Characteristics and tips for choosing a hacksaw for metal

A hacksaw is a tool that every man should have in his home. The best and easiest to use version of the hacksaw will be the manual one, as it is versatile and unpretentious and copes well with wood, plastic and even metal.

In this article, we will take a closer look at what kind of tool it is, what constituent parts it has, what types it can be and how to use it correctly in certain cases.

Specifications

The hacksaws that exist today can be divided into categories according to two criteria:

- the nature of use;

- the presence of a drive.

According to the first criterion, they are professional and ordinary, and according to the second, manual and electric. If we talk about hand-held models, and, as a rule, they are more common, then regardless of their structure and type of application, they should be made according to the standards of GOST under the number 17270-71.

If we talk about electrical analogs, then they must comply with the standards of GOST IEC 60745-2-11-2014.

The most important characteristics of this type of hacksaw are the tooth pitch and blade size.

For models of various types, the length of the canvas can vary in the range from 30 to 70 centimeters. Here everything will rest on the physical size of the workpiece, which will be sawn. It is on it that a hacksaw with a blade that will match in length will be selected.

The pitch and direction of the teeth also need to be known due to the fact that, according to this indicator, it is usually determined with which materials a particular hacksaw blade can cope with in terms of hardness and thickness. As an example, teeth with a pitch of 3.5 millimeters will do an excellent job of cutting soft wood. And the 5mm version is suitable for hard rock. In addition, such solutions can be both two- and three-sided, which allows you to adjust the sharpness of the part responsible for cutting.

What does it consist of?

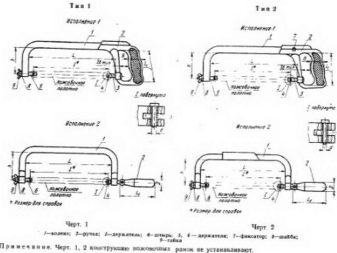

The tool in question has a very simple and straightforward design. If we talk about hand-held models, then they look like a bracket, between the ends of which a stretched canvas is fixed.

Usually, the tool also includes a frame and a hacksaw. Each of the constituent parts has its own subtleties and characteristics, and each of them is irreplaceable.

For example, a frame secures the saw blade. It can be created from various materials, depending on what you have to work with. For example, if we are talking about sawing some hard products, then it is better to use an option made of composites of a very strong type. Also, the frame structure will be in direct dependence on the conditions of use.

For example, if you have to regularly deal with cutting iron in hard-to-reach places, then it is better to buy a model that will have a blade tilt regulator for cutting or a not very large frame.

The handle also plays an important role during work. Convenience will depend on it especially for long-term use. The best grips are two-piece, which have special inserts made of soft but extremely strong rubber. Usually the handle is on the side or top of the tool.

A hacksaw device will be incomplete without a blade. It is a thin strip made of steel. Despite this, it is the most fragile part of this device.For this reason, you should be very careful and attentive while working. Otherwise, the canvas will simply break. This part has special wedge-shaped teeth.

When choosing a saw, you should pay attention to whether the teeth of the panel have been hardened... The fact is that this procedure can significantly increase the time of using the tool and its performance characteristics.

If it is required to cut hard metal products, then blades with not too large teeth are used, and soft options are processed with large incisors. It is better to purchase bimetallic or hardened solutions... They should be placed in a canvas frame so that the teeth are in the opposite direction from the handle.

Views

As you can already understand, the main purpose of such a device as a hacksaw is sawing metal products, forming grooves, seams, as well as cutting blanks along pre-prepared contours. In addition, thanks to it, you can work with materials such as plexiglass, plastic, ceramics, foam and wood.

If we talk about the types of this tool, then, as a rule, the following classification is used:

- home models;

- professional solutions;

- hand saws.

Home models are the simplest and most common option, which is suitable for the most basic household tasks. It is distinguished by its convenience and comfort. Usually, such solutions also have tension-type screw systems that are combined with a wooden handle.

Small hand hacksaw and will be in the form of a kind of bracket for working in hard-to-reach places. Then the rig will be cantilevered and fixed only on one side. Their design is even foldable. Usually, this category of hacksaws is only mechanical.

If we talk about professional models, they will differ in the presence of rubberized handles, which allows you to perform long-term work, as well as the ability to carry them out at a certain angle. Models of mini or mini-hacksaws seem to stand apart. They can be used in hard-to-reach places, they do not take up much space.

There are also network and battery hacksaws for metal, belonging to the segment of professional... The purpose of these models will be the same as that of manual counterparts - cutting metal objects in accordance with certain dimensions. It should be noted that such a locksmith or pneumatic model will have a distinctive feature - the presence of a drive that drives the blade for cutting due to the presence of an electric motor.

Hacksaws can be classified as mains saws, that is, they work from a conventional 220 volt electrical network, or rechargeable saws that operate on batteries. The latter are also called reciprocating saws.

Selection Tips

The tool in question, like any other, you need to be able to select. You should take into account not only the feedback and recommendations of the sellers, but also your own feelings when you pick up the tool.

It is better to avoid purchasing budget options and too expensive solutions when there is no way to understand why the price is so high.

The tool should be practical, so that during the movement in any direction and at different angles, it was possible to carry out the necessary work easily. For example, so that you can cut metal not only with ordinary movements, but also back.

When purchasing, you should first look at the frame. It can be different - for example, ordinary or made of some kind of durable composite-type materials. Such solutions are characterized by an extended service life and can cut even extremely strong metals and alloys. It will not be superfluous to pay special attention to the handle of the considered category of tools. The fact is that you will constantly need to hold on to it during the work.

If we talk specifically about the handle, then it should be as comfortable as possible and sit well in the hand. It should also have special hand rests.

In addition, the tool should not appear fragile and no part should wobble, but should fit snugly. This will significantly affect the integrity of the hacksaw and its ability to hold the blade in a certain position.

You can even consider, using the example of a 150 mm hacksaw for metal, what exactly should be of interest to you. Let's start with the shape of the teeth. Everything here will depend on the angle of the edge that is cutting. It usually ranges from 0 to 10 degrees.

The next moment is the pitch of the teeth. This moment will affect the thickness and hardness of the material with which this or that hacksaw can work. When analyzing this indicator, you should evaluate the category of material and the dimensions of the product with which you will have to work. It should be understood that when working on the workpiece, no more than three teeth should be affected at the same time... But this is provided that the cutting will occur at an acute angle.

The next important indicator is the length of the panel. Here, attention should be paid to the size of the workpiece and its volume. On average, a hacksaw blade can be between 30 and 70 centimeters long.... It is important to have straight teeth and the same surface.

When bending, the canvas should immediately return to its original shape. There should be no mechanical damage such as cracks or signs of corrosion.

A good option would be a small set of hacksaws, each of which will have a different purpose in order to saw a specific type of metal.

Exploitation

Now let's talk about how to properly use a hacksaw for metal. To work with her, you do not need to have any special knowledge. The essence of the work will be similar to its wood counterpart. The main thing here is to change the blade in time, choosing its specific type and pitch of teeth. Cutting thin sheet metal properly with such a tool will not be very easy.

The main thing is to ensure the normal movement of the tool back and forth. The tool should not wiggle. The maximum that can be observed is sagging.

First you need to figure out how to fix the canvas. If the panel is one-sided, then the teeth should be directed from the handle forward and downward. To install it, you need to loosen the tension screw, dismantle the old canvas from the pins, put in a new one and tighten it so that it literally rang from the click, like a guitar string. It should also not be fixed too tightly, so that the canvas simply does not break.... The best position can be found exclusively by experience, since everything will be individual for each hacksaw model.

Before the direct start of work, you should grasp the handle with your hand, and sometimes grasp the vertical edge, which is located opposite to the handle. Now you need to put the tool bar on the cutting line. Moreover this must be done strictly in the direction of the cut line. The angle of inclination should not be too large... The canvas should almost be on the part, at an angle of 30 to 45 degrees, so that noise and vibration are minimal. And the cutting line will be as flat as possible.

Cut across the metal at right angles only in emergency situations... The evenness of the cutting line will depend on the smallest angle of inclination.

It is better to do the first movements with not too much effort, so that the canvas enters the metal and does not slip from the line to the sides. It is necessary to carry out movements of the translational type and press the tool as tightly as possible to the material with which the work is being carried out. A when returning to its original condition, the pressure can be relieved... As soon as the canvas, as it were, clings to the metal, you can start working with it to the fullest.

The range of motion should be maximum, up to the edges of the canvas. The hacksaw arc should not hit the workpiece. Also do not cut in one place, otherwise the blade will very quickly be erased in some area and become unusable... The arc should be kept straight and not allowed to deviate to the sides.

The direction of cutting must be exactly the same as the surface of the hacksaw arc. Also, do not forget that sharp jerks can cause the blade to break.

Possible malfunctions

Most of the faults mentioned will be the result not so much of some structural defects as of improper use of the tool. For example, the canvas can simply split if it is tightened too tightly with the bolt into the frame.

Another point - if you cut in one place, then the hacksaw in some part will simply be erased, the blade will fail and become unusable.

Another fairly common malfunction is the physical breakdown of the hacksaw arc or blade. This is due to the fact that the person who works with the specified tool applies too much physical force while working. If it is not calculated, then it is very easy to break such a tool. Structurally, a hacksaw for metal looks extremely light and very easy to use.

If we are talking about electrical models, then there may be problems of a technical nature due to improper operation of the device or the presence of a factory defect. But the latter is usually observed quite rarely, if we talk about the products of some well-known manufacturers.

For information on how to properly saw with a hacksaw for metal, see the next video.

The comment was sent successfully.