Everything you need to know about worm gear clamps

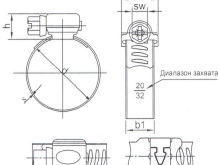

This article explains everything there is to know about worm gear clamps. They fully comply with the special GOST. It is necessary to familiarize yourself with the table of sizes of metal stainless clamps and a number of other subtleties.

Description and purpose

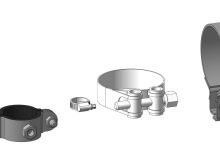

Worm gear clamps are one of the most important types of fasteners. They are mainly used for fixing pipes to the surface (and to the surface). You can also use these products to ground a metal hose. They include:

-

tapes;

-

screw part;

-

special lock.

Like conventional clamps, such designs have a specific GOST. It is also worth emphasizing that they have different sizes - and above all cross-sections. These diameters should be proportional, of course, to the diameters of the pipes. The maximum accuracy of the parameters is ensured by pressing, after which the clamp itself is joined to the branch pipe. This solution guarantees the reliability and durability of the entire assembly.

Most often, worm gear clamps are needed:

-

car manufacturers;

-

air duct manufacturers;

-

when creating ventilation systems.

Such products are supplied by Russian and German companies as well. Both countries guarantee the exceptional quality of their products. Modern worm gear clamps work reliably and provide excellent clamping tightness. The very high durability also testifies in favor of such models. The cost of worm gear clamps can vary greatly depending on the characteristics and brand.

The products guarantee excellent resistance to static and dynamic stress. Under heavy load, such hardware does not open. Absolutely extraordinary influences are needed for the worm clamp to be damaged. The required characteristics are provided only by the use of extra strong steel, which is mechanically strong, perfectly tolerates tension and resists wear. Tension bands are equipped with fixing slots, with the help of these slots the structure is mechanically closed.

Such holes are always rectangular; they are distributed over the entire surface of the belt. A similar product allows you to dock with each other:

-

ordinary wires;

-

electrical cables;

-

hoses made of rubber and other materials.

For the manufacture of clamps you need:

-

stainless steel;

-

zinc-coated steel;

-

carbon metal;

-

passivated alloys.

Species overview

The metal worm clamp can have different dimensions (diameters). It is additionally subdivided into types according to the type of belt: equipped with teeth or a notch. In such cases, they speak, respectively, of the rolling and notched options. 100% of worm products are made from steel, but the chemical composition of this steel predetermines a lot. So, galvanized steel hardware perfectly tolerates contact with aggressive chemicals. This is a fairly cheap product; it is he who is most often bought for arrangement:

-

water supply;

-

cooling systems;

-

gas pipelines of local or local importance.

But worm gear clamps can also be made of stainless steel grades. They are divided into:

-

easily magnetized;

-

anti-magnetic;

-

weakly magnetizable types.

Corrosion-proof structures withstand well corrosion processes and significant temperature fluctuations. They can be used in damp buildings and even outdoors in wet weather. A stainless steel hose clamp can be useful for gardeners and gardeners.But you have to pay a pretty serious amount for it. Combined options are more favorable in terms of price and quality ratio: the screw element in them is made of carbon steel, and everything else is made of a stainless alloy.

The screw sizes for worm gear clamps are also very different. This is determined by the geometry of the head:

-

with 6 edges;

-

with a straight groove;

-

with a cruciform groove;

-

with a collar.

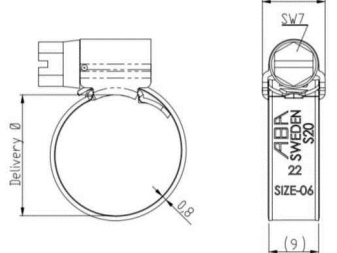

In some cases, a plastic wing screw is installed. This solution allows you to abandon the use of screwdrivers and carry out installation or dismantling manually. The length of the clamp tape determines the diameter, and can be either 0.8 cm or more than 16 cm; within all this diversity, distinct groups are distinguished. Narrow designs are used in conditions of strong vibration, wider designs are used for hoses that should not be subjected to excessively powerful compression.

In terms of resistance to loads, clamps are usually divided into standard and reinforced types; the presence of corrugated teeth set at a certain angle, which are more reliable than perforated notches, is welcomed.

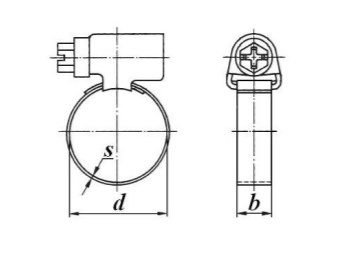

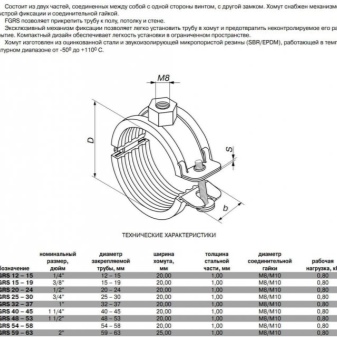

Dimensions (edit)

The most commonly used sizes in everyday life are shown in the table below.

|

Group |

Total tape length, cm |

Width of the same tape, cm |

The highest permissible load level, H |

|

10-16 mm |

2,3 |

0,9 |

1300 |

|

12-22 mm |

2,3 |

0,9 |

1300 |

|

20-32 mm |

2,6 |

0,9 |

1300 |

|

25-40 mm |

2,6 |

0,9 |

1300 |

40–56 and from 40 to 60 mm - tape length - 2.6 cm, load - up to 1600 N; For groups of clamps from 8 to 12 mm and from 16 to 27 mm, the tape length is 2.3 cm, and the maximum load is 1300 H. Other size categories:

-

87–112 - 2.6 cm and 2600 H, respectively;

-

149-162 - 2.6 cm and 2600 H, respectively.

Clamps of even larger size are occasionally used. But they are mainly used by professionals. When choosing for a specific task, first of all, you should pay attention to the smallest and largest diameters. Failure to take these properties into account results in weak compression or installation difficulties.

As for the permissible load, it is of interest mainly to specialists who create precisely normalized connections.

Features of marking

Of course, worm gear clamps are marked with their size group. But no less important is the indication of the material used. If the index is W1, then the hardware is made of galvanized metal. Marking W4 shows the use of stainless steel. But with W2, everything is much more interesting: the tape is made of a stainless alloy, and the bolt is made of ferrous metal (but at the same time it is covered with a protective zinc layer).

If 1L 25-40-6 N is written on the product, then this means sequentially:

-

actually, the worm type (1);

-

belonging to the light series;

-

range of diameters (25-40);

-

actual width;

-

made of stainless steel (when using ferrous metal, this index is simply discarded).

Operating tips

The main set of requirements for worm clamps is fixed in GOST 28191, in force since 1989. The recommendations of the standard are mandatory when joining a clamp, a hose and any kind of tubing. Important: for high-quality products, the joining with the tape should be at the same level. This requirement should be met by all manufacturers without additional welds or rivets. If this position is not met, you can fear deformation of the hose or sleeve during use.

Lightweight clamps are suitable for applications where there is no strong vibration. But at the same time, tapered products equipped with bolts can be used precisely when there is an increased risk of vibration. You can tighten the fasteners using hexagons or screwdrivers. The tightening range can vary from 0.6 to 7.6 cm. Each time it is better to find out more detailed information directly in GOST.

The lamb clamp is very convenient and practical. It can be put on and off without additional tools. Do not use fasteners if they have burrs or other manifestations of deformations that could impair performance. It is recommended to check the labeling before use.The sizes of pipes, sleeves and other connected products are selected in advance.

By default, worm gear clamps are designed for an operating pressure not exceeding 7 MPa, including probable critical situations. The equivalent value is 70 atmospheres (it must be taken into account, since in a number of sources pressure is measured in atmospheres). For wire types of worm gear, the allowable pressure does not exceed 0.16 MPa or (otherwise) 1.58 atmospheres. Placing the fastener on steel pipes is acceptable even if there are clear signs of corrosion and minor cracks.

Worm-type clamps are very helpful in case of so-called pipeline fractures. This is, of course, not about the household variety, but about highly specialized models that are mounted on walls and ceilings. Clamps can be installed on pipes made of:

-

cast iron;

-

reinforced concrete;

-

polypropylene;

-

ferrous and stainless metals.

It is allowed to use them for copper pipelines. True, in this case, it will be necessary to carry out welding work for a fairly reliable docking. Clamps cannot be used on a cross joint. It is impractical to use them in areas where pipes are bent; it will still be ineffective. The installation of worm structures itself is carried out after the completion of the assembly of the pipe line or pulling the hose, and not during operation.

In order not to make mistakes during installation, markings are made in advance at the installation points of the clamp. In these places, holes are drilled into which you can insert self-tapping dowels and other fasteners with a certain diameter. Structures made of carbon or stainless alloys are more versatile than simple ferrous metal. It is advisable to choose products with a rubber gasket. They are less noisy and less damage to the serviced pipe.

For everything you need to know about worm gear clamps, see the video below.

The comment was sent successfully.