Dimensions and features of red brick

When determining the size of a red brick, the thickness of a standard single ordinary product is of great importance when performing construction work of any complexity. Both wall masonry and many other activities require the use of this practical and safe material. The height, length and other dimensions of an ordinary one-and-a-half brick largely depend on which variety the selected type of material belongs to. It is this factor that largely affects all the characteristics of building ceramic blocks.

Peculiarities

Solid red brick is a completely unique building material that combines the possibilities of natural and artificial components. It is produced under the influence of high temperatures, formed from specialized grades of clay and allows you to provide an optimal balance of strength, environmental friendliness and durability. The absence of voids in the finished ceramic product provides it with a homogeneous composition and allows it to maintain its original strength characteristics even with minor mechanical damage. This is of great importance when it comes to the construction of massive walls that are subject to the most intense loads.

When used in the construction of the foundation, solid brick prevents cracking and destruction of the structure under the influence of groundwater, frost, soil swelling. At the same time, the very process of laying is much more convenient and effective. For example, a solid ceramic block can be straightened in a row with a mallet. But there are also minor downsides. In comparison with hollow counterparts, red solid brick conducts and gives off heat better, has its own characteristics in terms of sound insulation. The weight of each product also matters. In this case, it fluctuates between 3.3-3.6 kg. The exact weight depends on the size and design.

Varieties

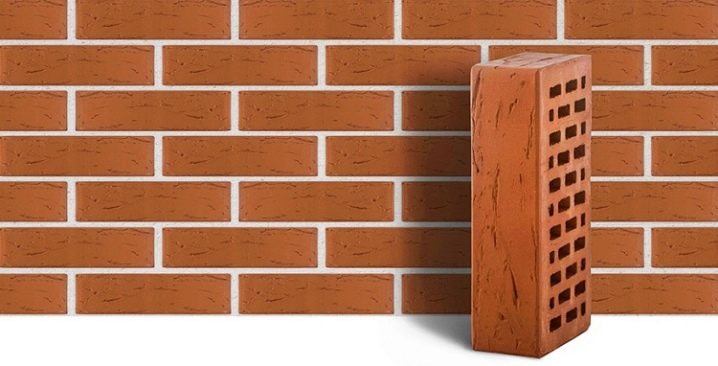

There are different types of ordinary red bricks. In total, you can find more than 15,000 options for such ceramic products on sale. Classic varieties of ordinary brick in a solid version are usually marked with M-150. For the arrangement of the basement floor of the foundation structure, the M-125 marking is used. To create fireplaces and other air heating devices, special kiln-type ceramics are used.

They can withstand contact with open fire, unlike ordinary solid or hollow products, they have heat resistance and a significant margin of safety. There is also a double or zabutovochny option - "loaf", used in the construction of load-bearing structures of buildings and structures. To form a rough layer of masonry, a special brick is used. It implies the subsequent finishing of the wall with facing materials.

Dimensions (edit)

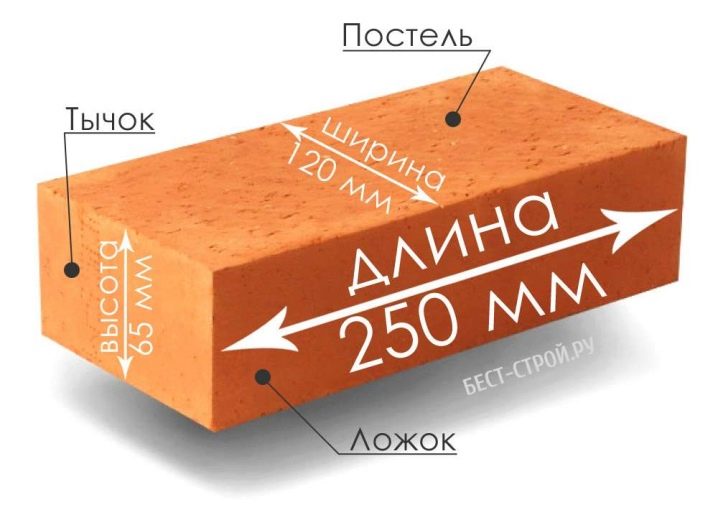

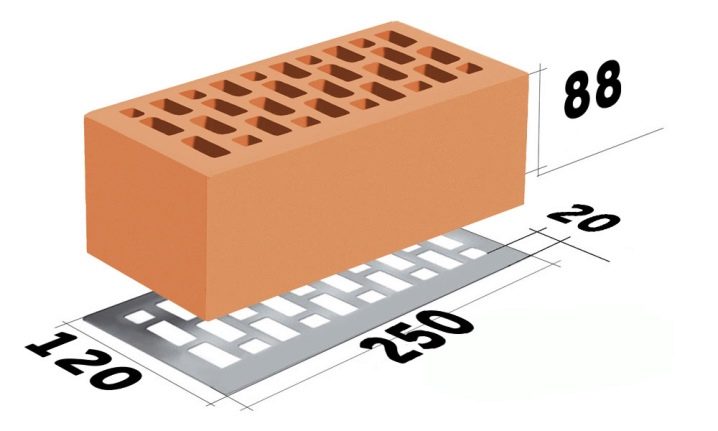

The normal size of red brick is established by the current requirements of the GOST 530-2007 standard. NF - this is what the marking of a typical product looks like. This standard product is characterized by a size of 250x120x65 mm. It is recommended to use this option for transverse-longitudinal masonry of walls. But not only it is used in the arrangement of walls or foundations. For example, eurobricks have the same thickness - 65 mm, but the dimensions are 250x85 mm.

For old-style products, dimensional characteristics are calculated individually. There is a GOST 8426-75 standard for the oven product. It is used to make thickened products, in which the width is 88, the length is 250, and the height is 120 mm. For a single red brick, there are standards that provide it with the necessary ease of installation. Since there are also one-and-a-half and double products, you should definitely take this point into account when selecting and purchasing the selected material. For example, double ceramic blocks are up to 138 mm thick. For one-and-a-half products, this figure is 88 mm.

In addition to the standard brick, there is also a non-standard one. The same version of the euro implies the use of a stone that has not 120, but 60 mm on the wide side. There is also the practice of directly making ceramic products to order. So, non-standard options are used as a basis for laying the roof, decorating the facade, decorating interior or exterior solutions. There are also craftsmen who create products by hand - in this case, it is impossible to talk about product standardization.

Permitted standard deviations

In the production of red solid bricks, certain standards and regulations are applied to distinguish products that comply with the standard from obvious and obvious defects. For example, the degree of mechanical damage available is important. The higher it is, the more likely the cull will be. But everything needs to be considered individually.

Why it is impossible to use defective products - no need to explain. They are really dangerous for the entire structure and can lead to the destruction of a building or structure over time. Violation of the recommendations set out in SNiP or GOST leads to the impossibility of making accurate calculations. Product parameters are arbitrary. And it turns out to be quite difficult to comply with the dimension. Among the permissible deviations from the norm are the following.

- The presence of small chips of ceramic material on the surface of the ribs. Slight blunting of the corner on one or two edges can also be performed. The length of the defect should not exceed 1.5 cm. If these parameters are exceeded, the use of bricks is not allowed.

- The unevenness of the edges, expressed in the curvature of the deviation from the given geometry, is allowed only if this indicator does not exceed 3 mm. In all other cases, the masonry indicators will be violated.

- Cracks on the surface of a ceramic stone. Among the acceptable options is only a single detection of cracking and only on longitudinally located edges. The ultimate crack depth is 30 mm. Deeper damage automatically translates the brick into a defective product.

Application area

Among the areas of application of solid red brick, the following options can be distinguished.

- For the base. Here this material is really irreplaceable, even a specialized version of this type of product is produced, capable of providing the necessary resistance to external influences. The absence of voids prevents its deformation, gives the finished base of a house or garage high strength, practicality and reliability. Brickwork, when properly formed, allows achieving high strength and durability, prevents erosion of the structure, the appearance of mold and mildew on its walls.

- For the oven. Ceramic blocks give off heat well when heated and can store it for a long time. Fire resistance is a really important factor for this material. That is why clay, initially undergoing heat treatment, becomes the best solution for making stone for building a hearth in which an open flame is to burn.

- For the foundation. Here, the requirements are almost the same as for the basement variety. For example, the main emphasis is on the strength characteristics of the product, its ability to withstand the effects of moisture and frost.

- For the elevator shaft. It requires certain strength characteristics, adherence to the humidity and ventilation regime. It is ceramic blocks that are an excellent solution for the successful operation of elevator structures for a long time.

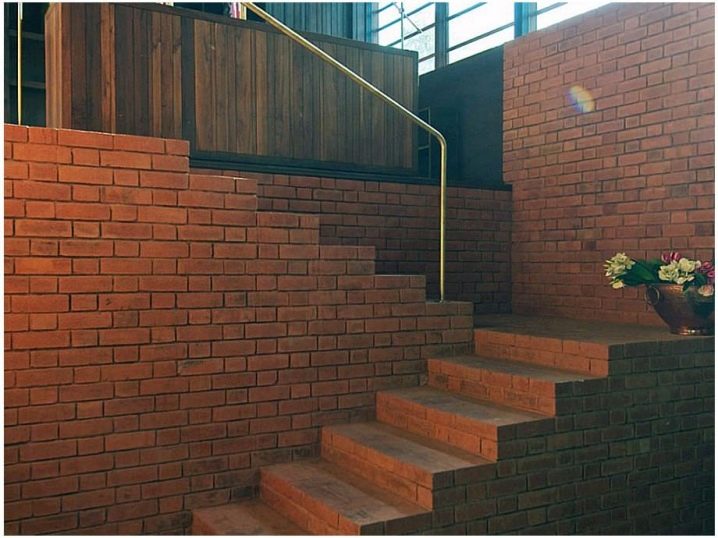

- For the construction of staircase structures. Here, the strength, sound insulation properties and versatility of bricks are also absolutely irreplaceable. Staircase structures of complex shape, with unusual geometric characteristics can be erected with it in a fairly short time and without additional effort.

- For basements. Here, brick is mainly used as an element of internal cladding, it is used as a structural element, it makes it possible to guarantee the achievement of an excellent result in use both when laying in half a brick and when creating thicker walls.

- For the formation of ventilated facades. The design of the outer wall of a building or structure requires maintaining a certain level of air exchange. It is the brick that helps to achieve the desired result and maintain the desired level of strength without losing the specified operational properties.

- To create partitions inside buildings and structures. It is the red brick in this case that makes it possible to obtain the best conditions for fast and high-quality construction of both solid and partial walls. It is worth paying attention to the fact that fences of balcony structures, columns and supporting elements in the interior are often made of this material.

Knowing the size and characteristics of red ceramic bricks allows you to find the most accurate practical application for it. Useful information about all the features of a building material is the key to successfully achieving the specified strength characteristics for buildings and structures. No matter how complex the project may be, in order to obtain accurate calculations, both an engineer and an ordinary foreman always need only the necessary minimum of information. In addition, the scope of application of solid red brick is so wide that it is not limited to the banal construction of walls or fences. Accordingly, the value of this material lies precisely in its convenient size and unique characteristics.

You can learn more about red brick in the video below.

The comment was sent successfully.