, priming of the surface.

Next, the facade is marked with an indication of the installation points of the fasteners. To work you will need a level, tape measure and paint (it is preferable to chalk).

It is important that the markup is carried out exactly with the project documentation.

- Installation of brackets. The quality of fixing porcelain stoneware depends on the accuracy and reliability of the brackets. Holes are made under the bracket on the facade, the diameter of which is 5 mm less than the diameter of the hardware. Before installing the brackets, a paronite (compensation) insert is laid between them and the wall.

- Insulation fixation. Basalt insulation in the form of slabs is usually used. It is enclosed between the brackets and fixed with foam glue or dowels. It is necessary to start laying the insulating sheets from below; it is recommended to put them on the basement or starting profile.

The latter prevents the insulation from slipping, and also protects it from rodents. Each subsequent row of insulating material is laid with an offset of ½ sheet.

- Membrane assembly. A windproof film (or its improved version - a diffusion membrane) is designed to protect thermal insulation sheets from air currents that penetrate into the space under the facade through ventilation gaps. The film covers the entire facade and is overlapped. After its installation on top of the film, breaking through the insulation, dowels-umbrellas are installed. Thanks to this, it is possible to hold the materials together and ensure their reliable fixation.

- Installation of profiles. It is produced in accordance with the manufacturer's recommendations for the type of assembly of the children's designer - first, the supporting elements are installed and fastened, then all the rest.

- Installation of porcelain stoneware. If the boards are glued to the profiles, then the manufacturer's instructions must be followed, which are usually given on the adhesive packaging. When fixing on the clamps in accordance with the design documents, the location of the fasteners on the T-profile should be determined. Make holes for fasteners with a drill, and then attach the clamp with rivets. Now you can install a facade slab on it.

When performing concealed installation, cuts are made at the ends of porcelain stoneware, at least 4. These holes are connected with fasteners. This technology allows you to hide the clamps, as well as evenly distribute the weight of the slab on the frame.

Correction of possible errors

In order for the operation of the facade to be pleasant and long-term, it is important to avoid common mistakes.

- Installation of the subsystem at a negative temperature, which leads to the weakening of fasteners, loss of strength of the subsystem.

- The refusal of a compensating pad when installing the brackets causes their gradual weakening due to the compression and expansion of the material with temperature fluctuations.

- When installing insulation in several layers, the seams of the heat-insulating sheets coincide, which can result in a decrease in the thermal efficiency of the facade due to the formation of cold bridges.

- Excessively close clamping of the clamps, due to which the porcelain stoneware fits too tightly into the fasteners. When heated, this causes an increase in the internal stress of the system and an increase in the size of the slab. This may even become the reason for her rupture.

Design solutions

The ventilated porcelain stoneware facade system always looks elegant and respectable. It is best suited for large houses.

When choosing a shade of slabs, beige or gray slabs will be a win-win option. Stripes made of material of a contrasting or just another shade will help to avoid monotony.

Glossy panels are effectively combined with large mirrored windows. Moreover, each of the elements emphasizes the attractiveness of the "partner". The building looks spacious, "status".

The theme of shiny glazed surfaces can be expanded by combining glittering porcelain stoneware slabs with façade glazing.

Plates look harmoniously both on walls that are quite simple in configuration, and on complex ones. The combination of slabs of different shades or textures allows to emphasize the sophistication of architectural forms.

How the ventilated facade is clad with porcelain stoneware, see the next video.

The comment was sent successfully.