All about flat files

Any tool must be properly used and properly cared for. Any products with sharp parts need to be sharpened from time to time. To cope with this task, files must be used. The variety of these products allows you to maintain the performance of different tools. In order to choose the right file and use it correctly, you need to know what types and forms of these products exist.

Characteristic

The file is a hand tool with which it is possible to process various surfaces. It consists of a bar of different shapes and sizes, as well as a handle. The most common tasks this tool handles are:

-

cleaning tools and surfaces from traces of rust and corrosion;

-

removing dirt, paint and other unnecessary coatings from surfaces;

-

changes the size of parts, adjusting them to the required dimensions;

-

allows you to sharpen tools used in work and everyday life;

-

helps to clean electrical contacts;

-

is a means of polishing and grinding metal and other surfaces.

Different types of files are used depending on the task. A flat file is considered the most popular option for sharpening equipment and grinding surfaces. In order to correctly select these products for other tasks, it is important to know about their species diversity and basic functions.

Now you can find a large number of sets of files of different shapes, sizes, made from different materials, but not all of them will correspond to the proper quality. GOST has clear characteristics of files, by which you can choose a good option.

These will last a long time, and will fulfill all the tasks assigned to them.

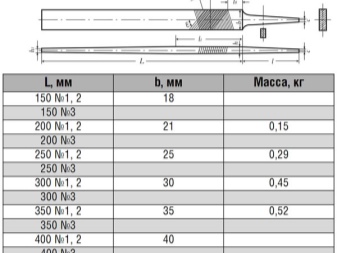

Dimensions (edit)

Depending on the size of the parts with which you have to work with the file, there is a need to select the correct size of the product. The smallest is the short version of 150 mm, which is most convenient for working with small elements. Depending on the length of the product, the notch on it will differ. Small files with a length of 160 mm have a smaller cut, although they will be marked with the number 2 in the same way.

Large file sizes include 200 mm, 250 mm and 300 mm. The notch for these products will be much larger, but they are also marked with the number 2. A very small file of 150 mm has the smallest notch, velvet and marked with the number 3. The velvet size does not differ much from the nail file, which has a size of 400 mm, but the grain size of the second option will be much larger, although it is also marked with the number 3.

A table in which the types of products, the number of notches and their length are described can help you to navigate well in the size of the files and in the size of their section.

The file sets can also indicate the main characteristics of each of the product options.

Views

The scope of use of files is quite wide, therefore there is a wide variety of forms of these tools.

-

Flat - designed for flat surfaces. There are blunt-nosed and pointed-nosed versions of the product.

-

Triangular tools - used to process grooves, holes, grooves;

-

Square files - Suitable for larger hole diameters.

-

Round and semicircular - work with concave surfaces and holes of the appropriate diameter.

-

Hexagonal - suitable for working with surfaces of complex shapes.

In addition to the gradation in shape, it is worth mentioning the purpose of the files, since this parameter allows you to select the correct version of the tool for the job.

-

Locksmith - general purpose file. Suitable for metal processing and household needs.

-

Straightening - designed for surface straightening. Its shape differs from other options, as it is curved, like a trowel.

-

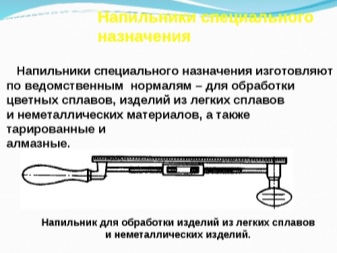

Special - allow you to reduce allowances, handle curved surfaces and grooves.

-

Sharpening - used for sharpening chains on electric and chainsaws.

-

Automated - used as an element of the machine tool in production.

-

A file is a miniature version of a file created using metal rods. With a small section, it is necessary for working with small objects.

-

A rasp is a tool with a large and rare notch, with which the surface of a stone, wood or plastic is processed.

Despite the simplicity of design and ease of use, files are represented by a large assortment of products that must be disassembled in order to use them correctly. One of the important factors is the type of cut on the file blade. According to this criterion, there are:

-

bastard (No. 0-1) - the coarsest version of the notch, optimal for processing steel or cast iron, has from 4 to 12 teeth per 1 cm;

-

personal (No. 2-3) - the middle version of the notch, has from 13 to 24 teeth per 1 cm, is used for finishing metal surfaces;

-

velvet (No. 4-5) - the smallest version of the notch, used for grinding soft metals, has 24 teeth per 1 cm.

To work with different surfaces, files must have not only a different number of teeth per blade, but also a different material of their composition. Most often, there is a carbide version of this tool, which has a tungsten carbide spraying, which allows you to confidently work with most coatings. The highest quality, durable and expensive products are diamond-coated. The cost of such a tool is several times higher, but the result is worth the money.

The diamond file is capable of cutting the surface of the hardest metal surfaces.

When choosing files, you should also pay attention to the handle, as it can be made of different materials:

-

wood, mostly hard varieties;

-

plastics;

-

rubber.

Wooden - handles are the oldest option, they are easy to use, but cracks and breaks over time. The plastic handle is devoid of such problems, but during use, the hand may slip off it, which is unsafe.

A file with a rubber handle is considered the most successful, it does not break, does not rot, does not slip and retains its appearance for a long time.

Appointment

Since there are quite a few file options, there is a clear division according to the scope of each of them.

-

For metal - allow you to remove edges in workpieces, clean the surface from traces of rust, sharpen the cutting edge of tools and grind parts. The cut of these files can be single or double. The teeth have 5 gradation options: 1 (0.1) - rough metal processing; 2 (2,3) - used to clean the layer up to 0.06 mm; 3 (4.5) - needed for finishing metal. Types include: general files, special files, needle files, rasps.

-

By wood - necessary for the treatment of wooden surfaces. They can have single, double, arc, rasp notches. For small work, file and riffle are used. The rasp has a species diversity, distinguish: flat blunt, semicircular, round and cabinet options.

-

For tiles - files for special purposes. Carbide products, with which you can work the edges of tiles, cutting off sharp parts and smoothing out dirty joints.Using tools of different shapes, you can grind and smooth holes in tiles, as well as give this material the desired shape of the edges.

Focusing on the types of files, you can easily choose the options you need for yourself.

Choice

When planning the purchase of a file, you should pay attention to such parameters as:

-

number and material of teeth;

-

notch type;

-

product shape;

-

tool length;

-

handle material.

The size of the file should be chosen so that it matches the dimensions of the surface to be treated as much as possible. The handle should be taken so that it fits comfortably in the hand and is reliable. The shape of the tool must be the same, the notch must be uniform. To check the quality of the file, you can hit it on metal and listen to the sound. If it is clean and sonorous, then everything is fine, but if there is a rattling, then cracks in the instrument are likely.

It is worth paying attention to the color of the file, there should be no rust and abrupt shade transitions on it, gray is considered optimal.

It is best to choose products from proven brands that have proven themselves.

The comment was sent successfully.