Unis plus glue: types and applications

In order for the tiles to adhere firmly to the surface, it is necessary to use reliable and high-quality tile adhesive, which would adapt to all the features of the room, for example, the bathroom. Many of those who started repairs prefer Unis plus glue. What are its features and how has it earned recognition in the market?

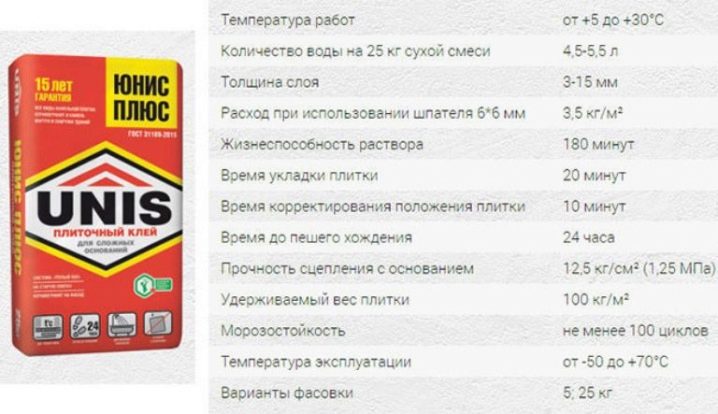

Characteristic

This glue is universal and can be used for various applications both indoors and outdoors. He has a cement base with mineral fillers and other chemical reagents, due to which this mixture has high-quality technical characteristics:

- High coefficient of adhesion.

- Moisture resistance, which is especially important for cladding rooms with high humidity or swimming pools.

- Resistant to temperature extremes. The properties of the glue do not change regardless of weather conditions. It can withstand temperatures from -50 to +70 degrees.

- The mixture has an environmentally friendly composition, therefore it does not cause allergies.

- The mortar, and with it the tiles, will not begin to slide off the wall, because the glue is plastic. It is firmly fixed to the surface.

The mixture is easy to prepare and apply, while the consumption of glue is quite economical and is approximately three to four kilograms per 1 m2 (it all depends on the size of the tiles). The mixture is usually sold in bags weighing 25 kg, which simplifies the task of calculating the amount of glue for certain finishing works. A 25 kg package is enough for an area of 8 square meters. The glue dries within twenty four hours.

How to properly prepare the surface?

In order for the tile to lie flat, you must first carefully work with the base and prepare it as follows:

- Old finishes are removed, whether screed or crumbling plaster.

- If the surface is in cracks and other defects, then the base is leveled with plaster.

- The surface must be dry and free from any dirt and oil stains.

- If the room is with high humidity, then before work it is better to complete the procedure of coating waterproofing.

- A primer is necessary to ensure that the base for laying is flat. So the grip will be more reliable and durable. If the surface is not leveled, then the tiles will begin to flake or crack over time. It is better to prevent these consequences in advance.

How to mix the solution?

A suitable container is required for this procedure. All tools must be clean.

Algorithm of work.

- The glue must be diluted in the ratio of 250 ml of water per 1 kg of dry composition.

- Then the resulting mass must be stirred for three to five minutes. It is best to do this with a special mixer or drill, which has a special attachment. If none of the above is present, then you can stir the glue with your hand. As a result, a homogeneous consistency should be obtained.

- It is important to remember that the properties of the mixture after preparation are retained for only three hours, therefore it is important to correctly calculate the amount of glue required for a certain amount of work. When thickening, the mixture is mixed again, no need to add water.

- If you do not observe the proportions, add additional components to the solution, do not follow the recommendations in the instructions, then the resulting mixture may not correspond to the declared characteristics.

How to apply?

After the surface is prepared and the glue looks like a uniform consistency, you can start applying it to the wall or floor.

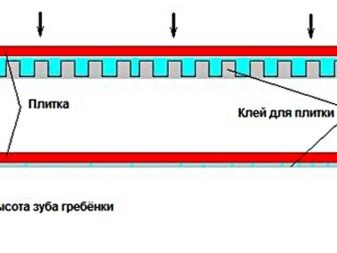

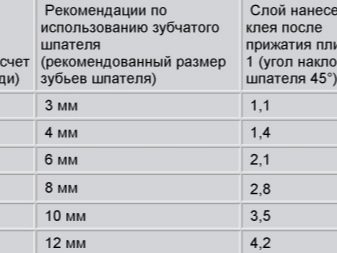

This process requires a spatula. With the help of it, an even layer of the composition with a thickness of 3 to 15 millimeters is applied; one must not forget to level it with a special grater or a spatula with teeth. If the squares of the tiles are large, then the teeth should be from 8 millimeters.

It is important to keep an even distribution of the adhesive mass. The voids will turn into unpleasant consequences in the future, so it is better to press the tiles a little to the surface.

After the material is laid, it can still be corrected within twenty minutes. The glue dries exactly one day. Then you can move freely on the tiles (if the finishing work was carried out on the floor) .After the completion of the work, you need to remove the excess adhesive mass that remained on the front of the tile and grout joints. If the excess composition remains in the seam, then a number of problems may arise when grouting begins.

Possible consequences.

- If you apply grout to an unrefined seam, then in the future it will begin to crack, because it will be thin.

- Another reason to remove glue residues is for aesthetics. If a sticky mass peeps through the grout, then no matter how beautiful the tile is, its appearance will be spoiled.

- The use of colored grout on the joint with glue residues will result in the fact that after drying it will differ in color from the rest of the grout. The thing is that in this place it will be thin and not so strong. The result will be sloppy.

To avoid these unpleasant consequences, you need to remove the remnants of the glue while it is soft, otherwise it will be much more difficult to do this later. You will need a knife for the procedure. Using its blade, it is easy to remove the remnants of the adhesive mass from the edges of the tiles.

If the mixture has already frozen, then here you need to use a special knife, which is intended for the grouting joint. First, make a cut in the center of the joint and scrape dry glue off the edge of each tile with a knife. If necessary, you can clean the tiles with an abrasive trowel. And at the end of the procedure, the seams are cleaned with a vacuum cleaner so that not a single small particle remains of the glue.

Another important tip: after laying the tiles, you should not immediately start grouting the joints. You need to wait for the glue to "set", the drying time is indicated on the package. If the sticky mass is still wet, and the grouting process has already begun, then in the end result it may appear of a different color. Therefore, it is important to strictly follow all step-by-step instructions both in the dilution of the glue and in its application.

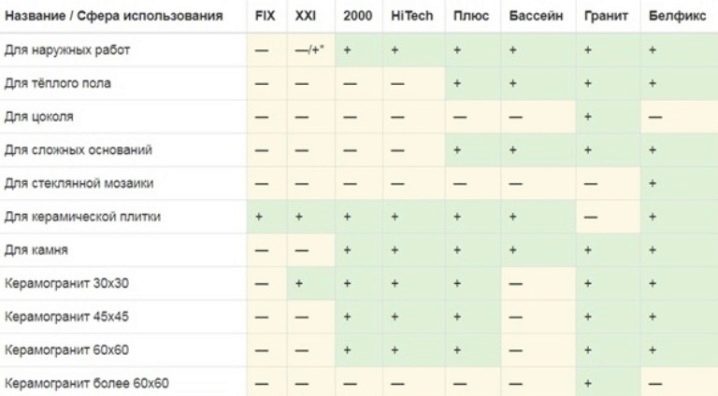

Views

Unis offers a wide range of adhesives. Each of them is designed for a specific type of work and has individual technical characteristics.

As for the "Unis plus" glue, it is universal, it can be used for various types of materials. It is safe and used for repairs in institutions with small children. The glue is suitable for any other finishing work (only the plinth facing is impossible with it). It is sold in red packaging.

Its characteristics:

- the applied layer should be no thicker than one and a half centimeters;

- the properties of the glue do not disappear for three hours during operation;

- you can correct the tiles after laying within fifteen minutes;

- glue dries 24 hours;

- withstands extreme temperatures from -70 to +50 degrees.

Unis 2000

This type of mixture differs from its predecessor in that it does not have high frost resistance, therefore it is not recommended to use it in extreme conditions. This glue is usually used for ceramics, concrete for interior and exterior wall cladding.

Peculiarities:

- the composition hardens after about 36 hours;

- it is possible to correct the position of the tile within ten minutes after it is laid;

- temperature range during proper operation - from -50 to +50 degrees;

- the glue is able to withstand a large tile weight - up to 80 kilograms per m2.

Unis XXI

This product is commonly used for indoor and outdoor floor and wall tiles. It tolerates moisture well, which is its great advantage.

Specifications:

- the adhesive is applied in an even layer not exceeding ten millimeters;

- does not lose any of its properties for three hours;

- withstands temperature conditions from -50 to +50 degrees.

- weight restrictions - no more than 40 kilograms per square meter.

Unis Granite

This glue is capable of withstanding heavy weight (up to 110 kilograms per square meter), so it can be used to work with slabs of stone, as well as with porcelain stoneware. Suitable for finishing not only walls, but also a facade with a plinth. Its composition is safe, therefore it is widely used in childcare facilities. Peculiarities:

- with this glue, you can not be afraid of slabs slipping, so it is used for finishing not only walls and floors, but also ceilings;

- the solution has increased frost resistance, it is easy to work with it outside the room;

- the mixture dries for about 36 hours;

- sold in packs of 25 kilograms;

- to prepare a solution, you need a mixture ratio with water of 5: 1;

- the properties of the glue are maintained for three hours, and it is possible to correct the position of the tiles or other facing within 10 minutes after laying.

Unis HiTech

Complex surfaces lend themselves to this glue, while laying can be done as usual, or in the direction from top to bottom.

Specifications:

- layers applied to a particular base can reach one and a half centimeters;

- correction of the material after laying can be carried out within fifteen minutes;

- the properties of the prepared solution are not lost up to five hours of operation;

- environmentally friendly and does not cause allergic reactions;

- with regard to the consumption of the mixture, it is three and a half kilograms per square meter.

Unis Belfix

The adhesive is designed for difficult work with such types of materials as tiles, marble, mosaics, etc. It is resistant to frost weather and elastic. It can be used for both outdoor and indoor decoration, especially including wet rooms. Its cost is higher than its predecessors.

Properties of this glue:

- to prepare a homogeneous mass, a ratio of 5: 1 is required;

- an adhesive layer is needed no thicker than one centimeter;

- time for correcting errors when working with tiles - 15 minutes;

- like other types of glue, it does not lose its properties within three hours after preparation;

- operating temperature - from -50 to +70 degrees;

- the composition dries for 24 hours.

Unis Fix

This type of glue can be called the weakest among other assortments of this brand. It has a low price and is suitable for laying ordinary tiles in the bathroom, kitchen, on the balcony.

The main properties of this product:

- the mixture is placed in water in a ratio of 5.5 to 1;

- the applied layers should be no thicker than one and a half centimeters;

- you can adjust the position of the tile within ten minutes;

- drying time - twenty four hours;

- this glue is sold in packs of 25 kilograms, but it is this type of mixture that is rarely found on store shelves.

Unis Pool

Judging by the name, you can guess where this type of glue is used. Its area of action is damp rooms and even the inner surface of swimming pools or jacuzzis. It is applied to ceramic tiles, mosaics, concrete, brickwork, plasterboard, old tiles.

The glue has quite high technical characteristics:

- resistance to moisture, which corresponds to its intended purpose;

- glue can withstand temperature drops of one hundred degrees;

- the material is consumed sparingly - a little more than three kilograms per square meter;

- the solution does not lose its characteristics three hours after dilution, so you should calculate the required amount of the mixture for a certain area (this applies to large areas) and divide the mixture into portions;

- what the thickness of the applied layer swings, then it should be 3-6 millimeters;

- there are ten minutes to correct and level the errors on the tile;

- the glue dries within a day, during which time it is forbidden to walk on the tiles (if the finishing work was carried out on the floor);

- operating temperature - from -50 to +70 degrees.

These are the main types of Unis Plus adhesives. Each of them has its own technical characteristics and is used for a certain type of facing work. You should pay attention to the listed properties so as not to make a mistake in choosing the glue of this brand.

Product advantages

Feedback from buyers who purchased Unis Plus glue for finishing works is mostly positive.

Among the advantages of this product stand out:

- rich assortment (for different types of surfaces);

- convenient packages of 25 kg;

- durability and efficiency;

- the glue is easy to dilute and apply;

- for each type of product, instructions for use are attached, which greatly facilitates the work with this composition;

- the glue is made in accordance with GOST and has all the certificates of conformity.

Unis plus is quality products at an affordable pricesuitable for cladding a wide variety of surfaces. The main thing is to follow the instructions for use, and the end result will delight the eye for many years.

Comparison of tile adhesive from different manufacturers is clearly presented in the video.

The comment was sent successfully.