Features of fibrous refractory material

Refractory fibrous materials are in demand in construction, industry and other areas. Refractories include special heat-insulating products containing fibers. It is worth considering in more detail what this material is, where it is used.

What it is?

Refractory material is a special industrial product based on mineral raw materials. A distinctive feature of such refractories is the ability to operate the material at elevated temperatures, which makes it possible to use refractories for the construction of various structures and protective coatings.

The raw materials are mainly:

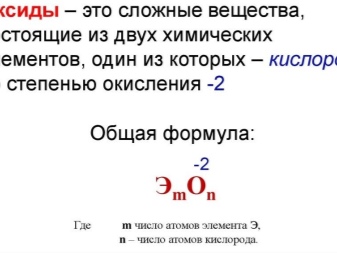

- complex oxides;

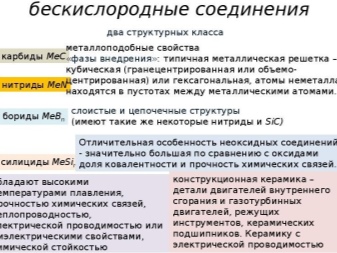

- oxygen-free compounds;

- oxynitrides;

- sialons;

- oxycarbides.

For the production of refractories, different technologies and stages are used, among which the most important is the heat treatment of the product. Also, the future product is exposed to:

- crushing the components of the composition;

- the creation of charge;

- molding;

- pressing.

The last stage is carried out on special mechanical and hydraulic presses. The material is often subjected to extrusion followed by additional pressing.

Less often, refractories are made in gas-chamber furnaces in order to obtain certain properties. In the process of manufacturing products, manufacturers can add various minerals and other additives to the composition of the future refractory, which can increase its operational properties.

The main characteristic of a refractory fiber material is refractoriness. In other words, the material is able to withstand operation at high temperatures without losing its appearance or melting.

The refractory index is determined by testing on specially prepared samples: truncated pyramids up to 30 mm high, with base dimensions of 8 and 2 mm. This pattern is called the Zeger cone. During the test, the mold is softened and deformed to such an extent that the top of the cone can touch the base. The result is the determination of the temperature at which the refractory can be used.

Refractory products are manufactured for specific purposes and for general use. The properties and characteristics of the material are prescribed in the passport or regulatory documentation, as well as the options for the possible operation of refractories.

Advantages and disadvantages

The main advantage of refractory fiber material is its increased resistance to fire. Additional advantages of refractory:

- low coefficient of thermal conductivity;

- resistance to aggressive environments.

Also, refractory materials are characterized by increased strength, which makes it possible to use them as a protective coating for various equipment. The only drawback is the high price, which is explained by the special technology of refractory production. However, such a minus does not stop the owners of various enterprises from purchasing products that are resistant to high temperatures and open fire.

Applications

Fibrous refractory material is in demand in many areas, and the field of use of such products continues to expand.

- Coke ovens. Refractory is used for finishing molds in coke oven hatches in order to increase insulation.Low thermal conductivity contributes to a rapid increase in the temperature of the refractory surface and the elimination of deposits of resinous products. The result is a reduction in heat losses during the operation of the furnace. Also, materials made of refractory fibers are famous for their good compressibility and elasticity, which allows them to be used as a sealing medium between furnace elements.

- Agglomeration plants. Basically, the material is needed to ensure the external insulation of the structure. With its help, refractory lining of the exhaust hoods of the considered installations is performed. The advantage of using such a material is to reduce fuel consumption and save on water cooling.

- Iron production. Fibrous materials provide hot surface insulation for ironmaking equipment. In the process of using refractory, it is possible in a short time to increase the temperature of the pipeline to the required parameters, to prevent the occurrence of heat losses.

- Steel production. Refractories are used to cover open-hearth furnaces where expansion joints are required. When it comes to converter steelmaking, the fibrous materials are mounted on heat taps in order to ensure the required insulation values. Additionally, fiber covers ensure reliable operation of thermocouples and instruments that are necessary for determining the composition of steel.

- Casting steel. Fibrous materials in this case play the role of seals. They are installed between the base plate of the equipment and the mold to prevent oil leakage. Also, liners are made of refractories, through which it is possible to organize reliable thermal insulation of the upper part of the furnace for casting expensive steels.

Refractory fibrous materials are used in many industrial and construction applications. With their help, it is possible to reduce production costs and improve the thermal insulation properties of most processes. Also, refractories prevent heat loss, provide reliable protection of various elements in case of operation at high temperatures.

The use of fiber lining can extend the service life of various equipment up to 4 years or more. Refractories are characterized by high performance characteristics and resistance to high temperatures, which makes them so popular.

The comment was sent successfully.