What are metal files and how to choose them?

Grinding metal surfaces may not always be done with electric tools. Sometimes files for metal are used for such actions. But, of course, you need to find a suitable option for the implementation of a certain type of work.

Files can be used for metal or woodworking. The first type usually has a higher hardness than similar solutions for wood. This is not surprising, because the surface of the metal is harder. Let's try to figure out what such devices are and how to choose a really effective option for a specific situation.

general description

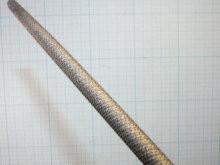

A file is a tool used to remove a layer of metal from a workpiece. It is usually a metal strip equipped with a notch. This is the name of the cutting teeth made according to the standards of GOST under the number 1465-80.

To operate such a device, you should use a handle, which is usually pushed onto the shank made. Various types of steel are used to create such a device. Usually, the steel grade used to design the devices under consideration is ShKh15 or U10A, which contains 1.1-1.25 percent carbon.

By the way, the latter brand is included in the category of non-alloyed improved ones.

The main requirement for a steel grade is hardness. It is for this reason that this type of file is not tempered after heat treatment. In working mode, the surface of the fixture should have a hardness of 55-59 HRC.

The handle, which makes it possible to use the tool, can be made of various materials - plastic, wood or some metals. Let us add that the files may differ in shape and have different parameters of the teeth for cutting.

The abundance of various groups of files makes it possible to produce quite a few different categories of work. For example, with the help of such a device, you can grind the planes of various kinds of workpieces, remove sprues and burrs, dirt. And if the tool has a special shape, then you can do the processing of gear-type gearing, as well as sharpen the chains that are used in saws.

Species overview

It should be said that the classification of files by metal provides for their distribution into categories according to various criteria. They are usually classified according to the following criteria:

- the size of the teeth;

- form;

- purpose;

- type of notches.

Let's try to understand this issue in more detail.

By the type of notches

If we talk about the types of cuts, then files can have the following types:

- single;

- rasp;

- stamped;

- cross;

- arc.

The notch of the first category is usually used for processing non-ferrous metal surfaces. The use of this type allows you to quickly remove the blank layer and make effective cleaning of chips.

When using this type of instrument, it rattles a lot, which makes the hands get tired very quickly.

It should be said that the processing of metals with high hardness with such a tool is impossible due to the peculiarities of the teeth. Namely, the angle of inclination. Application here is done at a 25 or 30 degree angle.

The rasp or point type cut is usually used for accelerated removal of scale or rust on metals classified as ferrous. Its greatest efficiency is shown when processing coarse wood.

The third type of cut is usually used in the same cases as a rasp. The difference in this type is in the teeth - they are inclined. Thanks to this, they hook the workpiece like hooks and, as it were, rip off. A tool with a similar cut creates the coarsest grooves. The stripping off of the teeth occurs extremely quickly. Therefore, such a file with high hardness metals is usually not used. But for a tree, this is an excellent solution.

Also, a similar tool is used for processing aluminum. But the negative point is that the blade will quickly become clogged with chips, which are very difficult to pull out.

A cross cut is usually needed when machining metals such as bronze, cast iron and steel is required. Its barbs intersect to form a rhombic pattern. The angle of inclination of the main notch is 25 degrees, and the additional one is 20 degrees more.

This type of file can also be clogged with chips in a short time. Therefore, for working with metals with low hardness, this is an inconvenient option. We add that in order to ensure comfortable and efficient work, you should have a metal brush, which is sometimes required to be used to brush off the chips between the teeth.

Arc will show the best efficiency when processing non-ferrous metals and wood species with high hardness - beech and oak.

After using a tool of this type, only neat scratches can be seen on the workpiece, which can be easily sanded.

By destination

According to this criterion, files are divided into the following groups:

- general;

- special;

- needles;

- rasps;

- machine or tape.

Files belonging to the first category are more often used to carry out locksmith work. They differ from others by the presence of a double notch with teeth applied by the notching method. They are different in length: 100, 200 mm and up to 450 mm, and the teeth are almost all numbers.

Special-purpose tool models are usually used in production, because they allow you to eliminate serious allowances when you need to adjust grooves or surfaces of different curvature. By the type of work carried out, the files of the category in question can be grooved, flat, with a pair of ends, and others.

The most numerous category is needle files. They come in 11 categories, and their characteristic features are the presence of grade 5 notches and a small block length. They usually have a double notch.

It is always best to have a set of files. They are used to process various small parts and places that cannot be reached with ordinary tools.

Rasps are:

- shoe;

- general;

- ungulates.

Their main feature is the presence of teeth with large dimensions and serious length. Usually rasps are circular or semicircular, or can be flat, with a blunt or sharp nose.

Machine tools represent a separate category of tools that differ not only in the method of application, but also structurally. A file like this is sandpaper made like a round tape. It is attached to an electrical appliance, after which it is used to carry out the required work.

Band models are an alternative to tools. For example, there are models for a screwdriver or a file-drill for a drill.

But a number of disadvantages do not allow this type of files to become a full-fledged replacement for locksmith tools.

By form

Thanks to the shape of the existing tool, the segment of its use can be calculated:

- triangular metal tools are usually used for machining in grooves and holes;

- a square analog will be used for sawing holes that have the shape of a polygon, square, rectangle;

- round analogs are required for processing concave surfaces with a small diameter, as well as holes in the shape of a circle and an oval;

- the rhombic tool is taken to work with gear parts;

- semicircular are needed for processing large holes and concave surfaces with a rather large radius of curvature;

- hacksaw-type models are used for sampling grooves and grooves of a narrow type;

- simple models or analogs with a sharp nose are used when it is necessary to treat a flat type surface.

Tooth size

According to this criterion, the notches of the devices under consideration are divided into 5 classes.

- Classes 0-1 can remove a layer with a thickness of 0.05-0.1 millimeters. These are the largest cut options. The main disadvantage is that when processing metal surfaces, errors of 0.1-0.2 millimeters can occur.

- Classes 2-3 remove a layer with a thickness of 0.02-0.06 mm. This is the most commonly used solution for metal stripping. But its effectiveness for cleaning holes and grooves will be small.

- Classes 4-5 can carry out the removal of the 0.01-0.03 mm layer. Typically, such notches are used for finishing and finishing grooves and holes to the required state. The maximum error in operation that can be observed will be 0.001-0.005 mm.

What material is it made of?

As already mentioned, this tool should only be made from extremely hard tool-grade steel of the highest quality. For example, from brands:

- ShKh15 or 13Kh - these are the categories of alloyed chromium steel;

- U10A or U13A, related to improved unalloyed brands.

Fixtures are processed by hardening, which is why their hardness values will vary in the range of 54-58 HRC. These grades are used to create files that will be required for working with metal.

If you have to work with wood and other materials, then use softer steel.

A similar notch, called "simple", is present in special files. Such models are necessary to remove a small metal layer during filing. Special files are usually used for processing narrow surfaces.

Besides, they are convenient to use when you need to sharpen the saw on wood. Although it would be better to use an electric file here. The electric analogue will simply allow you to do this faster. In addition, such products are used for working with wood, plastic, and metals with high softness.

Marking

If we talk about the marking of such a tool, then something was said above about the classes. There is another type of marking where graininess plays an important role. Here, the largest grain size notch will be number 0, and the smallest - number 5.

The considered instruments are of the following types.

- Gourmet. These include models No. 0-1 with up to 12 notches per 10 mm of surface. These models have fairly good teeth, which makes it possible to scratch off a large layer of rust.

- Personal and semi-personal. This includes models # 2-3 with 13-44 notches. They are usually used for the processing of various metals.

- Velvet. These are models # 4-5 with 45-80 serrations. They are used for final processing, and they remove the thinnest possible layer of metal.

Popular manufacturers

Let's make a small rating of file manufacturers whose products really deserve attention. The first one I would like to mention is the Cobalt brand. Cobalt files are widely used by many craftsmen and specialists. Among the strengths of the brand's products are:

- a wide range of different models;

- high quality carbon steel is used to create tools;

- all handles are made of high-quality plastic and have rubber pads, so that the tool does not slip in the hand.

Another interesting brand that deserves attention is Sibrtech. This domestic company boasts a wide range of different types of metal files. They are made of high quality alloy and high carbon steel.

The company's products are distinguished by high durability, ease of use, as well as an affordable price.

The third brand worth saying a few words about is Zubr. The company also belongs to domestic and produces good metal files of various types with high strength, excellent ergonomic handle and quite competitive cost.

Selection Tips

Now let's try to briefly outline how to choose a good metal file. Here it should be said that you can choose a good file:

- when a person clearly understands what exactly needs to be achieved when processing a particular detail;

- which layer of material needs to be removed;

- if there is a need to remove a layer of material 0.1 millimeter thick, then you can use a tool with a notch 0 or 1;

- if necessary, perform delicate work, for example, prepare a surface for subsequent coating, it is better to take tools with number 2-4;

- for work where it is required to thread the cutting edge or sand the surface, it would be better to use velvet tools.

Application rules

Now we will briefly describe how to work with a file correctly so that its work is effective.

- First, you need to firmly fix the part that will be processed. To do this, you can use a clamp or a vice.

- The workplace must be well lit so that the workpiece is not accidentally damaged.

- Now you need to choose a suitable file. To do this, you first need to assess the condition of the workpiece. If you need to remove a lot of metal, then it is better to use a baked model. If not, then it is recommended to take a personal or velvet type model.

- The file should be prepared for work, especially if it has already been used before. It is necessary to clean its working part with a metal brush.

- You can take the required actions. We take the tool with one hand by the handle, and the other by the heel. When it moves forward, it should be pressed against the workpiece.

- The movement should continue until the end of the notches at the heel. Then there should be a movement back with a decrease in the effort of the hand.

Thus, with the help of reciprocating movements, processing will be performed. After that, it remains to assess the state of the workpiece. Usually at the end it is necessary to carry out processing with a velvet file, but it all depends on each specific case.

The comment was sent successfully.