Boiler room reserve fuel: description and application rules

Reserve fuel is a kind of strategic reserve of the boiler house in case of any interruptions in the supply of the main fuel. According to the approved standards, the transition to reserve fuel should be as invisible to the consumer as possible. The stock, in fact, must be created for this. It is necessary that such a reserve ensures the operation of the heating equipment in the "survival" mode until the main power source is restored. It should be borne in mind that some social facilities, primarily children's and medical institutions, should receive heat energy in full.

Characteristic

The reserve fuel of the boiler house is the so-called irreducible and operational fuel. In the first case, this is the margin that must ensure the functioning of heating equipment at the lowest temperatures without comfort in heated rooms. And here operating fuel is the reserve that ensures the normal functioning of heated objects. It follows from this that in different situations, different regulations for the use of the reserve can be applied.

The absence of such a reserve is unacceptable in the conditions of a long winter, typical for most of the territory of Russia. Interruptions in the supply of solid (coal) and liquid (fuel oil, diesel fuel) fuels may occur due to weather conditions.

Unfortunately, there are still accidents on pipelines transporting the same liquid hydrocarbons or natural gas.

Views

The classification of reserve and main fuel by type looks the same.

Solid fuels can be coal, peat or shale briquettes, and finally, wood. The efficiency of solid energy carriers is different. Coals can have the greatest heat transfer, their variety is very large, briquettes in their thermal characteristics do not differ much from firewood. A feature may be that all fossil solid fuels, as a rule, contain one or another amount of mineral components that affect the design of furnaces, chimneys and heated equipment. The composition of the combustion products of these fuels is the most diverse and can vary depending on their origin. Boiler houses, the main fuel of which is coal, is very difficult to convert to liquid or gaseous fuel, since this requires serious technological changes, therefore, most often, the same coal is used as a reserve.

But there are also advantages - firewood can be used for heating, which is quite affordable in most regions of Russia.

The liquid fuel for boiler houses can be diesel oil or fuel oil. One of the features of this fuel category is its highest efficiency. However, providing a reserve stock of liquid fuel requires serious material and technical costs. In winter, the container in which the reserve is stored will have to be additionally heated, since with a significant decrease in temperature, the physical properties of such a fuel change, and it loses its inherent fluidity, that is, unheated liquid fuel cannot be used in the boiler room until it the temperature will not rise with the ambient temperature during the warmer months. Thus, storing a reserve of a liquid energy carrier requires constant additional energy consumption for heating, which significantly reduces its efficiency.

Gaseous hydrocarbons are specially prepared mixtures of natural combustible gases. Currently, this type of fuel is the most popular - both as the main and as a backup. This is due to a number of gas advantages. Firstly, it does not lose its properties even at very low temperatures, and storage tanks do not need to be heated. Secondly, the cost of gas fuel is several times lower compared to liquid fuel. In addition, it is quite easy to transport it through gas pipelines. During its operation, harmful combustion products are practically not emitted, which, in addition to the absence of a negative impact on the environment, significantly extends the service life of the gas boiler equipment. Also, unlike diesel fuel, which can be in demand, for example, for refueling vehicles, which often gives rise to the vicious practice of stealing from the reserve stock, gaseous fuel cannot be drained. Well, the transfer of a gas boiler house to reserve fuel, unlike coal or fuel oil, may go unnoticed for the user, since it will not require any re-equipment and, accordingly, stopping the heat supply.

Appointment

As already mentioned, the purpose of the reserve for the boiler room is to ensure uninterrupted heat supply to the heated objects. In the harsh conditions of a prolonged cold period, when negative temperatures last for at least six months, the need for such a reserve is beyond doubt. Any stoppage of the boiler house operation is fraught with disastrous consequences. It is unnecessary to talk about the need to maintain a satisfactory microclimate in heated rooms - this is not even discussed in a long winter. In the cold season, it is also important to prevent the failure of heating equipment, which can occur when the heat supply is interrupted. Such a scenario will require serious capital investments to restore the functioning of the heating system.

According to the regulations, the reserve fuel reserve is strictly regulated by federal legislation. (Order of the Ministry of Energy of the Russian Federation of August 10, 2012 No. 337). The lack of such a stock is unacceptable and may have legal consequences.

The volume and nature of the reserve for boiler houses on solid or liquid fuels, for a gas boiler house and a mixed type boiler house have been determined.

Application features

The volume of the stock is calculated according to the norms, which depend on a number of factors:

- data on the stock of the main and reserve fuel as of October 1 of the last reporting year;

- modes of transportation (modes of transport, nature and condition of transport routes);

- information on the capacity of tanks or coal storages;

- data on the average daily consumption in the cold season for previous years;

- the condition of the boiler room equipment;

- the presence of objects, the heating of which cannot be stopped;

- the maximum permissible load on the boiler room during the operation of all heat consumers;

- load on heating equipment in the "survival" mode.

The calculation of the amount of reserve stock is carried out in accordance with the approved standards established in accordance with the Procedure for determining the standards for fuel reserves adopted in 2012 by the Ministry of Justice of the Russian Federation.

Basic data for calculation:

- average daily planned consumption in the coldest month;

- the number of days when a particular type of fuel is used.

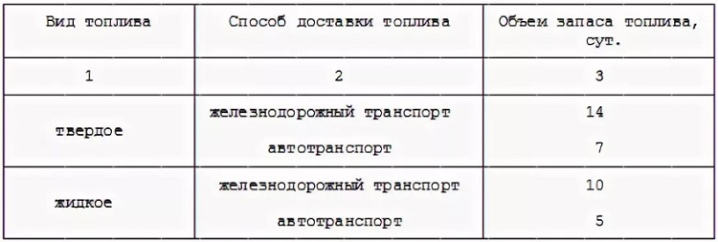

The number of days depends on the method of transportation. So, when delivering coal by rail, the frequency of delivery is assumed to be once every two weeks (14 days), but if the fuel is delivered by road, the frequency of delivery is reduced to one week (7 days).

In the case of liquid fuel, the delivery times are reduced to 10 and 5 days, respectively.

You can find out who a boiler room operator is below.

The comment was sent successfully.