Features of Torx screwdrivers

A screwdriver is an extremely necessary tool in solving not only everyday, but also professional tasks. Torx is a brand of a six-arm star shaped instrument.

Description

Textron developed the spline of this shape back in 1967, when the need for bolts with increased strength arose. It is this design that allows the fastener to be tightened more tightly.

Manufacturers of most of the equipment also appreciated the invention and began to use screws with such a head in mobile phones and household appliances. The lack of a suitable tool prevented the user from unscrewing the screws on their own.

The patented technology has been patented under the new name Torx Plus. The development became more reliable and was offered with an anti-vandal option.

Views

The tool, identified by the letters T or TX, is shaped like a six-pointed star. Inverted Torx External is indicated as E. The design feature of such devices is that in the fastener the head is made in the form of a star, while there is a recess on the screwdriver. Most often used in the construction of vehicles where it is necessary for the head of the bolt to be of a minimum diameter. Range of sizes from E4 to E44, but it does not match the usual T.

If there is a TR designation, then it is Torx Tamper Resistant, the main difference of which is the presence of a special pin in the center of the slot. A screwdriver has a special hole for such a bolt.

There is also a five-beam Torx on sale, it is designated as a 5-lobe Torx. In fact, this is a slot, which has the shape of a chamomile, it is widely used in technology from Apple, because it is highly reliable.

There is an improved version on the market with the Plus attachment, in which the ends of the star are cut off. It is referred to as IP. Size range from 1 to 100.

Another option - EP or External Plus comes in sizes from 1 to 42.

Dimensions (edit)

Screwdrivers of the same type have different slots in size. These parameters are set in accordance with the existing standards in millimeters:

- T1- 0.81;

- T2 - 0.93;

- T3 - 1.104

- T4 - 1.28;

- T5 - 1.42;

- T6 - 1.7;

- T7 - 1.99;

- T8 - 2.314

- T9 - 2.5;

- T10 - 2.74;

- T15 - 3.27;

- T20 - 3.864

- T25 - 4.43;

- T27 - 4.99;

- T30 - 5.52;

- T40 - 6.65;

- T45 - 7.82;

- T50 - 8.83;

- T55 - 11.22;

- T60 - 13.25;

- T70 - 15.51;

- T80 - 17.54;

- T90 - 19.92;

- T100 - 22.13.

Scope of application

Torx screwdrivers are essential not only in the automotive industry, but also in the dismantling of bicycles, ATMs, computers and other electronics. Even if the hex head screw has the edges of the groove torn off, you can safely unscrew the fastener using this type of screwdriver.

Most often, you can find such screwdrivers in repair shops, where they are engaged in disassembling cell phones, since almost all modern models are presented with bolts with splines in the form of a six-pointed star. There are such slots on some components for screws, for example, on hard drives.

Users unfamiliar with the official name tend to use the term "asterisk". When the development of a new tool was carried out, the first thing that was emphasized was reliability, which should be an order of magnitude superior to that demonstrated by bolts with other splines.

User manual

At the time of operation of such a tool, it is necessary to take into account the fact that the screwdriver must fit tightly into the existing hole. If the user sees that there is free space left, then the size of the head was not selected correctly. This is especially clearly seen on non-standard sizes, for example, the T47, which cannot be found in the usual set of tools, so it is selected like the T45, but the screwdriver dangles inside.

The tool needs to be pushed into the slot until it stops, sometimes the user has to resort to using an additional impact unit.

If you do not follow these two simple rules, then you can easily damage the grooves in the screw head.

How to choose?

When buying a quality screwdriver, special attention should be paid to marking. The numbers indicate the size. There is a table according to which the user is required to act.

The second point is the design of the handle on the instrument. It is better to choose with edges, plastic screwdrivers that will not scroll during operation. Hard plastic can scratch and rub your hand, if there is a rubberized pad - this is ideal.

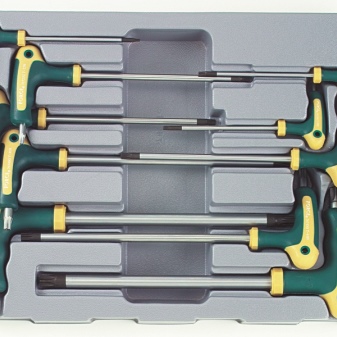

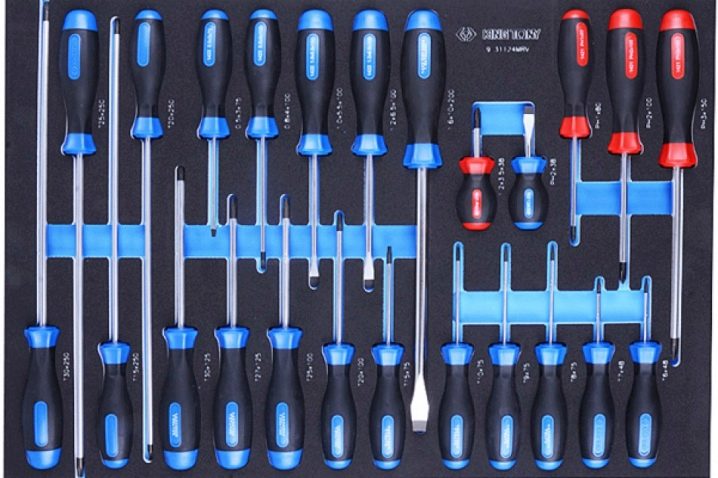

For those who have enough funds, professionals advise to immediately purchase a set of hexagonal screwdrivers. In the future, you will not have to buy screwdrivers, you just need to choose the required size of the nozzle. As a rule, such kits are supplied in special cases, therefore it is very convenient to store the instrument.

As for the material, the metal part of the screwdriver must be made of a high-quality alloy that has sufficient rigidity. Cheaper models will quickly bend, and there will be no benefit from such a tool, since it will not fit into the groove. The shape of the tip must match the tip of the screwdriver, otherwise you can either rip off the head on the screw or damage the tool. The peculiarity of hexagons is that they are designed for heavy loads.

The rods can be long or short, varying in thickness and hardness. Taking into account the state standard, the hardness of the screwdriver tip should be between 47 and 52 HRC. If less, the tool will bend, and more will lead to cracks. Only high-alloy chrome-plated steel meets all the necessary requirements. It is designated CR-V. A responsible manufacturer additionally applies anti-corrosion spraying to the surface, which increases the service life of the tool.

For an overview of Torx precision screwdrivers, see the video below.

The comment was sent successfully.