Primer-enamels for rust: types and overview of manufacturers

Unique coatings - primer-enamels, are able to protect and restore metal products from rust, in particular, significantly extend the life of car surfaces, especially where a climate with pronounced seasons, unstable weather and an abundance of precipitation prevails.

Appointment

Anti-corrosive primer enamels are used to create a protective and decorative layer on a clean or rust-damaged area of metal. They create protection against the effects of dampness, fresh and salt water, rain, snow, hail, therefore they are well suited for new or previously painted metal fences and roofs, doors and gates, fences and gratings, various technical and decorative products, equipment and structures located indoors and outdoors, parts of cars and boats.

Varieties

There is a whole range of protective paints and varnishes. For example, alkyd-urethane enamels, often used for outdoor coating of concrete, metal and wood. A wide range of applications for epoxy enamel, characterized by durability and resistance to weathering - from flooring to painting external walls and roofs. Polyurethane enamel is renowned for its use on concrete and wood floors. Alkyd or acrylic enamel is renowned for its variety of types and versatility.

A variety of anticorrosive primer-enamels are used to protect metal from rust, have a complex chemical composition and are subdivided into:

- insulating;

- passivating;

- transforming;

- phosphating two-component;

- protectors;

- inhibitory.

Insulating primer enamel forms a layer that protects the metal from moisture and oxygen. It has increased heat resistance and is good for structures in the open air or in water. The passivating agent is capable of slowing down the corrosive process and is well suited for conditions with high humidity. Converters, which include phosphoric acid, interacting with rust, form a reliable phosphate film and partially reduce the metal. Phosphating two-component, in addition to phosphoric acid, containing and passivating substances, have excellent adhesion (adhesion) to the surface and are suitable for processing galvanized metals.

Protectors are equipped with metal particles, when dry, they form a strong metallized coating, are economical in consumption and are recommended for processing products in contact with water. Inhibitors are distinguished by deep adhesion to damaged metal, high anticorrosive properties, increased consumption and are well suited for decorative painting.

By their composition, many of the above means are of the so-called 3-in-1 primer-enamels, which will be discussed below.

Composition and specifications

Some primer enamels compare favorably with others in ease of use due to their multicomponent nature. They contain, in addition to solvents, various pigments and fillers, three main groups of substances:

- rust converters;

- anti-corrosive primer;

- outer decorative layer.

Therefore, these paints and varnishes are called 3 in 1 primer enamels.And thanks to the uniform and unique consistency, instead of three consecutive coats, only one is required. The owner of 3 in 1 enamel is exempt from the cost of primers and putties. Some of their other attractive features can also be noted:

- heat resistance of the finished layer (withstands the range from + 100 ° С to -40 ° С);

- evenness of the treated surface;

- immunity of the coating to inorganic and organic substances (mineral oils, weak solutions of salts, acids and alkalis, alcohols, etc.);

- no need for thorough preparation of the painted surface (complete removal of rust is not required);

- relatively low consumption and good hiding power (ability to cover the color of the surface);

- fast drying (within about two hours) and durability of the coating (up to 7 years outdoors, up to 10 years indoors).

The consumption of such enamels is 80-120 ml / m2 (one layer). The thickness of one layer is approximately 20-25 microns (0.02-0.025 mm). There is about a kilogram of composition per seven square meters of surface. Externally, the coating is a thin continuous and uniform uniformly colored film. Suitable surfaces for painting are products and surfaces made of stainless steel, cast iron, some non-ferrous metals such as aluminum, copper and zinc.

In the composition of rust paints, among other elements, various fillers can be presented. Some protector enamels may use metal particles to create strength and texture in the final finish. For example, the so-called hammer paint for rust is known, which contains aluminum flakes, which, when dried, create a texture reminiscent of the effect of hand hammering on sheet metal.

Manufacturers overview

In Russia, the production of paints and varnishes and household chemicals is quite common. In particular, among the suppliers of primer enamels 3 in 1 stand out:

- Saint Petersburg mark "Novbytkhim"... Among the products of the company there is a quick-drying passivating primer-enamel for rust 3 in 1. It is used for the protection and painting of intact and rust-damaged metal surfaces. It has transforming properties, anticorrosive primer and decorative enamel, which simplifies the painting process. It is widely used for painting large items with a complex structure.

- Moscow firm LLC NPO Krasko offers a quick-drying inhibiting shock-resistant semi-matte primer-enamel for rust 3 in 1 "Bystromet" with one-layer protection, as well as polyurethane "Polyuretol" - chemically, moisture and frost-resistant glossy tread high-strength primer-enamel 3 in 1 with the effect of "micro-titanium" (the presence of titanium particles in the paint creates a significant resistance of the created surface to all kinds of physical influences).

- LLC "Kaluga Paintwork Plant" manufactures transforming enamel-primer for rust PF-100. Made on the basis of alkyd-urethane varnish, it has the properties of enamel, rust remover and primer.

A two-layer coating is capable of long-term demonstration of excellent protective and decorative properties in a changeable temperate continental climate.

- Novosibirsk firm "LKM Technologies" represents "Pental Amor" - a primer-enamel 2 in 1 (external finishing enamel in combination with an anti-corrosion primer), used for metal surfaces inside and outside the premises, as well as transforming primer-enamel for rust 3 in 1 "Corroed", which is intended for repair painting of various objects (bridge spans, hangars, power transmission line poles), products with a complex structure (shaped fences), capacities used in agriculture.

- FKP "Perm Gunpowder Plant" produces in a variety of color palette heat-resistant primer-enamel "Acromet", which has good adhesion to the processed material, combines the capabilities of the primer and the final coating with excellent external parameters and provides reliable protection of the coating from external environmental influences.

- CJSC "Alp Enamel" (Moscow region) offers a quick-drying, weather-resistant and chemically resistant 3-in-1 primer-enamel "Severon", designed for use in areas with a harsh climate and unstable weather.

- Company "Yaroslavl paints" creates a primer-enamel for rust 3 in 1 "Spetsnaz" with high resistance to the atmosphere in an industrial zone, used for the transformation and painting of bulky structures with a complex structure, on which the dismantling of the previous coating is difficult (fences, gratings, bridge structures), as well as for restoration painting of passenger car parts (bottom and fenders).

- Yaroslavl company JSC "Russian Paints" manufactures Prodekor primer-enamel, which is intended for painting factory buildings, products of complex design, on which cleaning of the old coating is difficult, as well as for repair painting.

- An interesting hammer paint for rust is presented by a Polish brand Hammerite. This paint protector contains metal particles that, when dried, create a pearlescent hammer-effect pattern on iron.

Application Tips

It should be noted that the effective use of rust primers is only suitable for relatively small damaged areas. More extensive restoration work is needed for larger areas.

To choose the correct enamel, it is reasonable to consider the following points:

- surface material (for example, for galvanized metal, it is preferable to choose phosphating two-component enamels);

- the nature of the surface (if the surface is of a complex configuration, then you should take enamel with high adhesion; in the case of a heavily rust-damaged surface, you need to remember that the consumption of enamel will increase; if there are difficulties in removing old paint, then it is useful to take enamel of the "Spetsnaz" brand);

- air humidity (in humid climates, insulating or passivating enamels should be used);

- air temperature (for example, in low temperature conditions, it is better to use quick-drying compounds);

- the nature of the product's use (if, for example, it is subjected to mechanical stress, then enamel-protectors of the "Polyuretol" type are better suited);

- decorativeness of the product (the desired color, for example, black for the grille; matt or glossy gloss of the corresponding enamel).

It is better to stir the enamel before applying so that all its components are evenly distributed. If the consistency seems too viscous, then various solvents, such as xylene, can be used to dilute the composition. It is necessary to prepare the surface to be treated, namely:

- clean it from dust or wash it with water from dirt;

- dry in order to achieve full adhesion to the enamel and to avoid peeling of the coating;

- in case of oil contamination, degrease the surface, especially places damaged by corrosion, for example, with white spirit (and then dry it);

- remove cracked parts of the coating;

- if it has already been coated with varnishes or paints, it should be cleaned with a fine abrasive tool (eg sandpaper) to a matte surface.

If there is rust, then it is necessary to remove only its loose part, for example, with a metal brush or a spatula. The thickness of the remaining dense rust should not be thicker than 100 microns. Otherwise, there is a chance that the painting will be of poor quality.

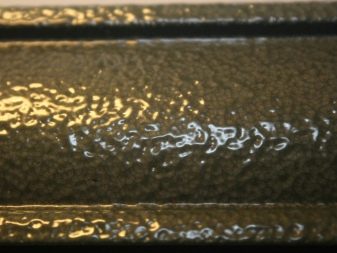

It is imperative to pay attention to the fact that the imposition of a primer-enamel is unacceptable on a surface that has previously been treated with nitrocellulose agents, for example, nitro lacquer.Then the old coating can bulge. If in doubt, you can test it: evenly apply a little enamel on a small area and wait an hour. If the surface has not changed, you can continue painting. If swelling occurs, you need to remove the damaged coating using special washes for paint and varnish products.

Thus, when working with 3 in 1 primer enamels, it is not necessary to remove all old paint and rust from the surface. A primer is not needed either - it is already contained in the enamel.

For a more effective and reliable painting, it is necessary to observe some indicators. The relative humidity of the air during painting should be about 70%, and the air temperature should be in the range from -10 ° С to + 30 ° С.

Storage and transportation of enamel can be carried out at temperatures below 0 ° C, always in carefully closed containers, away from children, the sun and heated appliances.

Application is possible in various ways and tools: you can act with a brush, use a roller, dip the part into the composition, cover the product with a spray. Use rubber gloves to protect your hands. It is better to use wide and thick brushes (this will allow to distribute the composition more evenly) made from natural bristles (this will keep the brush from aggressive paint substances). When spraying, use a metal spray gun without plastic parts that could be damaged by the enamel's anticorrosive substances. Spraying with an aerosol is beneficial when a very small surface area is painted.

The paint is applied in one, two or three layers. It takes forty minutes to completely dry each layer.

To create a quality surface, it is best to apply at least two coats. For general drying of the multi-layer coating, you should wait a week.

Enamels are not recommended for interior decoration. Anticorrosive agents are very toxic, therefore, when working inside other premises, you should use a respirator and ensure good ventilation.

The undoubted advantage of primer enamels is, among other things, its relatively short drying time under various conditions. This saves time spent on work. The disadvantage of this product is a strong unpleasant odor, which persists for quite a long time.

The use of primer enamels in the automotive field deserves a separate discussion. After all, they create a more durable and reliable coating than other means, and therefore this paint and varnish material is most often used not for painting the outer body of the car, but for its parts that are most in close contact with moisture, mechanical action of sand, stones, road salt. Soil-enamels 3 in 1 are actively used in painting the underside of the car and the inner parts of its wings. For example, 3-in-1 rust paint for cars from Novbytkhim, which demonstrate:

- effective protection against water and mineral oils;

- excellent adhesion to the base;

- prevent rust growth;

- good covering ability;

- fast drying when painting;

- relatively low cost of the product;

- ease of use;

- pigment quality that gives the car surface attractive decorative properties (however, due to the limited range of colors, it is sometimes difficult to achieve uniform body tinting).

To ensure the resistance of the future coating of automotive parts to atmospheric and mechanical influences and thereby increase its durability, it is recommended to apply at least three layers of the composition.

A video tutorial on applying the SEVERON primer enamel with a velor roller, see below.

The comment was sent successfully.