All about the density of rubble

It is impossible to make concrete that can withstand high loads without crushed stone. Before concrete was obtained, the construction of multi-storey buildings remained difficult. The cost and characteristics of concrete depend on the parameters of crushed stone, including density.

What it is?

There are several types of rubble, but they are combined into primary and secondary. The first is obtained by crushing and crushing rocks, in particular, granite and basalt, the second - by crushing secondary raw materials (bricks and foam / gas blocks, old plaster, fragments of concrete structures and supports, asphalt, cement coatings).

Primary crushed stone is used in the construction of buildings and structures, secondary - in the construction of temporary and permanent roads. Both the one and the other type of crushed stone is characterized by density - specific gravity, measured in kilograms per cubic meter.

According to GOST, the true density is a material without air gaps, whose cubic meter weighs a certain amount of kilograms. Bulk - with air gaps left by loose stones. Gaps are caused by unevenness in the stone. For this purpose, craftsmen sometimes operate with the opposite concept - the coefficient of airing, which is the percentage of voids in the rubble. Sometimes it happens that much smaller stones spill out into the gaps left by large stones - this phenomenon is most often in the lower part of a heap of rubble transported or already poured out by a dump truck at the place of delivery. In this case, the bulk density reaches its maximum.

For crushed stone of a specific fraction, there is an average value determined by the same GOST. The smaller the fraction, the closer the bulk density value is to the real one.

So, for granite crushed stone, the true density is equal to the density of granite, for brick - the density of unbroken bricks, and so on. The density index is determined by the presence in a mineral of a specific amount (by weight and volume) of minerals that form the same granite.

Flakiness has some effect on the bulk density - the number of grains in the form of a needle or blade, which differ in shape from other pebbles. High-grade crushed stone reduces the bulk density and does not affect the absolute density in any way. Needle or wedge-shaped granules of crushed stone increase the amount of voids between stones of ordinary shape. The flakiness of individual batches of crushed stone produced from stone, which is mined even from the same granite layer, is individual. Low-grade crushed stone is more expensive than non-filtered crushed stone from sharpened granules.

Density of different rubble

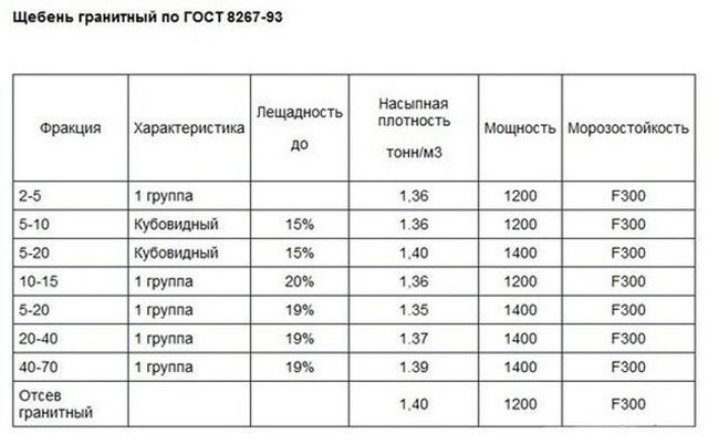

Granite (gravel) crushed stone is the most demanded and popular. The bulk specific gravity is 1.3-1.7 g / cm3. Fraction of granite crushed stone up to 5 mm refers to crushed stone screening. It, in turn, contains an increased amount of dust and sand residues - much more than the two percent specified in the GOST standards. Such building material is used when filling pedestrian zones, playgrounds and play fields. Particles 5-20 mm in size are an obligatory component of concrete for the foundation for a one-story private house, outbuildings in the courtyard and on the site.

Crushed stone of 20-40 mm fraction is an obligatory component of concrete for road-rail reinforced concrete bridges. They are subjected to a constant multi-ton dynamic load, which often takes on the nature of vibrations with a fairly high frequency - up to tens of vibrations per second.For the best performance, concrete is used with a variable fraction of 5-40 mm per pebble. The second application is filling parking lots for super-heavy special equipment, weighing more than one ton with an empty body of a moving unit.

Crushed stone 40-70 mm fraction - mainly rubble stone... It is used to create embankments for highways and railways. Compacted crushed stone with a variable fraction has a maximum bulk density of 1700 kg / m3.

Limestone crushed stone has only a small range of bulk density spread - from 1280 kg / m3, can add up to +50 kilograms per cubic meter in this value. Its advantage is environmental friendliness, the best frost resistance. It absorbs no more than 2.5% of water even with constant rains, and the amount of impurities can reach more than 10% of its mass.

Crushed slag lighter than water - its bulk specific weight is not more than 800 kg / m3. The strength characteristic is marked as follows: the average indicator varies within the M800-M1200 range, the increased one - in the M1400-M1600 range.

Rubble has a high density - sometimes almost higher than granite: from 1200 to 2800 kg / m3. Marble is one of the highest: up to 3000 kg / m3. It is very difficult to find crushed stone above 3 t / m3: only basalt, which is formed, for example, when drilling oil and gas wells up to 15 km deep, has such a density. The extraction of basalt rocks is an expensive undertaking, and basalt building materials (crushed stone, basalt wool and granules) are not cheap. The density of basalt is up to 3.1 t / m3, it is due to the significant depth of its occurrence in the earth's crust of the planet.

But the stones obtained from broken foam blocks, as well as expanded clay balls that have served their time, have a density of 250-600 kg / m3 and are much lighter than water.

The density of black crushed stone is approximately comparable to that of basalt - up to 3100 kg / m3. It is one of the most expensive - due to its density greater than 3 t / m3, which makes it possible to withstand a fracture pressure of up to 800 atmospheres.

By mixing the residues from the production of crushed stone of different types and varieties, a combined crushed stone is obtained. However, due to the different density, secondary (including primary residual) crushed stone is used with caution - mainly when arranging places, sites and roads where a perfectly flat (by the standards of an asphalt roadway) surface is not so important.

Determination methods

Determine the real - bulk and absolute - density of crushed stone is most reliable in a laboratory. For the user (customer), the most suitable way is to calculate by the scatter of values from the tablesusing an empty container such as a 1 liter glass jar. Knowing the weight of the can, it is easy to calculate what the bulk density of the crushed stone is.

Measuring vessel

The standard liter in this case is a 1 liter can. A mark is preliminarily applied to it, after seeing to what level a liter of water poured inside will rise in it. The water is drained, the jar is dried, and a volume of rubble is poured into it - so that on average its level crosses the mark. Let's consider further actions.

-

Due to the unevenness of the pebbles, the edges and edges of the most overlying ones can go beyond the line and rise above it. When measuring 1 dm3 of crushed stone, it is repeatedly shaken until the stones occupy the maximum volumetric space in this volume.

-

Then the jar is placed on an accurate scale (kitchen scales can be used). Subtract the weight of the can from the obtained value. The resulting difference is the bulk density of the crushed stone.

-

To calculate the real density, into a jar of dry rubble using a measuring cup (with factory marks) add water until its level covers (almost) all the pebbles, reaching the line. For example, in the voids left by 1 dm3 of crushed stone, it was possible to pour an ordinary glass of water (220 ml), which filled all the air gaps between the stones.

The resulting difference - in this case 780 ml - will turn out to be a useful (effective, real) volume of crushed stone (780 cm3 - from 1 dm3). Using the method of the main property of proportion (recalling the course of elementary mathematics for grade VI), we calculate the weight of 1 dm3 of real building material, the density of which is being measured at the moment.

Using a table

The quality of granite is judged from how far the resulting value of the density of crushed stone is from the density of granite - 2.7 g / cm3 (or 2.7 kg / dm3). Too different from the "granite" value of the absolute density suggests that the crushed stone is not made of granite at all, but, say, basalt or, in general, secondary. The fact is that some building materials have a color similar to granite - for example, crushed slate, recycled due to multiple cracking of sheets after decades of active and continuous operation. Slate, crushed into small pieces, outwardly resembles fine granite or its screening. GOST-9578 will help to deal with the density of crushed stone.

|

A kind of crushed stone |

"Granularity", mm |

How many kilograms fit in a cubic meter |

Brand M |

|

Granite crushed stone |

20-40 |

1370-1400 |

1100 |

|

40-70 |

1380-1400 |

||

|

70-250 |

1400 |

||

|

Limestone |

10-20 |

1250 |

|

|

20-40 |

1280 |

||

|

40-70 |

1330 |

||

|

Gravel |

0-5 |

1600 |

|

|

5-20 |

1430 |

||

|

40-100 |

1650 |

||

|

from 160 |

1730 |

||

|

Crushed slag |

arbitrary amount |

800 |

800 |

|

Expanded clay crushed stone |

20-40 |

210-340 |

200, 300 |

|

10-20 |

220-440 |

200, 300, 350, 400 |

|

|

5-10 |

270-450 |

250, 300, 350, 450 |

|

|

Secondary crushed stone |

1200-3000 |

1100 |

Do not underestimate the value of the bulk density parameter of construction crushed stone. Dilution of concrete is an ambiguous phenomenon: with an increase in bulk specific gravity, the amount of cement and sand decreases: it is physically impossible to fit into a cubic meter the initial amount of bulk building materials calculated for a larger stone. Reducing the amount of sand and cement while reducing the crushed stone fraction has a positive effect on purchasing and shipping costs.

The actual density of crushed stone can be up to two times greater than the bulk density - if the building material is not pre-compacted. Stones, whose fraction turned out to be too large, for example, from 120 mm in diameter, are additionally crushed on a stone crushing machine to the desired fraction.

This is what manufacturers do, destroying rocks with the help of explosives.

The comment was sent successfully.