All about inch taps

It is important to know everything about inch taps for every person who is going to engage in plumbing work in everyday life. 1/4 '' and 3/8 '' models are common, but other tap sizes are available. Separately, it should be said about tapered pipe taps and their designation.

Peculiarities

The threaded connection is characterized by increased reliability - everyone who has to work with metal does not doubt this. If necessary, it allows you to easily separate parts of the assembly. But for threading for bolts and nuts, special devices are used inside - inch taps. They are used on a par with metric ones and differ in a working angle of 55 degrees. Quantitatively, size is expressed in inches; the product itself is marked with the letter W.

Varieties

For tapered pipe taps, the thread size designation can take the form:

-

1/16;

-

1/8;

-

1/4;

-

K 1;

-

K 1 1/2;

-

K 2;

-

1/2;

-

3/8.

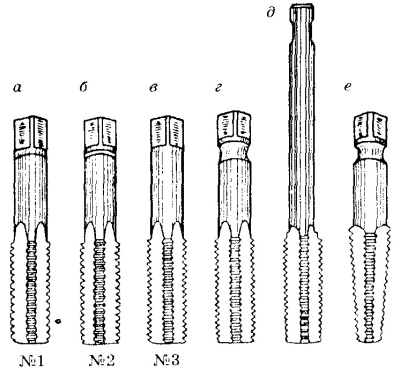

Various cutting equipment can be used for plumbing work. The manual device is widely demanded by locksmiths. It is suitable for the construction of blind and through holes. 2-set models are often used for marking. Choosing 3-piece versions is essential for cutting especially coarse threads.

The machine-manual type of taps is in demand. It is useful both for manual use and for mounting in machine tool chucks. If it is used in manual mode, cutting with a limited pitch is allowed. Machine-hand technique with 6 threads allows working with through holes. When machining blind holes, use equipment with 3 threads on the functional body.

There are also purely machine taps. They are equipped with screw or short grooves. This solution does not allow manual work. Sometimes nut taps are purchased. They have an elongated tail segment. A nut tap is used to work on a lathe or machining center.

The device got its name for its ability to work with several nuts at once. Periodic eversion is not required in this case. The nuts are threaded onto the tail piece one by one. As a result, the productivity of the work increases significantly.

All nut taps are single... Each of them has a working section with a dozen turns. In special machines for cutting hardware, such devices are installed only with a curved tail block. From such a support, the nuts will drop by themselves. No additional effort is required.

Inch taps - full featured replacement for metric taps... Their range of applications is the same. Such industrial tools are used in the USA, England and a number of English-speaking countries.

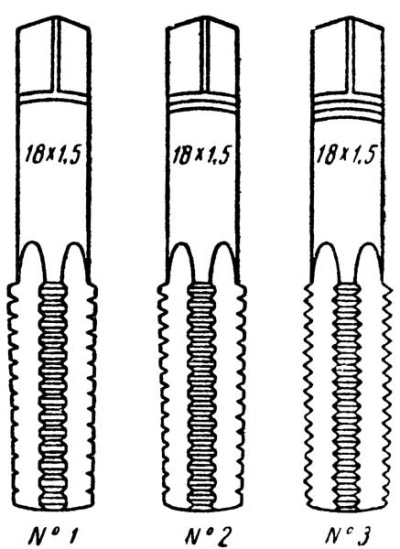

It will allow you to cut both blind and through channels in steel and cast iron products. Can be divided into 3 levels of accuracy.

There are more specific rifling options:

-

BSW;

-

UNF;

-

UNC;

-

8UN;

-

UNEF.

The tubular inch type stands out. It is customary to mark it with the letter G. There is a range of sizes, among which the prevailing sizes are 1/2, 3/4 and 1 inch. Pipe systems are available in manual and machine designs. Basically, these are two-component options with sharp or blunt approaches.

Top manufacturers

It is better to buy inch taps from the same companies that supply selected threading kits. We are talking about brands:

-

Berger;

-

Matrix Master;

-

Biber;

-

JTC;

-

Bovidix;

-

Rothenberger;

-

Hobby CS Bucovice.

Determination of the thread pitch

You should not trust the descriptions according to GOST. It is imperative to monitor the correctness of the indicators. Measurements should be the same for both inch and metric taps. The easiest way is to use fittings or couplings, the internal grooves of which were previously checked for compliance with GOST. The test is carried out by tightening the grooved bolt.

If the bolt forms a tight threaded connection, then the cross-section and thread pitch can be considered as corresponding to the template parameters. To measure the internal thread on the pipe, you must also use hardware with an external thread. A more accurate result is obtained by using a thread gauge. A positive result in this case will be its tight pressing.

Finally, the tap can also be examined with a vernier caliper; in this case, several grooves are measured to better represent the situation.

The comment was sent successfully.