How to make a plywood rocking chair with your own hands?

Having conceived to make furniture with their own hands, people are often puzzled by the question of the selection of material. If you did not have practical skills in creating pieces of furniture before, you should start with the easiest materials to use, in particular plywood. In addition, there is no need to start experimenting with heavy and highly complex pieces of furniture. At first, try making a small plywood rocking chair for your nursery, guest room, or bedroom.

What do you need for manufacturing?

To make a rocking chair on your own, you should stock up on the following:

- plywood sheets;

- a bar of wood (53 centimeters long);

- angle grinder or electric jigsaw;

- a set of saws for wood (saw blades from 50 to 105 millimeters long);

- a manual electric milling cutter or a disc grinder with abrasive wheels having different grain sizes (you can use a simple sandpaper);

- tape measure and pencil;

- electric drill with wood drills;

- self-tapping screws, nuts, washers;

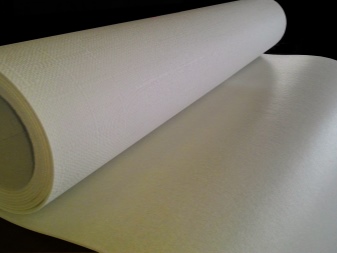

- padding polyester;

- dense fabric for drapery;

- glue, stapler for furniture;

- paint on wood, varnish.

To create the rocking elements, it is advisable to use plywood sheets with a size of 1520 × 900 centimeters and a cross section of 4.10 and 15 millimeters.

The sides require 4mm plywood. If the necessary sheets are not available, then it will be possible to cut out a number of similar elements from thin material in the course of work and connect them with glue.

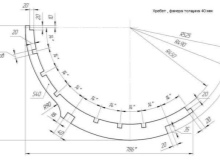

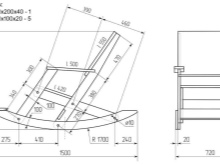

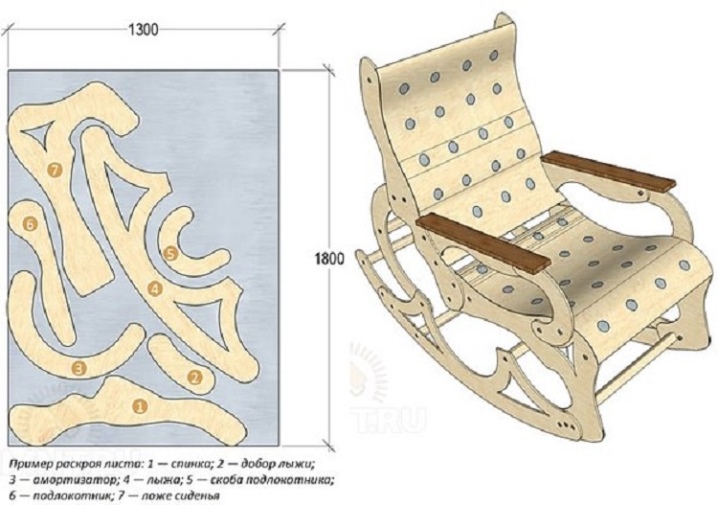

Drawings and dimensions

Before you start making furniture, you need to create a drawing of a plywood rocking chair. You can draw a diagram with parameters by hand, make a drawing using specialized computer programs, or choose any ready-made drawing, modifying it as you like. The presence of a drawing drawn up in accordance with all the rules not only speeds up the procedure for cutting and assembling the material, but also eliminates errors in the manufacturing process.

Progress

Creating furniture items from plywood is practically the same as creating chairs from other panel materials.

The procedure includes several stages.

All of them are carried out in the following sequence:

- preparation of elements - chamfering, drilling holes, creating grooves and much more;

- transfer of the drawing;

- cutting material according to the selected drawing;

- assembly of the chair;

- finishing, including sanding and painting, as well as drapery.

Let's consider the listed activities in all details.

Plywood preparation

Initially, you should rationally organize your workspace. When cutting large plywood sheets, there should be enough room in the room.

To prevent quick wear of the chair components, it is required to cover the material with any of the following means:

- fiberglass material;

- varnish;

- drying oil;

- paint.

Pasting with fiberglass material extends the life of the plywood. If this coating is not possible, you can take a simple gauze cloth instead.

To connect the materials, a varnish is used that does not contain epoxy and polyester resins in its structure.

The varnished coating protects the plywood from the influence of environmental factors. Improving moisture resistance will allow coating with paint or drying oil, which will form a waterproof layer (the protective composition will be more practical if you first warm it up in a water bath to 60 ° C).

Close attention is required to be paid to the end edges of the plywood elements. They need additional protective coating and thorough treatment. To protect them, you need to do any of the following:

- seal the ends of the plywood with putty;

- cover with a deep penetration primer;

- use thick-grated oil paints;

- glue the edges with plastic or metal edging.

When working with plywood, you need to adhere to these recommendations.

- Do not cut the plywood across its fibers - this will provoke cracking at the edges of the sheet.

- It is advisable not to hammer nails into the plywood sheet and not to screw self-tapping screws, since this can also provoke the appearance of cracks on the surface. To prevent this, the holes must first be prepared. In the event that, nevertheless, the plywood elements are connected with self-tapping screws, it is necessary to put metal washers on them.

- In order for the plywood to acquire the required bend or configuration, its surface must be moistened and left in this state for some time.

- Before gluing plywood elements, their adjoining parts need to be sanded with sandpaper, then dust is removed from the parts and glue is applied in the direction of the material fibers. The elements to be glued must be placed under the press.

Transferring a drawing

After you have navigated the selection of the drawing, it remains only to plan the sheet according to it. In other words, it is necessary to transfer the paper drawing to the material, while increasing the scale of the drawing to the natural parameters. If the structure of the furniture that needs to be assembled has a simple configuration, the image from the paper is transferred along a curved square and a ruler.

When it is planned to manufacture furniture with a complex configuration, templates (patterns) are cut out for each element from cardboard or thick paper, which are then traced on a plywood sheet, as in the image below.

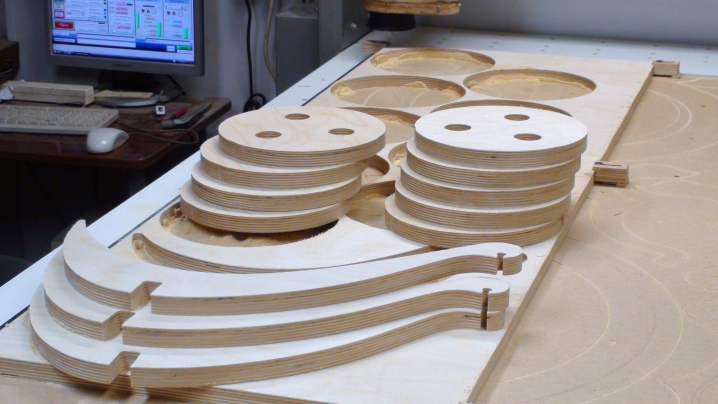

Sawing

Since plywood has a varied cross-sectional size, then for cutting a sheet of a certain thickness, a toolkit that meets its purpose is taken. Sheets up to 1.5 millimeters thick are cut with a sharpened knife. Sheets up to 6 millimeters - with a hand jigsaw, and thicker - with an electric jigsaw or an angle grinder.

For making curved cuts, it is better to use an electric jigsaw, since this tool is the most affordable.

If possible, the elements are cut with a band saw, if only a fine-toothed blade is used.

To make it convenient to cut, we glue the pattern directly onto the plywood sheet.

After the elements were cut out, we put them together and examine the coincidence of the contours; if there are protrusions, we immediately align them.

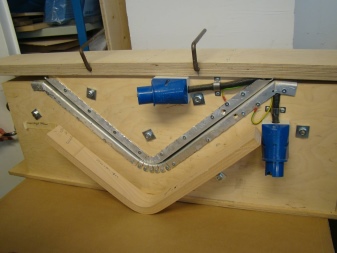

Assembly

The first step is to assemble the seat and back support from thin strips of 10 mm thick wood. These strips must be glued to the seat and backrest elements cut from 4 mm plywood. This structure allows for a curved configuration. It is desirable to glue the elements with moisture-resistant PVA wood glue.

Then the crossbars are mounted to the seat base and the back support, followed by the side elements and the footrest. When installing the elements with self-tapping screws, it is necessary to install iron washers.

After completing the assembly work, you can start giving the finished look to the plywood chair. Everything here depends on the area of its use. If pieces of furniture are made for outdoor use, they should be treated with antiseptic agents and painted.If the product will be in the living room near the fireplace, it should be given a more respectable appearance. For this, the chair can be draped with a leather substitute or velor. The drapery should be nailed to the frame with small nails or with a furniture stapler, starting from the back.

If you don't feel like doing the laborious work of draping the chair, you can sew a removable cover on it. For this, a strong and pleasant tactile material and foam rubber are used.

Making a rocking chair out of plywood is quite simple. It goes without saying that the conversation is about extremely ingenuous designs. The most labor-intensive models will require much more labor and costs. But such a rocking chair, a practical guide for the construction of which is given above, if desired, can be made in just one day.

How to make a rocking chair out of plywood, see below.

The comment was sent successfully.