Formwork around the house

Building your own home is a complex and painstaking process that usually involves the whole family. It all starts with choosing a location and drawing up a drawing, and ends with the installation of formwork around the foundation. It is the last step that raises many questions for novice builders. Before proceeding with it, you need to decide on the material and type of blind area, and then study the step-by-step instructions for making this element.

What is it and why is it needed?

The formwork (blind area) around the building is a wide strip that runs along the entire perimeter of the foundation. It performs several functions at once.

- Eliminates the ingress of moisture on the foundation. Many people consider the installation of formwork stupid and a waste of money, but by skipping this step, the builder will spend a lot of money to replace the foundation. The fact is that at the beginning of spring and in the middle of autumn, as a result of heavy rains, the structure will begin to erode, so that after a while nothing will remain of the foundation.

- Improves the appearance of the building. Agree, formwork can be great to decorate a gray and nondescript house, or it can be an addition to a bright design.

- Strengthens the thermal insulation of the house. An additional layer of concrete or other material will never be superfluous. On the contrary, it will help you save on heating bills.

- Interferes with the life of plants. Their root system is unable to develop without oxygen, which is why the plants weaken and do not destroy the foundation of the building.

Therefore, a properly made formwork is a guarantee of a long service life of the foundation.

You cannot do without it in almost any construction, with the exception of houses standing on a pile-screw foundation. There are certain GOST standards, which indicate the main nuances of using the blind area: the purpose of use and standard sizes.

The blind area is a structure that is installed in order to protect the structure from the flow of water. The base of the formwork is usually covered with concrete or porcelain stoneware tiles to not only protect the ground from water ingress, but also to improve the appearance of the building. Another formwork design option - use of clinker bricks.

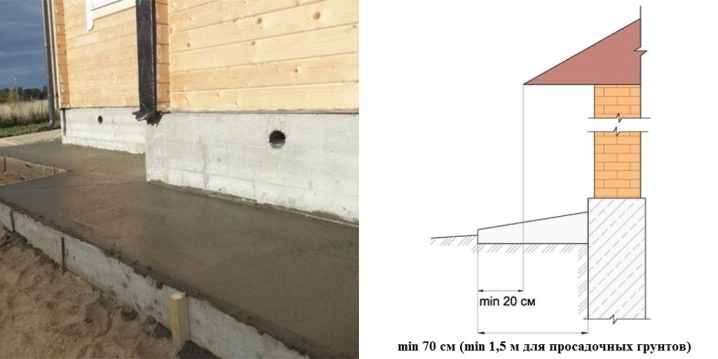

Many indicators affect the size of the blind area, and its scheme is drawn up depending on the type of soil and the width of the roof projection. This design can be 70 or 100 cm - these are the minimum dimensions from which you need to make a start.

In looser (subsiding) soil, the width of the structure should be at least 1.5-2 meters.

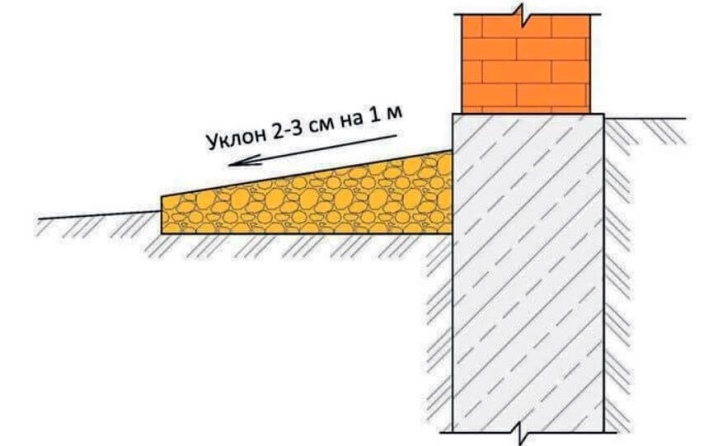

If the ebb system in a one-story building has not been planned, the width of the formwork should go beyond its projection by 30-35 cm.If a foundation pit was made for the construction of the house, the width of the formwork increases: it should extend beyond its limits by at least 45 cm. The angle of inclination of the blind area, according to GOST standards, can vary from 1 to 10%, and for loose soil - from 3 to 10%.

Description of species

There are two main types of formwork: removable and non-removable.

Detachable

As it is easy to guess from the name, removable formwork is removed after construction, while non-removable formwork remains permanently and serves as an additional guarantee of the strength of the foundation. There are not so many advantages of removable formwork, but the most important thing is its cheapness.This structure can be reused, which is especially attractive for commercial organizations that build a large number of buildings and can use the same structure dozens of times.

The main requirement for formwork panels will be strength sufficient to withstand the pressure of the concrete. The inner surface of the shields must be leveled. Metal models are considered the most durable, but they are very expensive to operate (even though they can be rented). There are also expanded polystyrene formwork. But even this variety of materials does not make removable formwork more popular than non-removable.

Non-removable

The advantages of fixed formwork are much greater: it increases the strength of the foundation, improves thermal insulation, and speeds up the construction process. Even people without experience can work with it, without worrying that some problems will arise. The price is slightly higher than that of the previous version, and depends on what materials are used as a basis.

The most modern of all materials used - polystyrene... It has a number of significant advantages: easy to install, high-quality waterproofing and insulation of the foundation. The disadvantages include the high price. Formwork made of metal... Used steel sheets with a thickness of 1-2 mm. They are durable and versatile. In addition, the device can be additionally reinforced with reinforcement.

Reinforced concrete blind area is created from ready-made slabs, due to which it is possible to reduce the consumption of concrete without sacrificing the quality of construction. The advantages include strength, the disadvantages are the high cost and the need to attract special equipment in order to install the structure.

Wooden blind areas remain the most popular type due to low cost, ease of installation and availability of material. Cons: during installation, fastening materials will be required, which increases the cost of the structure. Also, we must not forget that the tree is easily rotting.

Therefore, wooden structures are advised to be used in the construction of light buildings, the construction of the foundation of which is planned as soon as possible.

However, this is not the entire list of materials. Depending on the desires and capabilities of the builders, you can apply slate (smooth) or corrugated board. Such materials are chosen because of their cheapness and availability, but they also have quite a few disadvantages. It will be very difficult to assemble a structure from slate and similar materials; you will have to seek help from professionals, and this is an extra cost. The quality of the resulting load-bearing structures is very doubtful; when concrete is poured, its leaks almost always take place. This is a last resort option.

Selection of materials and tools

The material is chosen depending on financial capabilities, based on the size and purpose of the future building.

Poor-quality material will have a detrimental effect on the final construction site and on the durability of the entire building, so it is better not to save on the blind area.

Also, to install the structure, you will need a number of tools, without which installation is impossible:

- shovel (for trench preparation);

- measuring instruments (tape measure, level);

- Master OK;

- saw;

- putty knife;

- hammer and nails;

- material that will be used to strengthen the trench (for example, fine and medium crushed stone, sand);

- formwork materials (cement and boards).

It is also desirable to have a wheelbarrow on the farm: it will greatly facilitate the work of moving goods.

How to do it yourself?

Before starting the first stage of construction, it is necessary to decide on the material and type of construction. Only then can you start marking. To do this, a projection is created from the edge of the building, to which 30 cm is added. Focusing on this marking, it is necessary to remove the top layer of soil (the depth is approximately 25-30 cm).

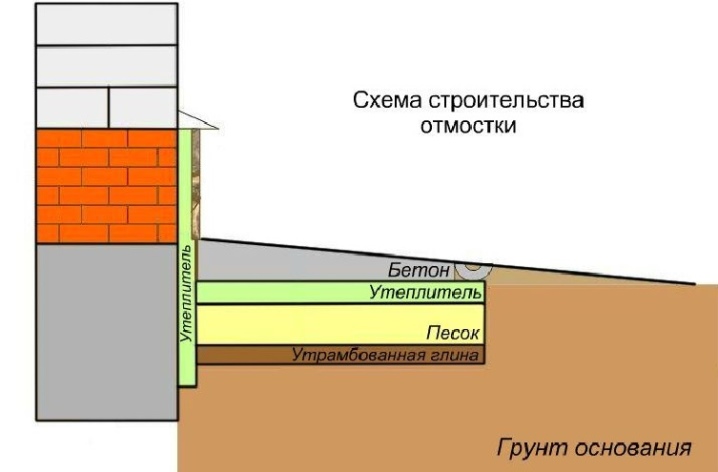

The bottom of the resulting trench must be carefully tamp... It is advisable to put crushed stone as the lowest layer. The middle fraction of crushed stone (from 40 to 60 mm) is used as the main one. It is poured, leveled and tamped, after which it is necessary to additionally fill in fine crushed stone (from 5 to 15 mm). Thus, the voids between the particles of crushed stone of a larger fraction are filled. The crushed stone layer is compacted by pouring water. The next layer is sandy. It should also be tamped with water.

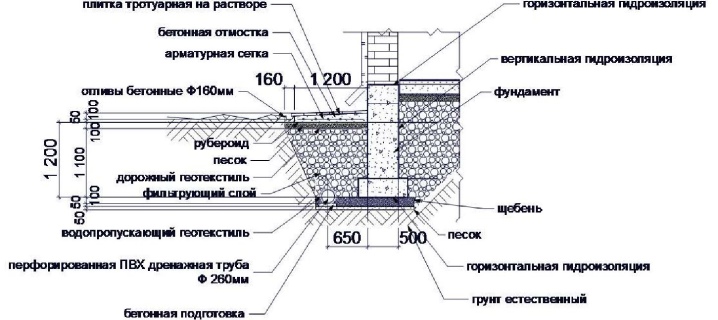

The second stage of trench preparation - waterproofing or so-called separating... It is needed to protect the concrete layer from excess moisture during its maturation. Either a geomembrane or plastic wrap is used. Its thickness is not less than 200 microns. If necessary, make additional thermal insulation. For this, a layer of extruded polystyrene foam is laid on top of the film.

The most important stage is installation of formwork. Most often it is made of wood. In parallel, you need to set the slats to mark the expansion joints. They are installed at a pre-designed formwork level, taking into account the required angle of inclination. The lath width should be 20 mm and the height should be more than a quarter of the formwork thickness.

The method for calculating the distance between the seams is as follows: the thickness of the concrete layer near the base is multiplied by 25. It is most convenient to combine temperature and technological joints: that is, concrete should be poured, focusing on the slats. One serving is poured between two slats. Near the base, it is necessary to make an expansion joint with a thickness of 4 mm or more. Most often, roofing material is used for this. After that, the future formwork is reinforced. The simplest method is to use a road grid.

It is recommended to choose a mesh with cells of 10 centimeters and a diameter of rods of at least 4 mm.

Reinforcement Is not the last step in this process. After its completion, they begin to fill the structure with cement mortar. The most suitable composition is concrete M300. It is undesirable to save on the quality of concrete, since the durability of the blind area depends on it. Recommended proportions for mixing - 3 shares of sand for 1 cement.

It is important that the concrete dries a little, and then you need to cover it with a waterproofing film for two days.

This is necessary so that the moisture that concrete needs to give strength does not have time to evaporate. Otherwise, the concrete will begin to crumble and quickly deteriorate. After 2 weeks after pouring, the slats are removed, and the seams are poured with bitumen mastic.

Let's consider the main mistakes during the installation of the formwork.

- Laying formwork without tilting... If there is no slope, the water that gets on the formwork will not flow down, and the main function of the structure is to protect it from moisture.

- Pouring cement without regard to expansion joints. The stress that occurs in blocks at elevated temperatures leads to fractures in the concrete.

- Creation of gaps in the formwork. This guarantees the flow of moisture under the ground, including where there is formwork. The blind area must be built around the entire perimeter of the building.

- Poor bottom ramming. If the bottom of the trench is not sufficiently compacted, soil shrinkage occurs, due to which the concrete coating begins to collapse.

For information on how to correctly and at no extra cost to make a blind area around the house, see the next video.

The comment was sent successfully.