How much does the cinder block weigh?

Since ancient times, building materials have been trying to reduce the cost and simplify their use. But in addition to financial and geometric indicators, strength and thermal conductivity, you also need to know the total mass. Only by it can one judge the applicability of certain products in a particular case, about the optimal options for performing tasks.

Why do you need to know the weight?

The obvious answer - "for the correct calculation of the foundation" - does not exhaust the entire depth of the problem. It is important to remember that the severity of a structure is inversely proportional to its strength. And even with the complete identity of materials, with a high quality workmanship, the difference still remains extremely significant for achieving the result. So, when using the classic type of cinder blocks (indeed, consisting of metallurgical slag), the severity is determined by the size of its particles. When using mainly coarse slag, the structure becomes lighter, becomes less strong, but more economical in terms of heat consumption.

Small slag is manifested, accordingly, not only by making the product heavier. It contributes to its increased strength. But at the same time, the thermal characteristics deteriorate. The addition of quartz sand instead of part of the fine slag particles, which is practiced in some cases, increases the strength of the structure, because the maximum loads are concentrated on the coarse filler. Of course, this technique inevitably affects the severity of the design used.

Composition and properties

Among the artificially obtained building stones, cinder blocks are distinguished by the fact that they were once made only with slag filling, hence the name. But today this design has become much more diverse in its parameters.

So, in the production of cinder blocks, fillers such as:

- gravel;

- crushed granite;

- broken glass;

- crushed brick;

- concrete;

- expanded clay;

- volcanic ash and a number of other substances.

The advantages of using blocks are:

- long period of operation;

- flame resistance;

- relatively weak thermal conductivity;

- fast construction;

- the possibility of obtaining parts in artisanal conditions;

- a wide range of geometric solutions.

But we must not forget that cinder blocks almost do not extinguish noise and are easily soaked in water. The thermal conductivity of solid structures is not always satisfactory. Such elements are poorly suited for pulling pipelines and cable lines.

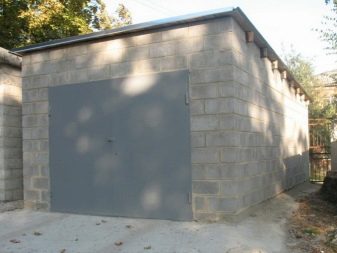

Therefore, for the most part they are used:

- for garages;

- for summer kitchens;

- for other ancillary structures;

- as a finishing and decorative material.

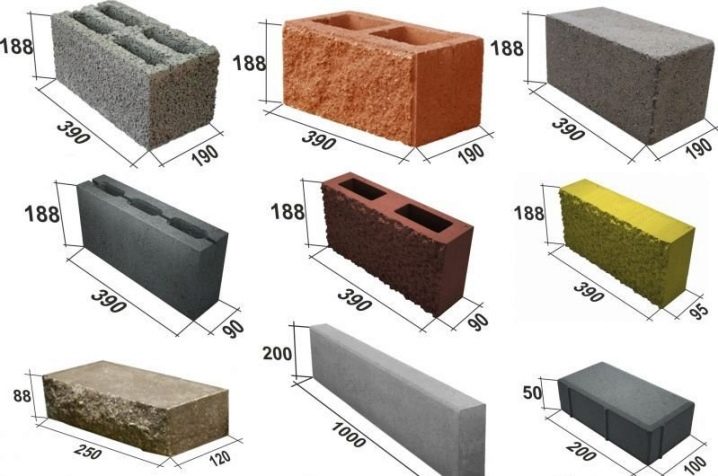

Mass gradation

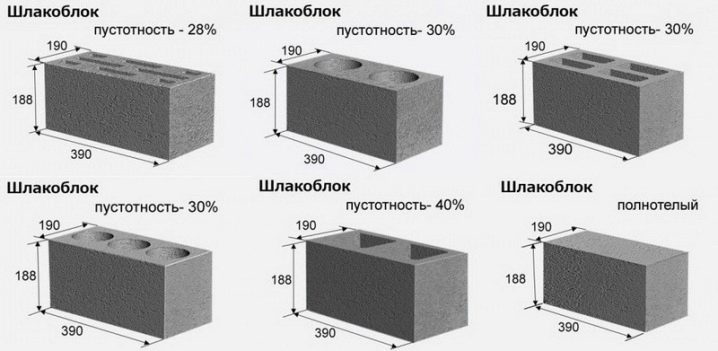

The manufacture of cinder blocks for the construction of specific facilities is widespread; they are often made by hand. Therefore, the size of 1 piece can be very different depending on the need arisen. An unofficial standard, that is, cinder blocks considered universal, are 39 cm in length, 18.8 cm in height and 19 cm in width. But the mass is influenced not only by the space occupied, there is an important difference between full-bodied and empty blocks inside.

Voids are purposefully created because they allow you to:

- reduce the weight of the finished structure;

- reduce heat loss;

- save materials;

- while maintaining the strength of structures at a decent level.

Some blocks have a pair of square cavities, which means that air accounts for 40% of the block volume. This indicator is least of all (28%) when a number of slots are placed inside.If you create four slots in the form of a rectangle or 2 or 3 circular slots, the voids account for 30%. A block of conventionally standard size, manufactured in an industrial environment, weighs from 12 to 28 kg. Accordingly, the specific gravity reaches 49-100 kg per 1 sq. m.

You can more accurately determine the characteristics if you take into account the material used and the field of application. So, solid cinder blocks are designed to form foundations, they can also be used in load-bearing walls and in basements. Hollow structures are used to construct walls inside houses and partitions. There are facing products that duplicate the appearance of various materials and are intended for decoration. Partition cinder blocks are very light (both in general and in terms of one cube), are inexpensive and create a minimum load on the base.

Torn blocks have the same surface appearance as broken bricks. Such products are mostly needed for decorative purposes. Decorating columns, fences and pediments are formed from colored parts, which are added with chalk or crushed brick. As for the size, the above dimension of 39x19x18.8 cm is typical only for ordinary structures. For three-quarter cinder blocks, the norm is a proportion of 29x19x18.8 cm.

The half-type block has two sides of 19 cm each, and the partition walls differ in lengths of 59 or 39 cm, and a width of 9 cm. The structures intended for the chimney have two sides of 39 cm each. A large-sized cinder block 400x200x200 mm has the greatest weight - 26 kg when using expanded clay concrete. If the block 20x20x40 cm is made of sand cement, its weight increases to 29 kg. It is unacceptable to use cinder blocks, which differ in length and width from typical dimensions by more than 3 mm.

For deviation in height, a less rigid barrier is provided - 4 mm. But it is also impossible to use blocks of any size in construction that have concrete shells deeper than 0.4 cm, as well as outgrowths and grooves over 0.2 cm.The maximum permissible level of chips on the outer and inner edges is no more than 0.5 cm with a length of 0 , 5 m. It is important to take into account all these circumstances - along with the mass - when selecting cinder blocks and obtaining them independently.

The situation is categorically unacceptable when, in an effort to keep the conformity of dimensions and severity at any cost, the quality is lowered.

The cost of finished blocks is determined not only by their mass (more precisely, the number of voids and the format of these voids). Specific technological parameters are taken into account, as well as the popularity of the manufacturer, and the distance of transportation. Knowing the exact composition and its effect on the severity of structures allows you to order the most suitable products and monitor their compliance with the requirements.

Important: when used in the production of blast-furnace slag, it is not recommended to use blocks in the construction of residential premises and places for keeping animals.

The only area of their use is secondary outbuildings. It is required to take into account that even the heaviest and most durable products are fragile. When unloading, storing and using, they should be protected from falls and strong impacts. Seams should be made as thin as possible. Their excessive thickness opens up a convenient path for frost.

For the dimensions of the cinder block, see the next video.

The comment was sent successfully.