Choosing a compressor for a spray gun

It is impossible to produce high-quality painting without the right tools. After all, the needs of industrial and home dyeing are different. How different types and materials of painted structures are. That is why it is so important to choose the right not only paint, spray gun, but also a compressor for it.

Features of the device

The compressor is a special machine, the action of which is aimed at compressing air and supplying gaseous substances. Like many other mechanisms, the compressor for a spray gun has a number of features. The main one is the need for an electric motor. There are motors of different power. The more powerful the engine, the higher the efficiency of the compressor. Accordingly, the electricity consumption increases in direct proportion to the engine power.

A separate feature can be called the variety of designs of power machines. There are many differences in their design. They are aimed at making the painting work as comfortable and high-quality as possible. The features also include the material for the manufacture of compressors.

They are mainly produced using stainless steel, which is highly resistant to weathering and chemical influences.

Views

Compressors differ from each other in terms of application, principle of operation, type of drive motor and power. The most common type is considered to be air, used mainly for painting cars. Air power machines, in turn, are divided into pneumatic and screw.

The second type has the highest power among compressors. This is a system with external screws, the rotation of which significantly speeds up the work process compared to a piston system. Also, among the many compressor units, inverter and inverter-linear types can be distinguished.

A feature of these devices is the absence of an electric motor.

The inverter mechanism works due to magnetic fields, while the inverter-linear mechanism operates due to the built-in piston of the pump. This contributes to a smooth change in the frequency of the air supply. Compressor units are designed for both industrial scale production and home use.

Industrial compressors have a 380 V motor, while household compressors are equipped with a 220 V electric motor. Each compressor is designed for a specific application. Like other devices, power machines have their own advantages and disadvantages. To better understand the principles of operation of compressor units, it is worth considering the most common types.

Screw

Screw compressors have the highest performance compared to other types. These installations are relatively small in size. The device is represented by screw rotors, divided into a master and a slave. The main rotor is connected to the motor by means of gears. Screw compressors are equipped with bearing chambers. Air is compressed by rotating the screws.

There are screw installations operating with oil and without it. Oil compressor machines have a lower rotational speed of the screws, and, therefore, less power.

The advantages of screw compressors include the following.

- Installations of this type are capable of operating continuously for 15-20 hours.

- Electronic systems allow the compressor to be adjusted to the smallest parameters.

- Screw compressors have the highest efficiency while saving electricity.

- The devices supply a large amount of air at high pressure.

- Screw installations do not require periodic maintenance.

With all the pluses, of course, there are also minuses.

- High price.

- Complicated setup.

- Impossibility of repair in case of breakage or wear of the rotors.

Basically, such installations are used at service stations, as well as in places where continuous operation of devices is required.

Reciprocating

The piston compressor compresses the air due to the movement of the piston in the cylinder... Such installations are both oil and "dry compression". The piston unit "dry compression" is characterized by a complete absence of oil in the system. The wear resistance of the parts is ensured by low friction and durable materials of manufacture. The pluses of such an installation include the following.

- Small size, light weight.

- The pressure is 7-10 atmospheres.

- High performance.

- Relatively low price.

This type has enough disadvantages.

- Fast heating. Therefore, there is no possibility of continuous use.

- Reduced wear resistance.

- Increased noise production.

The oil-lubricated piston compressor is highly wear-resistant. All structural parts are coated with a lubricant, which reduces friction damage. The oil is stored in the crankcase of the piston system. From there, it is sprayed and fed to the gears, after which it hits all the parts. This mechanism has several advantages.

- Increased efficiency due to reduced friction.

- Reduced heat generation.

- The installation is capable of operating for a longer time.

The disadvantages include the need for periodic maintenance of the equipment. It is necessary to change the oil.

This type of compressor is mainly found either in small businesses or in home workshops.

Coaxial and belt driven

A distinctive feature of coaxial compressors is that the piston unit is directly connected to the engine. This significantly increases the number of engine revolutions and piston strokes. However, this design overheats quickly. Due to the frequent movements, the rings of the piston group wear out very quickly and require periodic replacement.

Belt-driven units are distinguished by the fact that the piston group is not directly connected to the engine. The movement is carried out through friction wheels and, in fact, the belt drive itself. With this design, the belt driven compressor has these advantages.

- Due to the reduced number of engine and piston revolutions, the wear resistance of the compressor parts is increased.

- The belt drive reduces the load on the engine.

- This unit has a higher capacity than a coaxial driven compressor.

- Despite the high power, the compressor saves electricity.

The only drawback of this type of compressor is high noise level.

This is explained by the fact that the engine runs at high speeds.

Popular models

Compressor units have different characteristics and prices. There are the most popular models that have proven to be excellent performance.

"Kraton" АС-140-8-OFS

This relatively inexpensive coaxial drive compressor is useful not only for painting but also for inflating tires.... The design is equipped with an air filter that removes the recycled oil. A built-in fuse protects the unit from overloads. The electric motor is equipped with a special protection to prevent overheating. Rubber feet on the feet reduce vibration. The unit weighs only 15 kg. The compressor runs quietly. It is compact and easy to transport as it is equipped with a special carry handle. The cost varies from 6,000 to 8,000 rubles.

Metabo Basic 250-24 W

The oil-type piston compressor has a capacity of up to 200 l / min. The engine is protected by a special casing that prevents oil from entering it. This model has a high build quality and a spacious receiver. A condensate drain valve is also built into the structure. Among the shortcomings can be noted a short handle for transportation. The price of the compressor is 10,000 - 13,000 rubles.

Fubag VCF / 100 CM3

The compressor of the German manufacturer, equipped with a belt drive, has a receiver of 100 liters. Pressure gauges mounted on the body of the device allow the pressure to be monitored. Wheels and a handle make it easy to move the compressor machine. The motor is protected from overheating and has an automatic start mechanism. The good thing about the compressor is that it has a cast iron sleeve. It also has high performance and has removable rapid connections. The manufacturer gives a 2-year warranty for its products. The installation cost starts from 30,000 rubles.

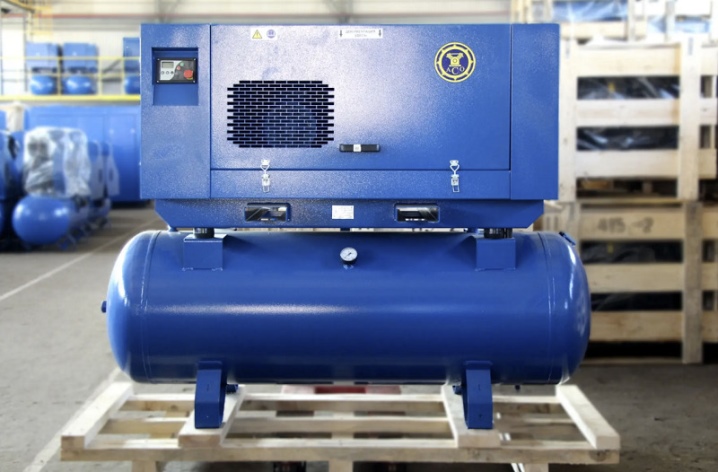

COMARO XB 11-08

This is a screw compressor designed for small businesses and service stations. The body consists of sound and vibration isolation plates. As a result, the device requires less maintenance. The housing is equipped with an emergency stop button. Sound absorption, high power and performance are not all the advantages of this model. The compressor is easy to operate and has a pressure of 8 bar. The cost of an electric car is 225,000 - 330,000 rubles.

Hyundai HYC 1824S

This oil-free model has a pressure of 8 bar. The device is suitable for spray guns, sandblasting machines for cleaning from corrosion, for inflating tires. This compressor has a low noise level. The design has a spacious 24 liter receiver. The compressor keeps pressure stably, but needs breaks. The price starts from 10,000 rubles.

How to choose?

In order to choose the right compressor, you need to decide for the purpose of using it. After all, the needs of large-scale production are significantly different from the needs of household ones. Painting materials are also important. For example, oil paints require a piston compressor. It will create enough pressure for the layer to fit better on the surface of the parts.

Taking into account the pressure of the compressor units will help to make the choice. For garages, compressors with a pressure of 8-16 bar are suitable. It all depends on the amount of products to be painted. If you plan to paint at home, do not choose high power compressors.

Low-power portable devices are perfect for home.

There are small compressors that have good performance. When it comes to professional painting, compressors with a receiver volume of less than 50 liters will be too weak. It is better to use electric vehicles that have a receiver volume of 50 liters or more.

Choosing a compressor you need to carefully study its characteristics. Experts recommend choosing compressors with a margin for performance and pressure... After all, the terms of use can affect these characteristics. Loss of pressure or performance sometimes occurs. It is important that the compressor has a capacity reserve of about 25-30%, a pressure reserve of 2 bar.

How to use?

Before starting work, you need to set up the compressor and atomizer. First you need to plug the device into a power outlet. After that, you need to wait until the cylinder is completely filled with air. The paint gun is connected with a hose for the compressor unit. Then a test press is made. If everything is set up correctly, air will come out of the atomizer.

It is very important that the paint you are going to work with has a uniform consistency. If lumps are present, you can strain it through cheesecloth.It is not recommended to start painting with non-uniform paint. The lumps will quickly clog the spray nozzle and you will have to stop work. When the paint has been tested for uniformity, it is poured into the spray bottle.

Do not pour paint to the top. This can dry out the top coat of paint, making it difficult to open the spray bottle. Next, the spray paint flow is adjusted. To do this, use an unnecessary surface or part. The flow is controlled by rotating the spray head. When the preparation is done, you can start painting.

It is best to carry out staining in a special protective suit. It is imperative to wear a respirator and goggles. At the end of the work, the compressor is disconnected from the socket. If the work is carried out in a cold room or outdoors, it is imperative to drain the condensate that forms inside the cylinder. This can be done using a special tap located on the compressor housing.

A competent approach to the selection of a compressor will significantly improve the quality of the work performed.

It is necessary to carefully study the parameters of the compressor units in order to choose what you need.

The comment was sent successfully.