How to grout masonry joints?

Anyone wants his home to be the most beautiful, well-groomed and attractive to look at. Most often, a material such as brick is used for housing construction. In this case, the question arises of how to close up all the small gaps between the brick blocks? This requires grouting and all uneven surfaces. The grouting material highlights the contours of the facing brick.

Grouting brickwork

Grouting is the application of a special additional layer to the surface between the bricks after they have been laid. Such material is used for vertical or horizontal laying of the wall, after the excess mixture has been removed at the joints of each brick, but small irregularities remain. Grout, or as it is also called - joining, is used for just such purposes. The brickwork is beautiful and even. The layer that will protect against moisture has increased tightness and strength. As a result, the service life of the building increases.

They try to do the joining immediately after the building has been completed. Of course, there are also cases when this work is performed several years later. In this case, the wall has already absorbed a large amount of moisture and is gradually collapsing.

Grouting is done only on those walls on which subsequently no plastering or cladding work will be carried out.

Benefits of grouting

The embroidery is both decorative and practical.

The decorative properties include:

- emphasizing the texture of lines;

- highlighting a brick pattern;

- unification of all lines that have been laid out both horizontally and vertically;

- giving the facade austerity and clarity.

The practical characteristics are as follows:

- sound insulation increases with joining;

- it protects against excess moisture;

- keeps warm in the building;

- service life increases;

- tightness appears;

- small cracks are closed.

The grout overlaps the previous layer of cement, but in this way it is impossible to completely remove errors in the form of excess cement in the wall, its curvature and unevenness of the masonry.

When is the best time to join, and when to do it? Joining is possible only if the brick wall was erected exactly. After all, every seam has the same standard thickness. Horizontally this number is from 10 to 15 mm, and vertically from 7 to 14 mm.

There are several well-known and common methods of making do-it-yourself grout. Let's consider some examples in more detail.

Undercut

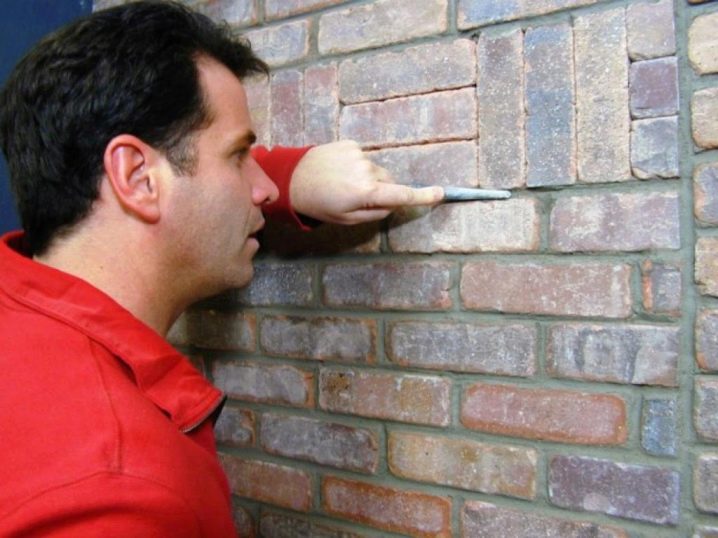

This is the easiest way to grout between bricks. For him, you will not even need to purchase a special tool - a narrow spatula.

First you need to dilute the grout, then apply it between the bricks. The mortar is usually made from cement. Excess material can be easily removed with a trowel (tool sanded on both sides with a curved wooden handle). It is necessary to let the layer harden a little, and then grind everything with a hard brush.

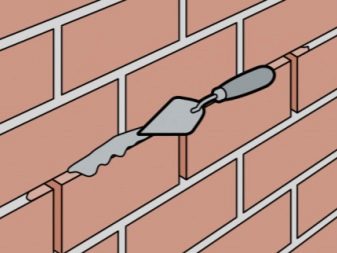

Fillet

This is the second method used by the masters. From the tools you will need: a small sharp spatula, which is called "jointing", the solution itself. The spatula should not be too thick and long, because it is with this tool that the mixture that will be applied to the surface will be tamped.The cement mortar must be laid on the surface of the masonry, remove the excess with a trowel, and then tamp the mixture between the bricks with a small sharp spatula.

Rectangular

This is the method that is better to entrust to the masters than to do it yourself, because it requires special skill and dexterity. A solution is taken out of the seams, about 4-5 mm, then the resulting gaps are again filled with a new mixture, more densely. This finish is beautiful to look at and attracts attention, but is not suitable for outdoor use, as it does not perform a water-repellent function.

There are two types of grout - cement-based and epoxy-based. They are quite different from each other. Cement grouts are more popular, easier to obtain, and cheaper in price.

Such grouts are produced by many companies (for example, Quick-mix is a popular supplier on the market). The material is removed from the surface quickly enough, and water, which is in every house, is used to dilute the mixture.

Epoxy grout is more expensive, not as readily available, and it is impossible to buy it in some cities. They are more effective than cement ones. In places where there is more moisture and there is an increased load, epoxy grout will be a cut and a half stronger than cement. They have a high durability indicator, as well as thermal insulation.

Self grout

To make your own grout mixture, you will need: cement, a mixture of gypsum and calcium carbonate (alabaster) and quartz sand. The ingredients must be mixed in proportions of 2 to 2 and 10.

Add water gradually to the mixture. The mass should not turn out to be too liquid or too viscous. To check if the resulting paste is ready for work, apply it to a trowel - it should not drain from it.

When it is necessary to obtain a white grout, lime or a commercial mixture can be added to the resulting mixture. If lime is used as a base for white, then when moisture gets on it, the white color will become more gray each time.

Gradual solidification of the mass occurs within three hours. After that, it loses its plasticity, it is more difficult to apply, it becomes impossible to work with it.

The following tools may be needed for grouting:

- spatula, trowel, drill, which will knead the mixture;

- cement, water and a bucket;

- a container in which the entire solution will be placed.

The first step is to prepare the surface for subsequent work - with a hard brush, go over all the seams, removing irregularities and excess. After that, you need to rinse the seams (if the wall is high and large, then it is best to use a hose), it is also worth washing the brick itself so that it is saturated with moisture.

In parallel, a solution is being prepared. First you need to choose the way how the grout will be carried out - concave or convex. It depends on what tools will be needed. A small amount of the mixture should be taken with a spatula, carefully tamped and rubbed over the seams. After that, you need to clean the seam with a brush in order to remove the excess. This concludes the work.

For grouting masonry joints, see the video below.

The comment was sent successfully.