DIY rocking chair

A rocking chair is a piece of furniture that always adds coziness to any interior. Despite a sufficient number of models on the market, it is much more convenient to make a rocking chair yourself, endowing it with individuality and maximum comfort for a specific situation.

Choosing a material

The choice of the material from which the rocking chair is made depends not only on your own preferences, but also on the conditions in which the furniture is to be used. Quite popular is the wrought-iron chair, which is assembled from metal rods and strips. This model is brought to life not only by forging, but also by conventional welding. A wrought-iron armchair is most often installed on the street, porch or spacious terrace. The material used is characterized by increased strength and long service life, in addition, it is not exposed to the negative effects of weather conditions.

However, there is metal chairs have a number of disadvantages... They weigh too much, and therefore do not differ in any mobility. Manufacturing will be impossible without special equipment. Finally, for some people, forged designs do not seem comfortable at all. In this case, you will have to additionally buy a soft mattress and armrests.

There is also an option for making a rocking chair from a plywood board. This option is the simplest and most budgetary, available for implementation by any person with basic carpentry skills. The advantage of this design is its low weight and the ability to bring any ideas to life due to the linear dimensions of the plates and their differing thicknesses. To extend the service life of the plywood rocking chair, additional processing is required using a polymer emulsion or acrylic-based varnish.

Wooden furniture is a fairly traditional option., which looks appropriate both on the street and in any interior. The wood itself is an environmentally friendly product that is easy to process and inexpensive. However, in comparison with the same plywood, the service life of such a chair will be longer. A chair made of profile pipes can serve for many years, including in conditions of constant stay on the street.

It is better to choose parts with an elliptical section and do not forget about the need to use a welding machine with a pipe bender. The finished structure must be covered with paint or varnish with anti-corrosion properties. To make the rocking chair convenient to use, you will need to make the seat and armrests from a board or plywood, and then cover them with fabric or leather.

A rocking chair made of polypropylene pipes looks pretty creativebut not suitable for home use. Since the material is characterized by increased resistance to weather conditions, it can be used outdoors, putting it indoors during frosts and hiding it from direct sunlight. Separate parts of the structure are assembled using a soldering iron. The more connectors are used, the more stable the chair will be.

Willow vine rocking chair looks very beautiful, but rather difficult to manufacture without certain weaving skills.However, the result is a lightweight and comfortable design that can be operated both indoors and outdoors. It will also be possible to weave a rocking chair from bamboo, rattan or reed. Furniture made from a cable reel turns out to be very unusual. This element is disassembled, after which a groove for the boards is cut in the circles, and the rods are rearranged under the soft seat.

Some craftsmen use an old chair with runners on the legs. In such current styles as Scandinavian or eclectic, rocking chairs, connected using the macrame technique, are often found. Furniture is also assembled from pallets, polypropylene pipes, plastic pipes or PVC pipes. When choosing a material for manufacturing, several aspects should be considered. From wood, it is recommended to give preference to dense species, for example, oak, ash or larch.

Plywood should be taken of the "euro" type, with a thickness of up to 30 millimeters. Soft upholstery for outdoor use should still be made of moisture-resistant material and must be removable to avoid mold.

Determining the model of a rocking chair

There are a sufficient number of types of rocking chairs, it is better to decide on a specific model even before starting the development of the drawing. The easiest way is to create rockers on simple radius runners, for example, arcs or skis. They do not look too sophisticated for a city apartment, but they are perfect for a summer cottage or a veranda of a garden house. A feature of the rockers on the radii is their low fit, which prevents overturning. When using runners of variable curvature, overturning can be completely eliminated. Such models are suitable for people of different physiques, and sometimes they are designed together with the cradle, allowing the mother to rest with the baby.

Rocking chairs can also be made on elliptical runners or leaf springs. These models are often called nirvana chairs due to the creation of a very smooth rocking motion. Leaf springs are always made of high quality wood or spring steel, but they are not easy to use. Elliptical models are more comfortable, especially with bumpers. Of great interest is the "3 in 1" rocking chair, which directly combines a rocking chair, a lounger and a chair.

Although the multifunctionality of the model has many advantages, such a chair cannot always be used in apartments due to its large dimensions.

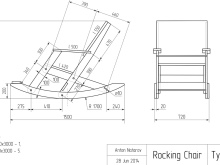

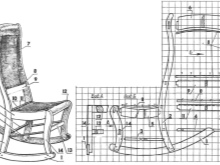

Making drawings

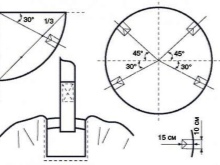

Despite the fact that there are a large number of ready-made drawings on the network, it should be remembered that they are designed for the size of specific people, and therefore they may not fit most users. To make a comfortable rocking chair, it is better to calculate all the indicators yourself and, based on them, draw up a diagram based on a sample. Beforehand, it is important to study the kinematics and understand how to make the rocking chair stable and comfortable.

The most important thing is to place the center of gravity of the seated person relative to the center of the resulting circle, since when these two points coincide, the chair does not swing at all. When the center of gravity is higher than the center of the circle, the stability of the chair is lost.

If several people are going to use the chair, then it is better to design a piece of furniture for the heaviest member of the family.

How to do it at home?

Making a rocking chair with your own hands will still be possible for those people who have the basic skills of carpentry or welding, depending on the chosen master class.

On runners

The easiest way to make a homemade cantilever chair is from a regular old chair or chair. In fact, all that remains is to add the runners themselves, securely fix them on the legs and, possibly, sew the cover. In addition to the legged chair itself, you will need runners, a screwdriver, screws, a drill and sandpaper. To give the rocking chair an aesthetic look, paint with a brush is useful.The runners themselves are cut independently in shape using a pattern, or they are ordered from the master.

It is important that the gap between the legs is less than the length of the runners by 20-30 centimeters. In those points where the chair is fixed on the legs, holes are drilled, after which the runners are “tried on”. If the result is positive, the latter can be sanded with sandpaper and painted over in several layers. The finished "skis" are put on the legs and fixed with screws in the already prepared holes.

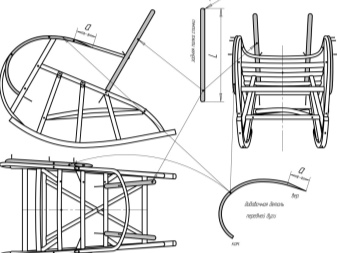

Pendulum

An excellent pendulum rocking chair is obtained on the basis of bearings. The compact and robust design provides even sway and is ideal for outdoor use. For manufacturing, it is necessary to prepare two steel strips with dimensions of 40 by 4 millimeters and 60 by 6 millimeters, as well as profile pipes with dimensions of 20 by 20 millimeters and with a two-millimeter wall thickness. The movement of the rocking chair can be provided by 8 bearings, the outer diameter of which is 32 millimeters, and the inner indicator is 12 millimeters, as well as 8 bearing cages. They are created with their own hands on a lathe, or they are cut from a tube. Finally, you can't do without a pair of garage hinges and M12 bolts and nuts.

In order to minimize welding, the profile pipes can simply be bent using a homemade jig. In order not to make mistakes, it is better to apply markings every 100 millimeters beforehand. The entire frame of the rocking chair is made from the profile pipe, that is, the support part, two sidewalls, a seat and a back. As a rule, for a standard size of outdoor furniture, it takes about 20 meters. From the strip and the profile, details are created that regulate how much the back of the chair is tilted in the amount of 2 pieces.

A steel strip measuring 6 by 60 millimeters is cut into two equal parts. From it, as well as bearings and bolts with nuts, pendulums in the amount of 4 pieces are created.

It is important to keep track of the distance between the centers of the bearings equal to 260 millimeters. At the end of the work, all finished parts are assembled into a single structure.

On springs

It is not recommended to do a spring rocking chair with your own hands, since this mechanism is very complicated in execution. The design has a strong and fixed base, above which is a large spring. It is she who is responsible for rocking the soft seat mounted on top. It is much easier to make a hanging rocking chair, which will decorate both the summer cottage and the children's room.

A homemade swing is easiest to make from a hoop with a diameter of 90 centimeters, a piece of dense fabric with dimensions of 3 by 1.5 meters, non-woven fabric, 4 metal buckles, 8 slings and a metal ring, for which the chair itself will be suspended.

The hoop is either created independently, or it is formed from a metal-plastic tube or bending wood. First of all, a pair of equal squares with sides of 1.5 meters is formed from 3 meters of fabric. Each of them is folded 4 times, after which a circle with a radius of 65 centimeters is cut out of the workpiece. On the blanks, the inner contour and the holes for the lines are marked.

Having spread out both circles, it is necessary to iron them and make all the necessary cuts, gluing the "petals" inside out with the help of interlining. The full slot is sewn along the edge with a 3 cm deviation.

In the next step, both workpieces are sewn together, leaving a hole for the frame. The remaining free allowance is cut with teeth, after which the finished cover is turned inside out and ironed again. The hoop itself is sheathed with the selected filler, cut into strips with a width of 6 to 8 centimeters. The frame is inserted into the cover, both parts are connected to each other. The cover is filled with padding polyester strips, sewn to the fabric with a blind seam. The sling is cut into 4 2-meter pieces, the edges of which are melted on both sides.The slings are pulled through the recipes and sewn several times. Buckles at the free ends will allow you to adjust the height and tilt of the rocking chair. All slings are assembled and fixed on a metal ring.

How to make a hammock chair from a metal hoop is described below.

The comment was sent successfully.