Features of oven bricks and recommendations for its selection

It seems to many that the time of stoves and fireplaces has passed. However, even today some rural houses are heated with a stove, and fireplaces are an attribute of elite housing.

To prevent the furnace from cracking during operation, it should be laid out from a special refractory material. Heat-resistant brick differs from ordinary brick by its high resistance to high temperatures, it retains heat for a long time and gives it to the external environment for a long time.

Peculiarities

Kiln bricks are different:

- quartzto which sand is added;

- fireclay - it consists of refractory clay;

- the main - has a limestone-magnesian composition;

- carbonaceous - it is made from graphite and coke.

Each one is designed for a different purpose. For example, blast furnaces in metallurgical plants are laid out with carbonaceous material.

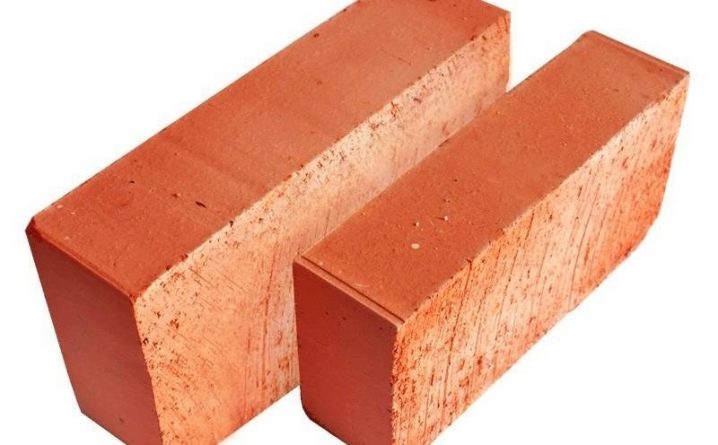

The most widespread in everyday life and industry was fireclay brick.... This is a solid stone, which contains 70% of refractory heat-resistant clay. Such material accumulates well and gives off heat for a long time. The air heated with the help of alumina bricks is considered curative by connoisseurs of a healthy lifestyle.

Fireclay bricks are in stable contact with an open fire, withstanding temperatures well above 1,000 degrees. The increased heat resistance allows it to heat up and cool down an infinite number of times, without collapsing and without changing its appearance. It is the fireclay brick that is involved in the creation of the firebox. (furnace area), and around the fireplace you can lay out a ceramic stone or any other that looks more attractive.

In addition to stoves and fireplaces, refractory bricks are used to create chimneys, furnaces for solid fuel boilers, for the construction of stationary barbecues and barbecues.

Specifications

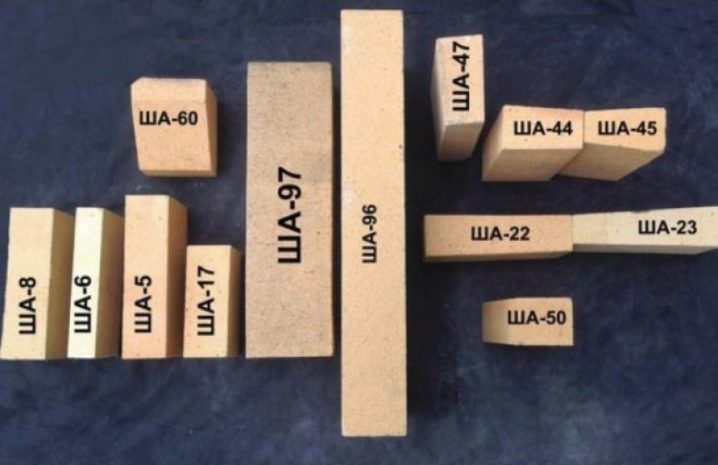

To find out the characteristics of the oven brick, you should carefully study its markings. The first letter indicates the type of product, for example, Ш - fireclay. The second letter indicates the degree of refractoriness, for example, A - 1400 degrees, B - 1350 degrees. Product dimensions are marked in the following numbers. The final letters indicate the manufacturer's abbreviation.

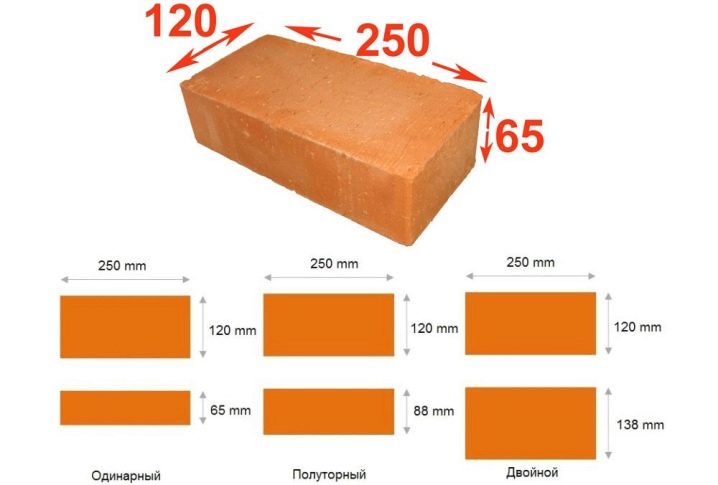

Size, weight

Kiln bricks are standard, double and one-and-a-half. The size of the standard (ШБ-5) is 23x11.4x6.5 cm, the larger one (ШБ-8) is 25x12.4x6.5 cm. Weight of 1 piece. bricks brand ШБ-5 - 3.5 kg. One ShB-8 brick weighs four kilograms.

The form

In addition to the traditional rectangular shape, manufacturers produce trapezoidal, wedge-shaped and arched oven bricks. The variety of species helps to use it in non-standard places.

Porosity and strength

The porosity of the stone affects the heat transfer. Such material is less durable, but it heats up easily and gives off heat to space for a long time. The denser the brick, the more heat-resistant and heavy it is, the more difficult it is to heat it up.

Density indicators correspond to the numbers 100, 150, 200, 250, 500. Having chosen a material with the highest values for our oven, we doom ourselves to a long and painful heating. The optimum density is 250, that is, 1800 kg / m3.

Frost resistance

Such marking makes it possible to understand how the material is able to absorb and release moisture.When choosing a brick for a chimney, you should pay attention only to frost-resistant products.

It can be concluded that the oven brick has the following characteristics:

- it is not too large and does not exert a tangible load on the foundation;

- optimal safety margin - 1800 kg / m;

- brickwork is able to accumulate heat and share it with the surrounding space for a long time;

- the building material has good adhesion to the mortar, which leads to savings in cement and does not create problems during installation;

- high refractoriness makes it possible to withstand temperatures up to one and a half thousand degrees;

- the brick is strong and durable: the perfect quality is not affected by numerous heating and cooling.

The negative aspects include the high cost of the product and the ability to absorb moisture.

Varieties

The construction market is rich in varieties of refractory bricks. They differ in strength, density, heat resistance and other characteristics. Each of them is designed for specific purposes. The most heat-resistant options are suitable for the firebox - they easily withstand direct contact with fire.

For chimneys, frost-resistant grades of stone are chosen, for facing - oven facing brick.

Chamotny

The most commonly used type of furnace material is solid fireclay bricks. It is popular because it is versatile: with its help, you can lay out the stove completely - from the firebox to the chimney... Its characteristics allow it to withstand prolonged contact with "live" fire. The variety of shapes of fireclay bricks facilitates construction work. To impart greater porosity to the structure of the product, aluminum oxide is added - this makes it possible for the material to accumulate and give off heat.

Fireclay brick perfectly copes with its tasks, but if it is made poorly, then you can forget about all its positive characteristics. To check the quality of a stone, there are several factors to consider.

- The brick should have a yellow tint, similar to straw - white color indicates insufficient firing. Such a material does not have the necessary strength and is not able to collect heat.

- A burnt stone will be covered with a glassy coating and does not bode well either. It is not easy to assemble a fireplace from such material - the solution does not hold on to it.

- If you knock on a brick with something hard, it will "respond" with a metallic sound - this means that everything is in order with the quality of the product.

- You can try to break the product - a real high-quality fireclay brick will not dust and crumble: its fragments will be large and clean.

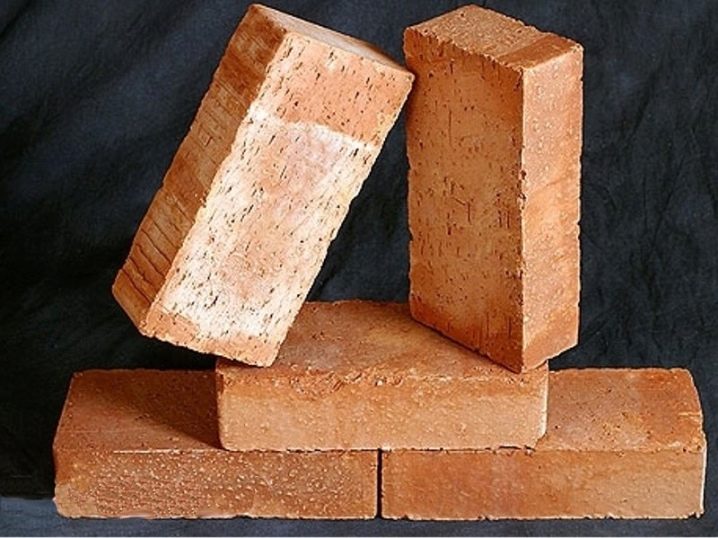

Ceramic

Red clay ceramic bricks are made by firing. His used in external places of the fireplace, not in contact with open fire... It is inferior to the fireclay product in many respects.

But there are also positive aspects: it is easy to process, because literally with a hammer it can be reduced to the required volume.

The size of the stone is 25x12x6.5 cm, fire resistance is 1200 degrees. Based on the legacy of the past, the industry produces products mainly in red. But recently, thanks to pigment additives, you can find yellow and white ceramic bricks on sale.

Quartz

This option is made from quartz sand and chamotte by firing. This type of brick is also inferior to fireclay, but outwardly the product looks much prettier. It is used for laying the stove in places associated with metal structures..

Quartz brick does not tolerate alkaline reactions, therefore it is not used for the foundation of the furnace, where lime can be used. Direct contact with the flame is also undesirable.

Quartz stone has proven itself well in the construction of chimneys. It has dimensions - 25x12x6.5 cm and fire resistance - up to 1200 degrees.

Kiln face brick

It is a kind of quartz product and used for cladding fireplaces, stoves, stationary grills and barbecues... It is produced with clear geometric shapes and a varied color palette.

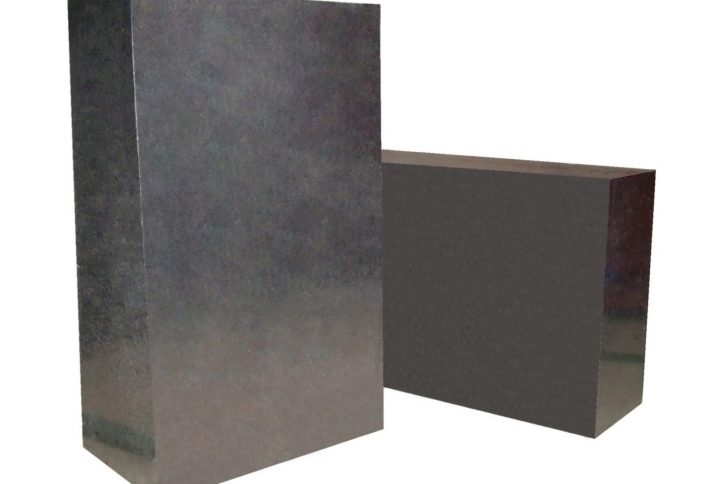

Carbonaceous

This type of stone is produced by pressing graphite or coke. He needed to create blast furnaces at metallurgical plants.

Basic

It contains magnesian and lime mixtures. Used directly in industry.

What is the best choice?

When choosing a refractory brick, you need to know what it is needed for: to build a stove in a house or a bath, to install a pipe or firebox. The type of material purchased directly depends on its purpose.

For the internal structure of the furnace and places in contact with fire, a stone with high fire resistance is selected. However, it must be porous in order to accumulate heat and heat the room for a long time.

The outer facing brick, on the other hand, should not be heated. His task is to have a beautiful appearance.

When decorating a fireplace with a facing stone, it is easy to choose a color that matches the interior. The industry presents a large selection of shades: from white to brown.

At the next stage of choosing a building material, it is worth paying attention to the points described below.

- It is imperative to check the markings and find out what types of work the material is intended for. There are frost-resistant products with increased porosity or fire resistance. To lay out the furnace, the product must contain at least 25% aluminum, and the refractory index must be 1700 degrees. There are universal solid types of bricks, for example, M200, which can be used for a firebox, supporting structures and cladding.

- It is necessary to check the material for defects: there should be no chips, dents, deformations. Each brick must have a clear geometric shape.

- Attention should be paid to the homogeneity of the structure - a uniform color indicates good quality. With the help of color, you can understand what kind of brick we have in front of us: unburned (light) or burnt (with shine). Such a marriage is not suitable for laying the stove.

- It is advisable to take all building bricks from one batch. If you have to buy more, then you may not get a perfect match.

- The product is checked by sound - a good stone should ring when struck.

When choosing bricks, it is better to have an idea of those products that absolutely cannot be used for a stove, fireplace, stationary barbecue and any structure associated with an open fire.

These include:

- hollow stone - it does not have sufficient density;

- raw - can soften, in contact with the solution or being in a damp room;

- silicate brick does not have sufficient heat resistance;

- no slip stone is used.

The choice of building material must be taken seriously - then the fireplace will truly warm, without losing its attractive appearance for many years.

How to cut?

If during the installation of the furnace it is necessary to cut a brick, then it is best to use industrial stone cutting machines... But since such a task is impossible at home, you can resort to a regular grinder... Cutting, abrasive or diamond discs are suitable for work (the latter will last longer).

Before working with a stone, you should make a pencil markup. There are two ways to cut a brick: dry and wet. When working with dry material, you need to be prepared for a large amount of dust and stock up on a respirator and goggles in advance.

A cleaner process of cutting the stone occurs if the building material is pre-soaked in cold water for half an hour. The brick will become softer, more pliable and will not annoy with dust.

Reviews of stove workers

Feedback and advice from experts relate to the technical characteristics of the material. If the stove is folded according to all the rules, high-quality brick is used, then it will not create problems even in the distant future.

Temperature limit

Stoves advise all material for stoves and fireplaces to choose heat-resistant, regardless of the place of use:

- for the device of the firebox - 1800 degrees;

- for interior walls - 700-1200 degrees;

- for chimneys and pipes - 700 degrees;

- for cladding - 700 degrees.

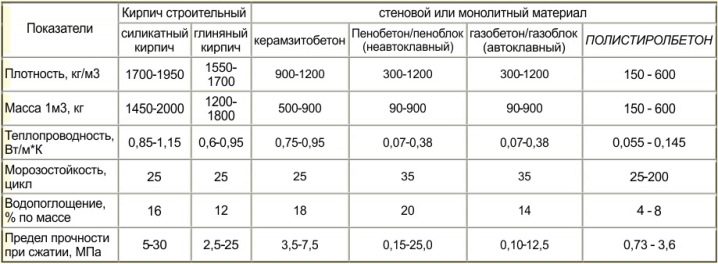

Thermal conductivity

Solid kiln brick has a high density and thermal conductivity, but each type has its own indicators under normal conditions (15-25 degrees):

- magnesite - 4.7-5.1 W / (m * deg) at a density of 2600-3200 kg / m³;

- carborundum - 11-18 W / (m * deg) at a density of 1000-1300 kg / m³;

- fireclay - 0.85 W / (m * deg) with a density of 1850 kg / m³.

Experts advise choosing a low thermal conductivity - this will make it possible to protect the materials adjacent to the structure from high heat. Fireclay brick is able to retain heat, but at the same time, its thermal conductivity is quite low. This material has the most positive reviews.

Resistant to aggressive environments

According to the reviews of stove-makers, we can conclude that fireclay bricks do not react well to an acidic environment, so you should not use it where there is a threat of contact with acid. Quartz brick suffers from alkaline reactions - it is not used in places where it is planned to work with lime.

Water absorption

According to experts, the water-absorbing effect of oven bricks is quite large. During firing, pores are formed in the stone, capable of receiving moisture from the external environment. If the building material is left outdoors, under snow or rain, it can gain 30% of its original weight. Therefore, you should pay attention to the place where the brick is stored and exclude its contact with a humid environment.

Information about the kiln brick will allow you not to be mistaken in the choice of building material. But even with theoretical literacy and a complete study of the topic, it is better to entrust the construction of the furnace itself to a professional. Mistakes in such a matter can cost the health and life of household members.

You can find even more tips on choosing a brick for a stove in the video below.

The comment was sent successfully.