Choosing an electric spray gun

Electric spray guns are chosen to provide adequate coating quality. From the material of this article, you will learn what such a technique is, what it happens, what advantages and disadvantages it has. In addition, we will provide a brief overview of the best models, tell you about the nuances of choosing and using a classic unit.

Features, pros and cons

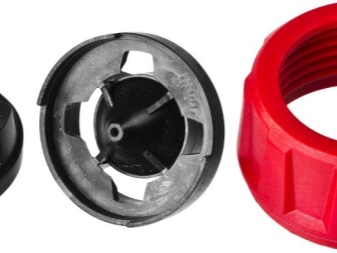

Spray guns have a simple design. The device has a nozzle, a tank, a housing with a built-in electromagnetic pump, a handle and a power cable. The distribution of the coloring matter is carried out by the incoming air.

The spray gun tank can be plastic or aluminum. The built-in piston, packed in a cylindrical body, is responsible for sucking and ejecting the mixture. The device also includes an electromagnet, an oscillating bar and a valve that opens and closes the material supply.

The principle of operation is to convert electricity into pneumatic. A jet of paint and varnish material is supplied from the container under pressure. Thanks to the nozzle, it is atomized. Then the paint goes to the surface to be treated.

Oftentimes, an electric spray gun does not have a massive compressor. This makes it easy to use. However, due to the lack of a compressor, the list of possible materials used is reduced.

In addition, the devices cannot apply thin layers of paint.

On rare models with a built-in mini-compressor, the quality of the jet is better. Like many analogues, they do not leave paint fog. Electric spray guns have a lot of undeniable advantages. They are used in household and professional spheres.

They perfectly replace manual labor, do not leave streaks, bald spots, bristle residues, as is the case when using ordinary brushes or paint rollers... Provide uniform coloring of areas of different sizes.

Versatile, mobile, differ in the principle of work... With their help, surfaces of different types are painted in different positions. They are used for painting vertical, horizontal, inclined bases, ceilings, figures of varying degrees of complexity.

They are used for painting the facades of houses, for interior decoration of residential and non-residential premises.... They have proven themselves well when painting gates, cars.

They have an affordable cost, optimal functionality. The devices are easy to use, save time and physical strength for painting different surfaces. They have different nozzle diameters.

However, the devices are difficult to clean. It is rather difficult to rinse them after work. In addition, other varieties are not intended for water-based, silicate materials.

Views

Devices can be classified according to various criteria. According to the type of pressure, they are divided into 3 groups: low, medium and high. The first line includes products with pressures up to 3 atmospheres. In the second - up to 10, in the third - 10-55.

Models differ in the principle of liquid spraying. For example, electric spray guns marked HP are high pressure equipment with a high speed of paint spraying.

Varieties marked MR - models with medium pressure values. LVMP - marking of medium pressure nozzles that use a little material. NTE, on the contrary, it indicates that the device consumes a lot of paint.

Based on the principle of operation, electric spray guns are air and airless. Each type of product has its own characteristics.

Air

Depending on the design, air-type devices are equipped with an upper, lower or specialized pump. The distribution of the coloring matter is related to the design of the product.

The principle of operation is similar to pneumatic models. After being fed into the nozzle, the pigmented composition crumbles into dispersed dust due to air. However, the method for obtaining airflow is different.

Electric paint sprayers use a solenoid or turbine electric motor. Based on the power of the blower, it can be built-in or free-standing.

Such devices are selected taking into account the power needs. Due to the absence of a receiver, the operation of the electric motor is constant. Besides, the devices work noisily, the sound is comparable to the work of a classic vacuum cleaner.

In general, such spray guns are reliable and durable in operation. Easy to assemble, disassemble, maintain. Depending on the model, they have increased productivity, adjustment of the mixture supply and the width of the torch. They have a guarantee and instructions in Russian.

They save the used dye, minimize its loss when dyeing any substrates. They function without vibrations, are ergonomic and compact. However, they may have a leaky tank lid.

These varieties paint surfaces with a high quality with a loose layer, but unlike other modifications, they form a colorful fog. Therefore, when using technology, you have to use protective equipment.

Most often purchased by home craftsmen. They have an average weight of 1400-2500 g, a built-in tank capacity of 1 liter, they consume 350 ml of paint per minute. Supplied with a variety of attachments. In terms of quality of work, they are inferior to pneumatic counterparts.

Airless

An electric spray gun of this group sprays paint by means of high pressure (500 atmospheres versus 8 for air analogues). It works at the expense of a plunger piston pump, it is effective in working with particularly viscous materials.

When coloring, no coloring cloud is formed. However, the correct nozzle must be selected before painting. Otherwise, drips, sagging, unevenness of the layer cannot be avoided.

These modifications are compatible with a wide range of materials used. They perfectly distribute various dyes, car varnishes, priming solutions on the surface. They work with stains and oils. The consistency of substances can be different.

They save consumables and are equipped with a reservoir that can hold 800-1000 ml of liquid. In a minute, they are able to consume from 300 ml of paint, which, based on the variety, can be consumed from the container using the hose used.

Plunger-type spray guns are convenient in operation and have an optimal cost. However, when spraying, larger paint particles are formed than those of the pneumatic type.

Because of this, the devices have a higher consumption of the dye. Some units are demanding on the viscosity of the materials used. Too thick dye clogs the nozzle. They are rarely used in industrial work.

Type of food

By the way they work, electric spray guns are stationary and rechargeable. Chain varieties make up the bulk of the assortment put on the market.

They have different cardinality depending on the type of tasks. Their service life is limited by the capabilities of the electric motor. However, spray guns cannot work without a generator in places where there is no central power supply.

Top Models

Many leading manufacturers have models that are the best in terms of practicality, comfort, cost and other parameters. The rating of the best products includes products of various brands.

- Wagner W 550 - a turbine spray gun with the European quality mark Perfect Spray.It is connected to a 220 V network, weighs 1300 g. It is considered one of the best and most reliable air devices with a high-quality coating of the processed surface.

Works with enamels, priming solutions, paints and varnishes, stains. It processes a surface of about 5 m2 in 12 minutes. The classic household option for the home. Not suitable for work with water-based emulsion, facade paints.

- "Zubr" ZKPE 350 - Chinese air spray for paint and optimally viscous varnish (for example, varnish). Perfectly sprays compounds based on latex, enamels, oils.

Has sufficient performance for household use. Saves material used, has minimal paint loss values. Does not make noise or vibrate during operation. The only drawback is the short cord.

- Ryobi P 620 - hand-held paint sprayer, battery-powered. Mobile, intended for interior painting of walls and other interior decoration. Equipped with a movable nozzle, thanks to which it can spray the colorant vertically, horizontally, circularly.

Purchased to work with different materials. It is in demand due to its compactness, mobility, and low weight.

Autonomous, refers to devices of the universal type. Has optimal technical characteristics.

- Bosch PFS 1000 - airless spray gun of a renowned manufacturer for covering small surfaces. Thanks to Bosch Spray Control technology, there is no unnecessary paint loss.

Easy to operate, economical to operate, has a low price. Suitable for painting wood, metal surfaces. It has 2 drawbacks: it is not equipped with material flow control and can work intermittently when tilted back.

- Intertool DT-5060 - airless paint sprayer for processing concrete, brick, metal substrates, operating from a 220 V network. Equipped with a flexible hose, it perfectly sprays many types of liquids (paint, primer and others).

Thanks to the HVLP system, it qualitatively and evenly covers the working surfaces without wasting consumables. It is purchased at a low cost, has no vibrations. Equipped with a shoulder strap, aluminum reservoir.

Not intended for painting surfaces with materials with abrasive suspensions.

- Sturm SG9645B - airless paint spray gun for painting surfaces inside and outside buildings. Designed to work with materials of different consistency, including lime and water-chalk based products.

Spends 320 ml of solution per minute, distributes the paint over the surface with high quality. Has a reservoir with a capacity of 0.6 l, provides circular, vertical and horizontal painting.

- "Energomash KP-9660R" - model of the leading manufacturer with a tank capacity of 0.7 liters. The position of the tank is lower, there is a manual adjustment of the material flow and the spray power, as well as protection against pollution, dust, moisture.

Shoulder strap included. Distinctive features of the device are smooth material flow, small size, and accurate paint distribution. Cons - the lack of a spare tank and the heating of the case during long-term operation.

- Fubag EasyPaint S500 / 1.8 - a network model for painting walls inside and outside, as well as garages. Has a power of 600 W, has an air principle of operation. It has a capacity of 0.27 liters per minute and is equipped with a half-liter tank.

Weighs 2.5 kg, works with materials with a viscosity of 20 din. It does not have filters, but it saves paint and varnish consumption and is compact. It stands out for its low noise level during painting.

- ELITECH KE 800P - powerful (800 W) air nebulizer with a capacity of 900 ml per minute. It has a tank volume of 800 ml, weighs 2.7 kg, and is used for spraying paint compositions on interior and exterior walls.

Designed for thick materials, has a viscosity limit of 80 din.Equipped with a carrying strap, it is characterized by a uniform coverage of the bases, and is economical in using the liquid used. The only drawback is the incomplete production of material from the tank.

How to choose?

To choose a quality and practical electric paint sprayer model for home or professional use, you need to consider a number of factors.

It is necessary to make a start from the manufacturer, price, body materials, nodal elements. In addition, weight nuances are the dimensions of the product, its weight, and user friendliness.

When choosing between reliable suppliers, you should look closely to manufacturers with a proven reputation and reviews left about brands by real buyers. The brands Wagner, Bosch, Zubr, Stavr, Sturm, as well as previously described companies stand out from a wide list of trademarks.

Choosing the type of food, they take into account their own preferences. Variants of the network type are volatile, but can work an order of magnitude longer than analogs on batteries. If this option is chosen, pay attention to the length of the cable (the longer it is, the better).

Battery models are more convenient to use, but their power is much less. On average, they can spray paint for no more than 30 minutes. They are often heavier due to the batteries available.

When choosing a product, take into account the power, coupled with such characteristics as the consumption of the coloring material, the size of the nozzle. As a rule, the more powerful the spray gun, the higher its performance and the greater the weight.

If you want a good and powerful option for home use, it is worth buying a 300-600W device. Professional equipment has a high power (up to 1000 W and more).

Determining the type of pump, proceed from considerations of convenience. Remote-type options look like vacuum cleaners. These are floor types of models that facilitate the weight load on the craftsman. With this staining, only the pistol itself is held in their hands.

Products with a built-in pump require skill. They have a stable torch shape, but when working, you cannot avoid the coloring fog, which is bad when painting in closed rooms.

It is important to determine the volume of the tank. If it is sufficient, the need for constant refueling will disappear. So it will be possible to reduce the working time and cover a large area at a time. The optimal value is 1-2 liters.

Not all spray guns are equally good at spraying materials of varying viscosities. Indicators 20-30 din indicate that the models are designed for spraying primers, antiseptic mixtures, as well as liquid dyes. Viscosity values for thick materials are from 40 din.

When choosing a model of a paint sprayer, they pay attention to compatibility with specific substances. Not all devices can properly distribute thick facade and oil paint.

It is best to purchase a product with adjustment options.... For example, for versions with an internal pump, these may be options for adjusting the paint supply as well as the flare shape.

External blower units have options. This is usually the setting for the nozzle diameter, air flow and pressure. In addition, some varieties are equipped with fast cleaning.

Usage Tips

In order for the surface staining to be uniform and effective, it is necessary to use the purchased device correctly.

Before painting the prepared base, it is necessary to cover with a film everything that can become stained due to the settling of the dye. You shouldn't start work without protection. When it is necessary to partially paint an object, they take a film and masking tape, create the necessary contours with their help.

If work is planned indoors, you need to take care of the ventilation system. When she is not there, they open windows or doors. Also, do not forget about the means of protection.

In order for the coverage to be uniform and of high quality, you need to avoid common mistakes.

-

For good paint distribution, use a nozzle with a smaller orifice... Before work, it is necessary to check whether the openings of the device are not clogged.

-

In case of poor-quality spraying, the nozzles must be rinsed or cleaned. Sometimes the solution is to add fluid.

-

To prevent the formation of a coloring mist, it is worth reducing the pressure. In addition to this setting, it is necessary to replace the nozzle, change the diameter of its hole.

-

If the liquid does not spray, you need to disassemble the sprayer... It is likely that the filter is broken or the nozzle is clogged with large abrasive particles of the material used.

To prevent the spray gun from clogging, sometimes you have to dilute the paint.

Read the instructions for use before using the device. Compliance with all the rules contributes to high-quality work and prevention of breakdowns.

Look at the paint package before using the spray gun. It should say whether it is compatible with this model. Then the liquid is thoroughly stirred, after which part is poured into a separate container.

In order to prevent breakdowns, it is filtered, after which it is poured into the container of the spray gun. You need to fill the tank with the composition by 2/3, then you need to check the settings. To do this, take a newspaper and apply a layer of paint directly to it.

Before painting, pay attention to the viscosity. Too thick material will not fill the cracks and spoil the appearance of the finished coating. The solvent is selected based on the type of paint. For example, drying oil is used for oil, and distilled water for water-dispersed water.

If too much paint is supplied, tighten the adjusting screw. It is also worth adjusting the air flow to the side jets. In a small area, the air supply should be reduced.

After making the settings, put on special clothing, a respirator, goggles and gloves. Then they get to work.

When painting the surface, keep the distance from the spray hole to the base to be trimmed. The minimum distance should be 20 cm. At lower values, drips cannot be avoided.

Increasing the distance will require more paint. Painting should be carried out holding the tool perpendicular to the surface to be trimmed. Hand movements should be uniform.

Do not slow down or speed up the movement of the paint gun. The walls are painted in stripes from top to bottom. Each next strip should go slightly into the previous one. After the first layer, you need to apply another 1 layer of material. Re-staining is performed not earlier than the drying of the first layer.

When painting wood, hand movements should be along the grain. This will preserve the natural pattern of the tree.

The comment was sent successfully.