Diy wood rocking chair

A rocking chair is a rather popular piece of furniture in the life of a modern person. It's so nice to relax in a comfortable chair on a day off, after a working week. The rocking motion of the chair will help you feel comfortable and calm.

However, the cost of such chairs often exceeds our capabilities, so many craftsmen prefer to make a rocking chair with their own hands. This is not as difficult as it might seem at first glance. One has only to prepare the necessary material and drawings, and you will become the happy owner of your own place for a pleasant pastime.

What do you need?

The most convenient material that can be purchased without undue effort in the store is wood. Wood products have a beautiful classic look, they are environmentally friendly and go well with any interior.

Conifers occupy a special place due to their low weight and density, which will be convenient in the manufacturing process.

You can give the product individual characteristics and any shape. So, for example, larch products are resistant to deformation, temperature fluctuations and moisture, they are not afraid of stress and damage, and, undoubtedly, they have an aesthetic appearance. But the most attractive still look products from elite wood species, such as ash or oak.

Having chosen the material, you need to prepare the tools. In order to build a rocking chair with your own hands, you will need:

- jigsaw;

- plane;

- Sander;

- milling cutter;

- level (preferably laser);

- several screwdrivers;

- construction pencil;

- tape measure for measuring the length of the material;

- clamp.

Features of drawings

Drawings for making a chair at home can be either come up with yourself or you can take ready-made ones. You must first decide on the desired dimensions and appearance of the chair. If you decide to make a drawing yourself, then for beginners you should take a chair as a basis, it has a fairly simple design, right angles.

Choosing a size

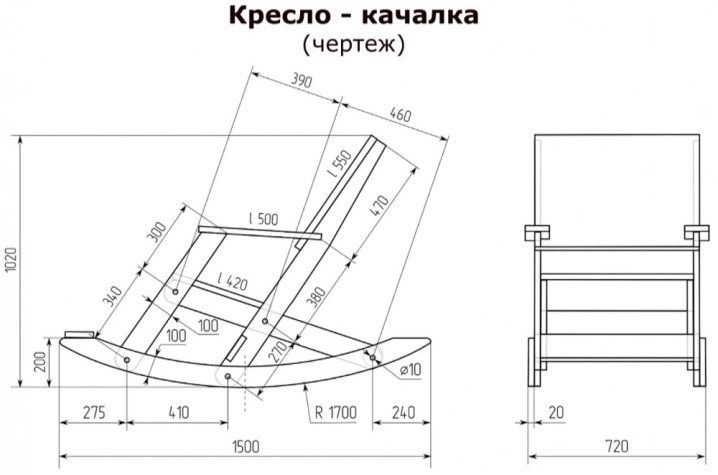

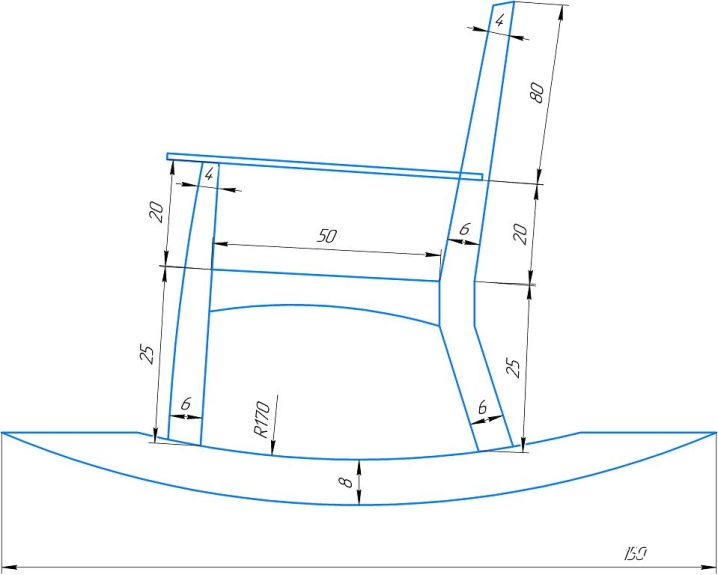

The dimensions of the rocking chair can vary depending on where you would like to use it. It is recommended to make garden ones a little wider than standard sizes, more compact ones will perfectly fit into the home interior. A standard chair based on an ordinary chair has the following dimensions:

- height - 1020 cm;

- width - 720 cm;

- the length of the product in cross-section is 1500 cm.

It is necessary to make a drawing of a square seat, measuring about 60 cm. The thickness of the seat can be taken approximately one and a half centimeters. For the legs, you will need bars with a height of about 110 cm, the height of the front legs is usually taken up to 60 cm.According to your preferences, these parameters may vary.

How to do it yourself?

Simple

The progress of making a simple chair should begin with the preparation of parts. According to the drawing, we cut out the seat, legs, back. The elements of the product are fastened with grooves and glue, which will allow them to better fit to each other.

Plywood runners

For the runners, it is recommended to use a plywood sheet with a thickness of about 1.5 cm. The workpieces are cut with a jigsaw. The length of a simple workpiece is 1 m. In the legs of the product, slots are cut out equal to the width of the original material. In our case - 1.5 cm, we take the depth of the slots about 10 cm.Further, we install the previously prepared runners in the slots. In the area where the runners fit, we drill a hole with a diameter of 2 cm. The recess must be lubricated, a spike is installed in it.

Block runners

We cut grooves in bars with a thickness of 4.5x4.5 cm. The ends of the legs must be adjusted to fit the grooves. The runner material is then placed in boiling water to make it more flexible. With the help of inventory, they give the runners the desired bend. After that it is necessary to allow the product to dry and install in the grooves, while gluing... For a better result, it is recommended to tighten the product in the place of gluing with rubber bands.

After the product is assembled according to your drawing, the surface can be sanded and treated with varnish or stain, which will increase the life of the chair. It should be remembered that to extend the service life of wooden structures, they must be treated with a pest control agent and an antifungal liquid... A water repellent treatment is also desirable.

If you plan to use the chair as garden furniture, then you should not use the upholstery.

Because even under a moisture-resistant material, mold may appear. It is better to make removable mini-mattresses. However, for the home, you can add individuality to the look of your chair with the help of foam rubber, padding polyester and upholstery fabric.

Wicker

The wicker rocking chair is distinguished by the complexity of the weaving of the back and seat. It is recommended to use a vine for braiding surfaces; it is made from young willow shoots, which have a small thickness. Such material tolerates moisture well, which is suitable for outdoor use as garden furniture.

For the frame, sufficiently rigid structural elements should be used, for example, larger rods.

On the frame, it is necessary to fix the vine with the first layer along the perimeter of the product at a short distance. After that, the second layer should be fixed in a checkerboard pattern. In addition to the seats and backrests, the legs of the product can be intertwined. It should be understood that weaving is a rather complicated process that requires certain skills, therefore, for a beginner, this is not the most suitable option.

Other options

The easiest option for a garden rocking chair is to make it from a cable reel. It should be disassembled, then cut out in the circles grooves for the back and seat. Carefully glue the joints or fasten them with fasteners. This way, you get a small garden chair without too much difficulty.

Products made from metal rods are difficult to manufacture; certain skills in welding structures are required here. It is more convenient to weld products from rods to each other than products from pipes, since at the welding points the contact area of the pipes will be minimal, which can affect the service life of the structure. There are also certain difficulties in bending the runners; this will require additional equipment.

Such a product will have a fairly impressive weight, so metal armchairs are made quite rarely.

Recommendations

It is recommended to construct cross bars to balance the chair. So, if the product has a greater inclination forward, then the strips are mounted on the back. When tilted backwards, the counterweight is mounted at the front, which in turn can be used as a footrest.

If you decide to make a chair with your own hands, then pay attention to the choice of material, because at home it is quite difficult to make a suitable metal product. but building a rocking chair made of wood or plywood will not be difficult even for a beginner... And to add beauty to your own product, you can make patterns, sew removable capes or attach various decorative elements.

In the next video, you can watch the process of creating a rocking chair.

Cool, especially the video, thanks!

The comment was sent successfully.