Lead screw overview

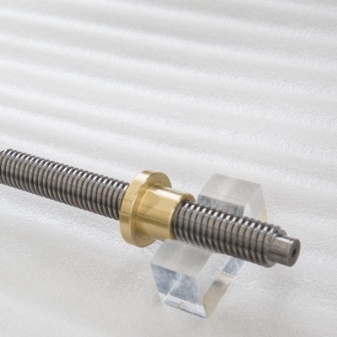

An overview of the lead screws is very important for a variety of mechanical systems and applications. There are such modifications with a nut for swamp vehicles, trapezoidal for a lifting and lathe, for a vice, for CNC machines and other types. They differ in the fixing methods.

What is it needed for?

The lead screw is used most often in machine tools where threads are cut. Its rotation turns into a translational movement of the support due to the mother nut. To control the rate of twisting, that is, the intensity of the feed, a special box is used. A special nut is required for the work of the lead screws. Modern designs guarantee the movement of parts with precise precision.

As for the propellers for swamp-going vehicles, in this case they play a completely different role - they are cast rowing structures. Suspended motors are equipped with such products. Large suppliers usually have substantial stocks of such parts in their warehouses.

The vise lead screws also play an important role. All such parts are made of high quality steel, often they are finalized using lathes.

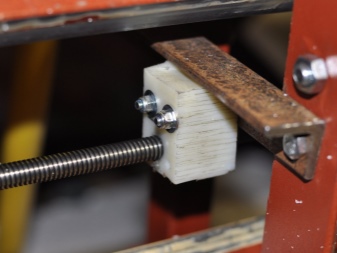

It is impossible to count on getting a lead screw at home. Even if you can buy this or that model of a lathe, you will still need other tools, special cutters that allow you to form threads of the required sizes and types. The main role of the screw is to maintain a linear motion. The size of the parts has its own limitations, which are determined by the design of the vice. But lead screws can also be used for various types of CNC. These details again perform the most important function - the transformation of movement.

The lead screw in modern machines can differ in different designs. In homemade samples, a threaded rod is sometimes used. A more perfect option is the "screw-nut". Sometimes they also take a trapezoidal screw, but despite the increased strength, this type of ligament is quite expensive, and therefore is used less and less. The lead screw can also be used as part of a lifting mechanism. Also similar components are common parts:

- thread drive in a screw press;

- presses of other types;

- feeders of various tools.

Types and characteristics

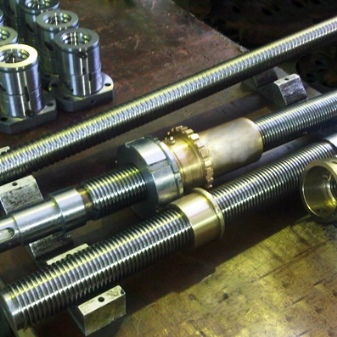

The description of the parameters of the lead screws is appropriate to start with the fact that they are always used as an integral part of a more complex mechanical chain. The accuracy of movement of individual parts of mechanisms depends on their quality and compliance with the necessary parameters. The most important grading criterion is the thread section. In most cases, trapezoidal cuts are used. This approach makes it possible to achieve much higher mechanical strength than in other cases.

If a split nut is additionally used, then it will be possible to carefully adjust the axial clearances. Preparing and grinding trapezoidal threads is fairly straightforward. However, in a number of situations, a rectangular thread will be more attractive. It allows you to minimize the radial runout of the screw, so the deviation from the optimal path is also reduced.

Such performance is especially valuable in those branches of technology where the accuracy of movements is in the first place.

The trapezoidal grooving system is typical for sliding gears. In this case, small profile angles are very useful. Most often, a medium cutting step is used, and small and large ones are used for special tasks. A fine step is recommended for relatively accurate and slow mechanisms. Large - in cases where there is a significant load.

The modern machine tool industry is increasingly using "rolling screw pairs". Especially many of these parts are used in software-controlled equipment. In this case, the lead screw is combined with a nut. So that they are clearly mated, special balls are used. The screw pair cannot brake itself; it is used when converting a rotary motion to a translational one and when changing back.

In fasteners of the classic type, a single-start thread is usually used. It all consists of a single spiral, the intervals between the turns are strictly the same. For the turn of the nut, a shift occurs at a strictly defined distance. A multi-start thread is formed by two or more spirals. The principle of keeping the same distance is still observed, however, there is a larger gap between the turns in each spiral than between the turns from different spirals.

The technical characteristics of the equipment in which it is installed depend on the material and dimensions of the hardware. For example, for jacks, this indicator will be the total load capacity. For the manufacture of lead screws, nitrided steels of grades can be used:

- 40XFA;

- 30X3VA;

- 18HGT;

- 7HG2VM.

There are such dimensions as:

- 10x1.5;

- 10x2;

- 10x3;

- 10x4;

- 10x7;

- 10x8;

- 10x12;

- 10x14 mm (and some other options).

Continuing the conversation about the dimensions of the lead screws expressed in mm, it is worth pointing out the model TR30x6 (as its name implies, the cross-section is 30, and the cutting step is 6 mm). The total length of the product is 3000 mm.

You can also find designs with a diameter:

- 160 mm;

- 20 mm;

- 8 mm (and some other values).

Mounting methods

In some cases, simple bearings of model 61701 or their exact counterparts are used to strengthen the structure. The tightening should be done carefully, with the selection of gaskets to avoid jamming. Automotive probes are used for the manufacture of gaskets. The trapezoidal screw is secured in the bearing bracket with suitable sized nuts. A more accurate and efficient solution is the machining of the ends.

It is very difficult to do such a manipulation with ball screws - they have hardened surfaces. The usual metal of an ordinary screw, especially due to the trapezoidal shape, is processed without problems. In serious cases, telescopic protection of the undercarriage fasteners is used. It is usually supplied for each individual lathe model separately. In gearboxes, special cuffs help protect the lead screws.

For the manufacture of such cuffs, carefully selected materials with increased wear resistance are used. If the calculation and precise processing of the lead screw for the required dimensions is difficult, you will have to use special ready-made kits. When self-manufacturing fasteners, you will also have to make a corresponding nut. In the case of a lathe, a double nut is needed, because a single nut can be greatly affected by the gap that appears during the manufacturing process or during operation.

The hole when installing the lead screw on the machine must be made with a tolerance for subsequent pressing. The shaft can be slid fit. Yes, in artisanal conditions it is quite difficult to reach such a level (for example, h6 / L0), but it is very important.

Otherwise, due to a mismatch in quality, there will be an unreasonably strong backlash, and one cannot rely on the accuracy of the machine's operation. The actual pressing-in procedure at home is quite possible if you use a slightly modified bearing puller.

The hole should be smooth. Surface parameters - not worse than Ra 0.64. Therefore, it is guaranteed that you cannot do without the help of professionals. In some cases, thread sealant is additionally used to prevent loosening.

If the cut ends are too "narrow", you will have to either put on a non-double bearing on each side, or bore the neck to a greater extent.

In the next video, you are waiting for the vortex cutting of the lead screw of the 16K20 lathe.

The comment was sent successfully.