All about adirondack chairs

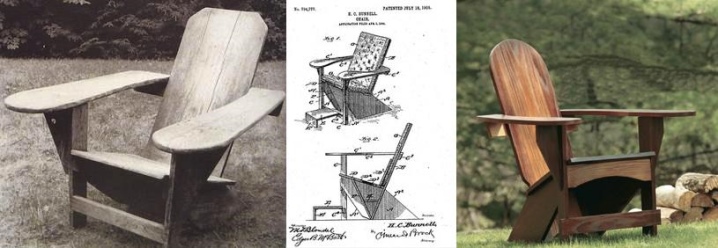

The renowned Adirondack recliner chair has a long and fascinating success story. Despite the fact that the product got its name from the place of invention, it owes its wide distribution to one person, about whom few people know.

Nevertheless, the armchair even has its own museum - not every piece of furniture can boast of this. What is the secret of the relentless popularity of this model?

What it is?

At one glance at the Adirondack, all thoughts are carried away to rest. It just has to sit down, lean back on a comfortable back and stretch your legs... Any model of this chair is amazingly comfortable, it can be put on any kind of relief, and it will be stable.

The model is equipped with wide armrests, so you can put mugs or a tray of plates on it, or put a book on it. Some chairs have special wooden coasters, with the help of which they become folding sun loungers.

It is fair to say that the adirondack is designed in such a way that a person sitting in it can relax all muscles and rest properly.

The armchair seems very simple, uncomplicated in style, design and construction. And indeed it is. Nevertheless, the Adirondack is so versatile that it can be appropriate in almost any recreation area - in the mountains, on the beach, on the hills, in a park among trees, near any body of water, it does not matter, natural or artificial. It is comfortable for everyone - for a respectable old man, for a child, for a young lady, and for a mature lady. On these chairs, you can comfortably carry on a conversation or enjoy contemplative solitude.

In short, the Adirondack is a case of genius hiding in simplicity.

History of origin

The Adirondack Museum is located in the mountains of the same name. They are on the Canadian-American border. Interestingly, the chair was originally called "Westport" - this was the name of the town where the inventor of the model lived.

The one who came up with this amazingly comfortable leisure product, name was Thomas Lee. It happened at the very beginning of the 20th century. But even today, adirondacks can be found at recreation centers, and in gardens, and in parks, and on beaches. And all because of the ingenious simplicity of this product. In order to create it, you only need boards and a few nails. This chair looks good both indoors and outdoors.

Upon completion of his work, Thomas Lee asked his loved ones for their opinion on its result. All as one approved the product. Further, the master received a patent for the "Adirondack" chair (it happened in 1904), after which numerous variations on the theme of the original product began.

Now there is not only a classic chair made of wooden slats with large and wide armrests and a backrest located at the most comfortable angle, but also a model for two, divided by an armrest-table, and a chaise longue with a footrest, and much more.

Tools and materials

As stated, the American-style Adirondack model is simple. All that is required to make a chair with your own hands is lumber (what they will be, everyone decides for himself), a few nails and screws.

It is worth considering that wood is susceptible to the effects of fungus, mold, precipitation and fire, therefore, each element of it must be treated with an antiseptic and covered with a protective varnish or paint.

Craftsmen will even use slats made of wooden pallets and pallets - a decent adirondack can be made from such material.

If we talk about tools, then their minimum is as follows: the presence of a jigsaw, a screwdriver and a hand sanding bar. If you want the work to move faster, then it is better to have a band saw, an edge router and a sander at hand. And when a hard type of wood is chosen for work, you need to get a finger mill. Without these tools, the work will be long, because the parts need to be processed with high quality.

Be sure to consider how much does the material weigh, after all, it does not matter whether a folding or a monolithic chair of this model, in any case, it must be mobile enough so that it can be moved from one place to another.

If the adirondack is too heavy, it will be difficult to move it, which means that its very essence - to allow the owner to rest in comfort in any beautiful place - will be disrupted.

Drawings and dimensions

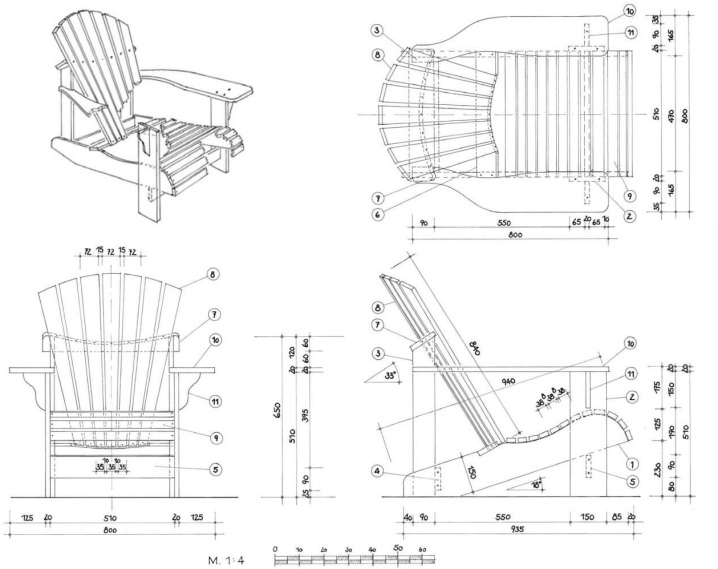

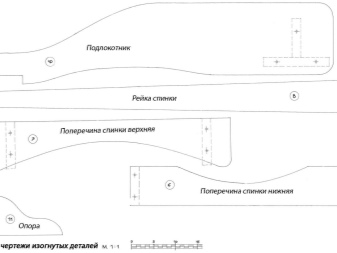

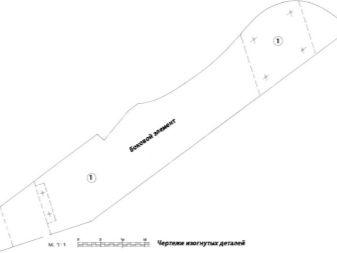

Before starting work, it is necessary to draw up a diagram (drawing). Each detail should be drawn on it - a side support in the form of a template (scale 1: 1), and you also need to make patterns for the upper guide of the chair back, the lower transverse strip of the back, an armrest and an emphasis for it, seven slats of the back and eight slats of the seat, legs - front and back. All patterns are made of paper. Each measurement is made in centimeters.

As soon as the drawing is finished, every detail needs to be projected onto the corresponding workpiece.

At this stage, you do not need to be very precise when applying rounded elements, but the dimensions must be consistent.

Manufacturing scheme

Details are marked strictly in accordance with the drawing. To make a markup, you will need a square and a tape measure. In areas with curved lines, you will need a 1-meter stainless steel ruler.

Boards or slats, backrests used for seating should be thinner than the wood from which the supporting parts are made.

All paired parts are made using the mirror method. The same template is used for this.

Cut out the details

The stage of work, called the cutting of parts, begins with the formation of elements that have a rectangular shape. Cutting is carried out using a jigsaw or a band saw, in accordance with the dimensions of the parts indicated in the drawing. The drawing should have a scale of 1: 1, that is, it should contain the dimensions of the parts in full size.

Before you start cutting out the parts, they must be checked against the dimensions in the drawing. Bevels are best cut with a plunge saw.

Grinding

It is necessary that the edge on each part be ground and rounded using a manual or mechanical method. To make it more convenient grinding of paired elements is carried out simultaneously. The surface of each part is also polished. The process is completed with P-180 abrasive.

To make the work go faster, the parts are pasted over with masking tape, on which the markings are applied.

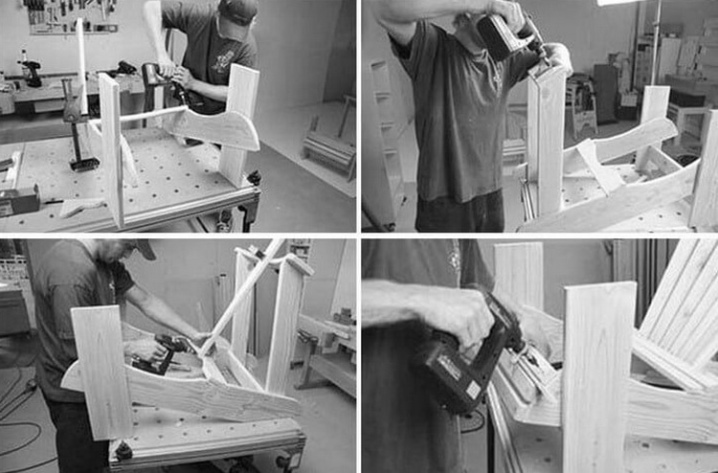

Assembly

Before assembling the chair, all its wooden parts must be treated with an antiseptic (from decay and fungal infection). After the antiseptic composition has dried, the wood is varnished or painted over wood, thus creating an additional protective layer.

The chair is assembled with self-tapping screws (previously, nails were used, but today the process has been modernized). Self-tapping screws should have a size of 3.5 x 35 mm, they need about 70 pieces. Holes are required for fasteners, they need to be drilled with a countersink. The diameter of the countersink is equal to the thickness of the screw. Since the Adirondack is furniture, the fasteners for it must be used with an anti-corrosion coating. They can be made from stainless steel or hot-dip galvanized steel.If the self-tapping screw is made of ordinary steel, then it will become covered with rust over time, and dark spots will appear on the slats, after which they will begin to collapse.

The step-by-step assembly instructions are as follows: first assemble the base of the chair. To do this, the side elements are connected to the legs of the product - front and rear. After that, the cross members and the head cross member are installed.

After assembling the base, you should proceed to the back. Each rail must be screwed in, observing the intervals indicated in the drawing. Then screw each seat rail. The spacing between the slats is 8 mm. The places where the supports will be located must be marked and secured. The last step is to install the armrests and fix them on self-tapping screws.

Rounding the backrest slats

Any modification of the Adirondack has a rounded upper back... This is a characteristic feature of the chair. In order for the rounding of the slats to be accurate and symmetrical, you need to proceed as follows: in the area of the center of the extreme slat of the seat, you need to fasten the string and fix the pen, pencil or felt-tip pen.

After choosing the desired radius, you should mark the slats in a semicircle. Next, using a jigsaw, you need to grind the edge of each of the cuts.

The comment was sent successfully.