Overview and operation of hot water boiler houses

In the context of a periodic rise in the cost of payment for utilities, many individuals and legal entities are switching to an independent supply of hot water and a heating system, abandoning the regional one. To do this, they set their own hot water boilers.

Peculiarities

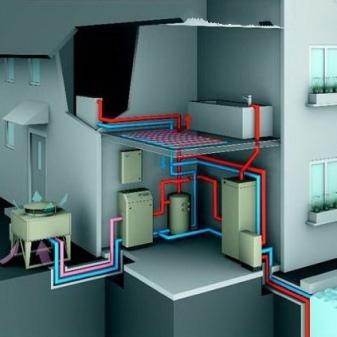

A hot water boiler house is an independent system that supplies hot water and heating... It works great in all weather conditions, has minimal heat loss and high efficiency. Its main task is to heat the coolant, which further provides the consumer with thermal energy. Thanks to such a system, the user has constant access to hot water, as well as warmth in the room.

Such boiler rooms installed according to special design not far from the consumer, this reduces the cost of maintaining the coolant. Special installations and workflow automation contribute to the achievement of an efficiency of about 93%. The boiler room is easy to install, since the blocks and modules are assembled into one structure, consisting of devices and assemblies.

It is possible to set up the operation of an automatic boiler house in a certain mode, while the presence of personnel is not required.

During work, there is no production of harmful substances that are harmful to the environment... By reducing the cost of electronic carriers, heat losses are reduced. Users note that it is possible to recoup the cost of a boiler plant in 3 years. Regardless of the type of fuel consumed, boiler houses have their own scheme of work... Its peculiarity is that the coolant heats up about 115 degrees, then gives off heat to the heating system. Further, the liquid passes into a vapor state at a temperature of 100 degrees.

At the same time, it does not boil, because there is always an increased pressure in the boiler. The higher it is, the more the risk of boiling is eliminated, and hence the appearance of scale. A certain type of fuel burns in the firebox, through its surface heat is transferred to the water moving through the heating system.

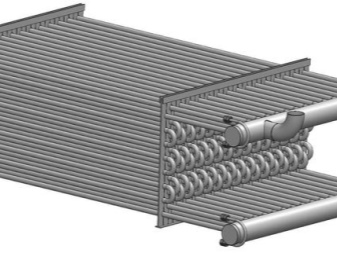

Each type of boiler design is designed so that fuel combustion occurs with the most efficient heat transfer.

What elements does it consist of?

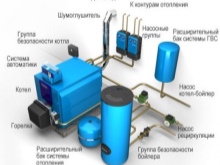

Any heating boiler room is connected to the consumer using heating mains... However, its main element is boiler or combustion device... For full-fledged work, you also need additional devices, such as a mechanism for feeding and burning fuel, various heat exchange units, heaters, special devices for chemical preparation and water purification, also network and circulation pumps for liquids, fans, gas path and chimney, air exchange system and automatic regulation of safe fuel combustion, heat exchangers and control panel.

In order for the work to be the most economical, special additional devices are built into the boiler rooms: a water economizer and an air heater, thanks to which not only water is heated, but also air.

There is a device for ash removal and fuel supply, a utilizer of flue gases and feed water... Also provided heat and light control devices with automation, who monitor the smooth operation of each unit of the boiler room.

In order to control the compensation of the thermal expansion of the heat carrier from the heat supply system, special membrane and expansion tanks. In powerful boiler rooms these tanks equipped with an automatic make-up system... To ensure optimal boiler operation, several fortified chimneys... They are made of stainless steel or carbon steel. Their height is determined based on the calculation of the zone of dispersion of harmful emissions. Also in the boiler rooms there is security and fire system and gas sensors.

What are they?

All hot water boilers differ in the type of fuel used... They are gas, solid fuel and liquid fuel. For a certain type, the boiler will have its own design features. He will have a special burner, which can be atmospheric or replaceable-inflatable. Atmospheric designed for a specific fuel, and thanks to replaceable-inflatable you can change one type of fuel for another.

Solid fuel mini-boiler rooms fired with wood, coal, shavings and peat. An integral part of this type of installation is structural unit... This is a tank for heating water. The solid fuel boiler has a very spacious firebox or combustion chamber with a grate, under which there is a container for collecting ash, and at the top there is a chimney.

The principle of operation of such boiler houses consists in burning fuel, which transfers its heat to a cast-iron heat exchanger. And he transfers heat to the air inside.

Then the air passes along the inner planes and goes to the radiator, which is inside the cold water tank. While moving through the heat exchanger, the air transfers its heat to the water, while it heats it up. Such boiler rooms must work in the presence of special personnel, which monitors the fuel loading and the temperature inside the tank. Solid fuel plants are considered less economical, since there is a lot of fuel consumption. Their advantage is their low weight, and there are no special requirements for operation.

Gas-fired boiler houses are easy to operate and have high power. They are equipped with single-circuit and double-circuit boilers, designed to provide hot water and space heating at the same time. They can be built-in and free-standing, roof-top or platform-mounted. For transportation, they are non-transportable or block-modular.

The principle of operation of gas boiler rooms consists in the fact that the gas automatically moves along the highway into the combustion chamber, in which all functions are controlled by different systems and sensors. In such a chain, automation controls almost everything, from the strength of the flame to the disposal of combustion products. The heat generated during combustion heats up the heat exchanger, and the heated water moves to the distribution circuit and then to the consumer.

Liquid fuel boilers operate according to the basic principle. They are easy to use, quickly put into operation. They run on a diesel engine that provides a large amount of efficiency, up to 90%. In addition, you can always change the type of fuel to gas, for this you just need to change the burner. Such boiler houses have an affordable price and low energy consumption; they require minimal paperwork to operate. The only one disadvantage is a requirement for the quality of fuel, since if it is not observed, the equipment may fail.

A powerful ventilation system is also needed that removes the unpleasant smell of diesel fuel.

Operating rules

After installing the boiler, its first start-up is performed, which is characterized by a rather complicated process. It is clearly associated with serious rules and serious instructions.

Before kindling the boiler room, if it is on diesel or solid fuel, it is necessary to inspect it for breakdowns and operational readiness.

- It is necessary to inspect the superheater, air heater, collector trim and water supply, as well as all components in the water heating system.

- All third-party items, debris from the furnace and flue gas ducts must be disposed of.

- You also need to inspect for plugs on the gas line, steam, water or drain lines.

- After revising the additional equipment, it must be run in idle operation, during this there should be no vibration or knocking sounds. If any breakdowns occur during the inspection, they must be eliminated before starting the boiler.

- Before the first ignition, you need to open the shut-off and individual dampers, and close the fan guides together with the exhauster.

During work on automatic hot water boilers a specialist must be present, which controls fuel consumption, pressure condition and degrees in the boiler. For normal operation, chemical water treatment is mandatory, as well as control of the appropriate supply of water to the system. Water is supplied to the boiler manually or automatically. The control over the power supply is carried out by the operator according to the data of the devices, indicating the degree of water in the drum.

For accounting in the boiler room, a special magazine, which controls water treatment, indicators of the results of water analysis, the execution of the timing of the blowdown of boilers and work on equipment repair. Boilers with a capacity less than 0.7 t / h must have regular cleaning, if the scale is 5 mm thick.

The operation of the water heating system is monitored by persons over 18 years of age who have passed a medical examination, have a special education and a corresponding confirmation.

Hot water boiler rooms must not be left unattended. until the complete end of combustion in the furnace, removal of fuel waste from it and pressure reduction to zero. Unauthorized people should not be allowed to the equipment of boiler rooms, unless they have received permission from the administration. The room, boilers and all auxiliary equipment must always be in working order and as clean as possible. Do not keep outside and obstructing objects in the building. Doorways should be clear and doors should be easy to open.

Before starting the system, the ducts must be ventilated, illuminated, protected from the possible ingress of gas dust. The state of the furnace and gas ducts is confirmed by the analysis result. If there are signs of gas contamination, fire must not be used in the boiler room. Tightening of bolts and clamps during boiler operation should be carried out with the utmost care, only with a special tool, without using extension levers, under the authority of a responsible person.

For information on how to make a boiler room so that the gas service will accept it, see the next video.

The comment was sent successfully.