Primer: types and scope

DIY repair is a difficult but doable task. The key to success is to get the job done without haste and not heed the advice of the professionals. The specialist knows that the necessary stage of absolutely any work, whether it be finishing the walls in the kitchen or leveling the floor in the bathroom, begins with treating the surface with a primer. The scope of this tool in repair is very wide, and for each type of work there are different types of primer.

What it is?

For unenlightened people, the word "primer" evokes various associations. At best, it is considered a solution for treating wooden surfaces before painting. At worst, they are not distinguished from putty. In fact, this is a substance with a complex composition and a wide range of actions.

Depending on the type of work surface for which a primer is needed, its composition is slightly different, but most primers are a combination of the same components:

- Liquid component. Most often it is water, which is already present in the composition of the substance. In some cases, the soil is sold as a powder mixture and water is also added to it in the proportions indicated by the manufacturer. The liquid in the composition provides easy application to the surface and the ability of the substance to penetrate into the deep layers of the material.

- The foundation. The percentage of this substance in the composition is quite large. The base helps the primer not to evaporate too quickly, reacts with water, so that the liquid composition is distributed over the processed material in a thin uniform layer. The base can be polymer, organic or mineral. The most commonly used are widely used gypsum, cement, lime.

A modern primer can also be based on synthetic substances. Their list is more extensive, but not all of them are allowed by GOST.

- Coloring pigments. Not required for all types of primer. Most often the soil is neutral or transparent. But for processing pure wood, it is recommended to use a white or light-colored primer so that the surface is clearly visible. Some primers have a pinkish or grayish tint. It is also intended for wood that will be painted a darker color than white.

- Adhesives. They provide traction.

- Adsorbent (film-forming) substances.

- Bitumen, oils, resins.

- Hydrophobic (water-repellent components).

- Anti-mold additives.

- Antibacterial substances (insecticides, fungicides).

- Polymers and copolymers.

- Insulators.

The exact composition determines the purpose of the primer.

Its use is recommended for the following purposes:

- Improved adhesion (adhesion) between the working surface and the leveling layer. Plaster, putty, oil paint and various enamels are often used as a leveling coating. Also, cement, concrete, gypsum mixtures can serve for leveling.

- Deep penetration into the interior of the finishing material. It would seem that the function is of questionable usefulness, however, it is necessary for working with old surfaces.Penetrating deep into the wood in the floor or on the walls, the primer, as it were, holds its fibers together, preventing peeling and cracking.

- Corrosion protection of metal surfaces. As you know, metal is coated with paint not only and not so much for beauty, but to protect it from corrosion. The paint will have to be renewed much less often if a protective layer of primer is applied under it. An additional advantage of the primer - the enamel will lay smoother.

- Antiseptic action. Some finishing materials contribute to the greenhouse effect, the cultivation of fungi and microorganisms, which affects the appearance of the decoration and the health of the inhabitants of the house. For example, black mold that appears from dampness is a terrible toxin and depressant. Its appearance is highly undesirable, and a primer with antibacterial additives helps to protect the walls. It is useful for treating wooden surfaces, as well as walls for drywall, siding, liquid wallpaper, decorative plaster, other dense materials and a floor under a dry screed.

- "Revealing" of the tree structure. This technique is used for wooden surfaces, when they are not supposed to be covered with a thick layer of paint or other decorative material. The primer accentuates the natural grain of the wood, and lacquer is perfectly applied on top of it. There is also a ready-made primer mixture with the addition of varnish.

- Saving liquid finishing materials. For example, when painting wood, a layer of primer prevents the wood fiber from absorbing the paint. When gluing wallpaper, it reduces the consumption of glue.

- Moisture protection. It is necessary in rooms with a damp microclimate. At the same time, in damp rooms, the primer is used both for decorative finishing, and in some cases on top of it.

- Prevention of fluid loss when pouring the floor screed. One of the reasons why a cement or concrete screed for leveling the floor cracks when it dries is the "escape" of the liquid into the floor layer. Priming the sub floor is not only necessary, but necessary. At the same time, you should not feel sorry for the primer. The price for it is much lower than for pouring the screed, and a high-quality coating can save the leveling layer from cracks. The primer is applied to the floor until the small “puddles” no longer soak up before our eyes.

- Reprocessing. Secondary primer application is never superfluous. It is actual to use it over the leveling layer, before applying wallpaper or other type of decorative material. The second layer of soil not only protects the working surfaces from vapors, soot, soot, but also makes it easy to remove the finishing material during the next repair.

In a new building, when finishing is done for the first time, during the entire cycle, the primer can be applied three times: before leveling, along the rough leveling layer and over the final layer.

Peculiarities

A characteristic feature of a quality primer is compliance with production conditions, which are regulated by GOST. Manufacturers add various substances and compounds to the composition, and some of them can be very effective, but not safe for health. Only products that meet all the requirements of the standard can be used indoors.

GOST provides for the following soil characteristics:

- The color of the substance after it dries. Before application, the primer is usually white, milky, pinkish, cream, and then becomes transparent, unless otherwise specified by the manufacturer. Some species have a richer color. Shades are not subject to standardization.

- External characteristics of the soil after drying. According to the standard, it should be an even, uniform, matte or semi-glossy film.

- Storage conditions and the presence of sediment. The substance is stored in a closed container, away from sunlight and moisture. As a result, no significant sediment should form.Only an easy-to-mix layer and a thin film are allowed.

It is possible to use the soil after long storage only if it has retained all its qualities, in accordance with the standard. The warranty period is no longer than 6 months.

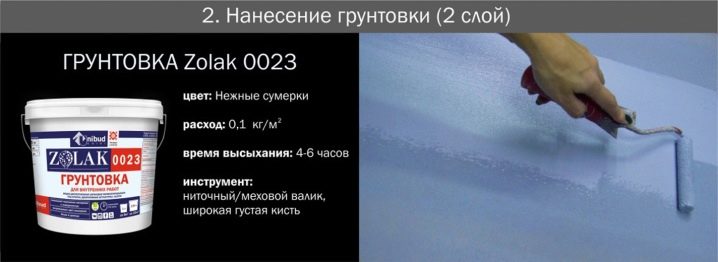

- Soil consumption. For one layer, it is calculated from 60 to 100 grams per square meter.

- Resistant to grinding. After this procedure, there should be no greasy marks on the "skin", and the primer remains smooth.

- The density or viscosity of a substance. It is difficult to determine without a special device, therefore, when choosing a tool, you need to focus on the information sticker. The standard figure is 45. Deviations are allowed.

- Possibility to thin the primer with a solvent. Maximum - 20% substance on 100% soil.

- The proportion of non-volatile (non-volatile) substances. It fluctuates within 53-63%.

- Drying time and indoor temperature conditions: 24 hours at 20-22 degrees Celsius.

- The hardness, elasticity and flexibility of the film, the degree of delamination - within one unit.

- Impact resistance - 46-50.

- The degree of adhesion is no more than 1.

- Resistance to alkaline and chemical substances - 24.

- Safety standards for working with soil. GOST recognizes it as a toxic material that is easily flammable, therefore it is recommended to work with soil in a ventilated area, using personal protective equipment, away from fires. Apply the substance with a brush or paint spray.

Also, when choosing a primer, it is important to take into account what is not spelled out in the GOST. Namely: the advantages and disadvantages of the substance.

Consider the pros of different types of primer:

- A wide range of primer compounds makes it possible to solve various repair tasks, and to protect the internal and external surfaces of the room from the influence of the environment.

- Wall treatment guarantees a strong adhesion of the finishing material to the work surface.

- Low price.

- It helps to save on the amount of adhesives and liquid decorative materials for finishing, since the surface of walls, ceilings or floors after processing does not absorb the product.

- Extends the service life of finishing materials.

- Facilitates their removal from the surface during repeated repairs.

- The primer in the color of the topcoat gives a more durable and "dense" shade.

- Increases the biostability of materials.

- Makes the structure of the work surface uniform. In some cases, this is extremely convenient. For example, old plaster does not need to be removed to apply a decorative layer. The primer will make its surface smooth and monolithic.

- Most species are odorless.

- Protects decorative finishes in rooms with a humid microclimate.

- Consists of components safe for health.

- It is extremely easy to use and ready to use immediately after purchase.

Disadvantages of a primer:

- High consumption when working in a room with an impressive area.

- The properties of the primer are not cumulative, they do not double or triple with an increase in the number of layers, but you can also "overdo it". In this case, the primer will not improve adhesion, but, on the contrary, will minimize the quality of finishing work.

- Dries completely in 24-48 hours

- There is a risk that the product will fall on the surface in an uneven layer.

- Some types of primer, which cannot be replaced with a universal composition, have only a rich red, black or brown color and it is very difficult to cover them with a light decorative finish. The consumption of material increases, the cost of repairs increases.

- If odorless, some primers are considered toxic. Some of them have a pronounced chemical aroma.

- It is not a fireproof material.

The characteristic features are determined by its type.

What types are there?

The classification of primers is made according to several criteria:

By the composition of the substance

There are about a dozen varieties.

- Acrylic. The composition of the product allows the surface to "breathe", despite several layers of soil. It is used on a variety of materials, from concrete to wood, according to the manufacturer's labeling. There is also a versatile acrylic primer.

- Mineral. The base is made up of common materials such as cement, which makes it suitable for use on a variety of surfaces. Works especially well on porous materials of mineral origin, limestone and plaster. Resistant to moisture and sunlight.

- Alkyd. A material that includes polyvinylchloride, polyurethane, polystyrene, acetate components and dyes. By their nature, they are practically universal, they are even used for glass. Enamel, polyurethane and glyphthalic primers are all varieties.

- Epoxy. At the heart of the composition, as it is already clear from the name, is resin. In addition to them, the composition contains additives of chemical origin. The surface after processing acquires a dense matte or glossy film, which is maximally resistant to aggressive environmental influences

Distinctive features - resistance to high temperatures and damage. Mostly metal products are processed.

- Silicone. Concentrated binder with the ability to give the most durable coverage. Ideal base for silicone based paints. Working with it requires caution, since the fumes of the substance are toxic. It is relevant for work outside residential premises, where enhanced protection from the negative effects of climate and environment is required.

- Silicate. The synthetic base is potash glass. Such a primer is used mainly when working with the facade of architectural structures. It can be brick, concrete, with plaster finishing. It is most effective in tandem with silicate paints.

- Latex. A collective name for a group of materials, the main property of which is to fill pores and cracks on the surface of walls, ceilings or floors. A significant share in the component composition belongs to a sticky substance - latex. It is he who performs the function of the primary leveling layer and improves the adhesion of the remaining layers to the working surface. Universal formulations are made on the basis of latex.

- Quartz. The basic component in the composition is quartz sand. Additional components - water-dispersive group of materials. Water repellency and rough surface during processing become the main properties of the primer. It works best as a means to increase adhesion between the finishing material and walls.

An additional plus of soil with sand is its color. In the right shade, close to the finish, it provides a beautiful decorative effect. There is a harmony between the absorption and reflection of light, and the shade of the paint is revealed as effectively as possible.

- Shellac. It has an unusual composition: milky juice obtained from insects and methyl alcohol. Together, they give the effect of a varnish stain. Such compositions are actively used in wood processing, as they work like the well-known drying oil, but do not have a strong odor and do not leave oily stains on the wood. With their help, the cut points of knots on boards, logs and beams are processed in order to prevent the release of resin.

- Phosphate. Phospho-primer is a mono-component material used exclusively for various metals. Mainly in works on the facade of the building, due to the unique ability of the primer to remove rust and fight against its appearance.

- Bituminous. The general name for a number of primers whose main purpose is to protect the floor covering. It is used under wooden floors, under various types of flooring, under floor screed (wet, semi-dry, dry and prefabricated).

The composition can vary greatly, depending on the accompanying components.These include: gasoline, rubber waste, mineral mixtures, water, polymers. The primer is highly toxic, requires work in a ventilated area with a respirator.

By the degree of penetration

- Surface action. Such compositions form a dense film on wood, concrete, brick, limestone, stone, glass and other materials. It fills the porous surface and microcracks, smoothes them before applying putty, gives a slight roughness, due to which the adhesion of materials is improved. At the same time, all the substance remains on top, without seeping into the deep layers of materials, which is not optimal in all cases.

- Deep penetration. It differs from surface soils in that the composition contains substances of a finer fraction, which are able to penetrate into some materials, for example, wood and its derivatives, to a depth of 15 millimeters. Their surface is smoother, and an antibacterial substance is necessarily present among the components. It protects the inner layers from decay and destruction. It is actual to use on wood, drywall, plaster, concrete, gypsum and brick surfaces, cinder block, cement.

By appointment

- Wood. Wood is widely used in construction, due to its aesthetic and operational characteristics, but it is capricious in its care and requires careful selection of materials for processing. The main problem in wood finishing is a high degree of absorption of dyes and adhesives by wood fibers.

In order to save money and for better distribution of the substance, a primer is needed that prepares the surface completely. It can be an oil-based, acrylic, mineral-based primer. The main requirements are light color, the ability to penetrate deep into the fibers, the presence of antifungal impurities.

- On plaster. The plaster is susceptible to moisture, soot, mechanical damage, so the layer must be dense, well-protecting, water-repellent and containing antibacterial components. Penetration rates vary.

- For metal. The main requirement is protection from moisture and corrosion. One-component formulations are suitable, for example, phosphate or shellac.

- Concrete contact. It is mainly used for the treatment of floor slabs. Provides protection against moisture penetration deep into the ceiling. Suitable compositions for porous surfaces based on latex, silicone and silicate, universal primers, bituminous solutions.

- Universal. It is used if the material is not specific, and the microclimate in the room is not damp. The processed material can be drywall, wood, plaster, fiberboard, chipboard, plywood sheets and OSB boards.

At the place of use

- For outdoor decoration. Solutions with high resistance to temperature effects, ultraviolet light, moisture, mechanical stress. They process the facades of the building. Indoors, such dense coatings will be superfluous. Because of them, the walls stop "breathing", there is a risk of the greenhouse effect.

- For interior work. These are all primers that, according to GOST and specifications, can be used indoors.

By properties

- Water repellent. Forms a protective layer in damp rooms. For example, the walls are processed with it before laying the tiles in the bathrooms.

- Antiseptic. Indispensable when working with wooden bases and when processing old buildings.

- Firming. Primer for "plugging" micropores on unstable substrates such as plaster, lime, putty.

- Anti-corrosive. Required where there are metal fragments or solid metal surfaces. Prevents rust and material decay.

- Adhesive. Improves the adhesion of materials to the substrate on different planes. It happens for walls, ceilings and even floors.

- Final. Completes the cycle of rough finishing works, preceded by decorative finishing.

- Universal. Used for surfaces that combine several characteristics.

Colors

The color of the primer is of fundamental importance. A correctly selected shade, suitable for the shade of a decorative coating, solves several problems at once.

- Checking the uniformity of the primer layer. The more contrasting the colors of the roughing surface and the primer, the more obvious any flaws. This is very convenient in order to eliminate all defects even at the stage of preparation.

- Improving the quality of the topcoat. There is no doubt that a white base for white wallpaper (especially thin) is more suitable than a brown one. Likewise, a gray primer allows the gray paint to develop to its fullest.

- Saving on the amount of finishing materials. When it comes to renovations in a residential area, where it is difficult to find a room less than 8 square meters, the number of paint coats required for decorating walls can both significantly reduce and significantly increase the cost of repairs.

- Saving time. Minus an extra layer of paint - minus an extra half day of physical work with a roller and a step-ladder against the wall.

- Extending the service life of the coating. At first glance, this is an insignificant detail, however, in practice it is almost the most important. If the color of the primer is matched to the paint on the walls, then instead of mechanical damage (bumps, chips, scratches), where the decorative layer will suffer in the first place, the damage will remain invisible. When using different shades, the appearance of the finish will deteriorate faster. Whatever one may say, but the difference will be noticeable even between two light shades.

- Provides a presentable look as a final coating. For example, when in some interiors it is important for stylistics to preserve the texture of wood, stone or lime covering. A varnish primer is used for wood and matt for other surfaces.

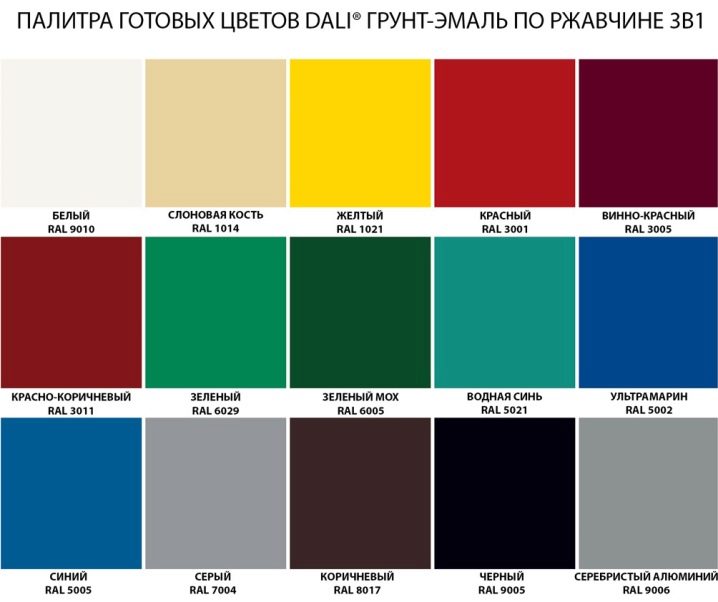

Various manufacturers offer rich color palettes to choose from. Among light primers, white, biscuit, milky, beige, lavender, cement gray, silver gray, pistachio color, spring shades of yellow, green and pink are popular.

From the more saturated under the paint, you can pick up a brown primer, blue, green, terracotta, vanilla, Prussian blue, Marsala, purple. The darkest are graphite and black.

Separately, it is worth highlighting primers for the finishing coat, which are dominated by natural natural shades: pear, chestnut, mahogany, teak, oak, walnut, rosewood, birch.

How to choose the best one?

To choose the right primer, you need to build on several aspects.

- The first point of assessment is that renovations are planned inside the building or along its facade. Then, the protection of the treated areas from moisture, temperature, ultraviolet rays, and mechanical influences is assessed. Based on these parameters, choose a primer for outdoor or indoor work and determine the degree of coverage of the material. The less severe the climatic and microclimatic conditions, the lighter the primer should be.

- The second point is the assessment of the area of the treated surface. The larger the area, the wiser to choose a dense composition, which does not require more than two layers. This saves both costs and effort.

- The third point is variable: the choice of a primer according to its function or the type of base to be treated. And in this regard, painters recommend using one simple rule: the primer, by the type of base, should be as complementary as possible to the surface material. If this option is unlikely, then the finish should be matched on the base with the base of the primer.According to this principle, mineral bases are selected for materials of natural origin, synthetic - for synthetic, silicone paints for silicone primers, alkyd paints - over alkyd primer.

- Mineral primers are used on fresh lime, plastered (plastered), concrete, cement and brick surfaces. They may include gypsum, cement, limestone. For outdoor use, a water-repellent base must be used. For internal, so that the plaster does not get wet, you need a quick-drying one.

- For mineral plaster - an exclusively mineral primer that improves hygroscopicity, increases adhesion, dries quickly, vapor-proof and resistant to environmental conditions.

- For the treatment of previously painted materials, primers based on copper sulfate are intended. They work on the principle of "pickling" for dirty surfaces, after which you can immediately start painting.

- For weak, free-flowing, highly porous materials that easily absorb liquid substances, use a deep penetration primer with good adhesion. For example, quartz with water-dispersion additives, acrylic and silicone-based substances are suitable. Before using enamels for decorative finishing, highly porous substrates are treated with deep alkyd compounds. If the top layer does not hold firmly, crumbles, cracks, a strengthening primer is needed.

- For metal substrates, it is recommended to use anti-corrosion treatment based on alkyd, epoxy, phosphate, glyphthalic bases. Mono-component and diluted formulations are suitable.

- An adhesion matte primer is also good. It is usually used locally for furniture, windows, doors. It is possible on combined surfaces, as it creates the ideal roughness for adhesion, even on glass, plastic, aluminum and other difficult types. You can dilute a dry mixture before use or use a ready-made one.

- For combined wood-metal bases, it is important to use a liquid suspension of alkyd components, desiccant, stabilizers and solvent.

- Wooden surfaces are impregnated with antiseptic agents that penetrate deep into the material. To protect against resin, the places of irregularities and twigs are treated with "epoxy". It is undesirable to mix them. After assessing the condition of the base, you need to choose a more suitable one.

- The finish of the wood is carried out with a lacquer primer.

- For not solid wood, but materials made from its fibers and adhesives, light acrylic primers are recommended. They are suitable for processing non-laminated plywood and chipboard, OSB, fiberboard and composite materials. They cope with the task, even if paint was previously applied to the tree.

Tips & Tricks

One of the advantages of the primer is its ease of use. But even though the procedure does not require special intricacies, it will meet expectations 100% only if used correctly.

Professional painters advise you to follow a number of simple rules:

- Surface preparation is a mandatory step. In the case of an old base that has already undergone one or more repairs, the previous layers of decorative coating must be carefully removed. For this, special solutions, paint removers, brushes, scrapers, water are used. After removing the remnants of the material, the surface is washed and dried.

- New walls, floor and ceiling only after completion of construction require less effort. They must be dedusted and degreased. A vacuum cleaner and wet cleaning will help to remove dust, and you can get rid of fat using a special composition or water with laundry soap. Then the surfaces are allowed to dry well.

- Compliance with safety measures. The primer is a harmless product, but if it gets on the mucous membranes and skin, it can cause irritation and an allergic reaction.Works are carried out in simple equipment. It is advisable to protect your hands with gloves, your head with a scarf, and your face with a respirator. Avoid eye contact when processing ceilings.

- Protect surrounding surfaces. The primer creates a dense film coating, sometimes colored, and if you do not protect the floor covering or decorative objects, then after drying, traces will remain on them.

- Correct selection of tools for different types of surfaces. The most popular tool for treating walls is a synthetic brush. It does not absorb the product, it allows you to work out all the cracks and hard-to-reach places. Large, flat areas are convenient to roll, but it absorbs a lot of liquid wasted. For the most even and thin layer, a spray gun is used.

- The ceiling is primed with a long handle roller. You can not use it while standing below so that the product does not get into your eyes, hair, or skin. For painting work, you need to get a stepladder.

You will also need a paint bath slightly wider than the width of the roller with a ribbed inclined surface to remove excess product. You need to roll the roller strictly in one direction, leaving no gaps. The second layer is applied perpendicular to the first. It is unsafe to prime using a spray bottle, since the substance will settle from top to bottom in the process, and it is simply inconvenient to work with a brush.

The tools for processing are the same as for walls, but the brushes are wider in size, and a foam roller is desirable. Synthetic brushes are used in the form of wide brushes, flat for painting in hard-to-reach places, radiator for the same purpose.

The rollers are suitable for priming the subfloor and for finishing wood flooring. Short and long nap tools work best on the subfloor prior to tiling and screed installation, but are not suitable for surface finishing due to unsightly nap stripes. Soft cylindrical rollers (fleece, foam rubber) and corner rollers are universal for difficult places. A spray bottle is not suitable as the floor primer is more viscous and quickly clogs the spray bottle.

- Do not use a product that has expired. It will be difficult to remove it from the surface and the primer will no longer give a uniform film coating.

- It is possible to apply paint, whitewash, liquid wallpaper and other materials only after the primer has completely dried. This is 24 hours or more, despite the performance from the package. The outer layer may seem dry, but 10-15 millimeters of the composition in depth must still dry.

- A heat fan or heater can help speed up drying. Drafts and humidity in the room must not be allowed until the primer is completely dry.

- It is easy to check its readiness for further work - with a piece of masking tape. It will not stick to a wet surface, but on a dry surface it will adhere well and remove without a trace.

- For paints with low hiding power, it is better to use the most similar color.

- Wash tools between the first and second coats. The film will dry on them, as well as on the treated surface. If not washed, they can be wrapped in a damp cloth and placed in a plastic bag.

Manufacturers and reviews

Primer production is a very developed niche today. Dozens of manufacturers offer their products for different purposes and at different price points. The rating of manufacturers in the domestic market, compiled on the basis of numerous reviews, will help to make the right choice.

- Bolars trade mark. It is a domestic manufacturer specializing in dry building mixes. Products are manufactured using high-tech equipment, quality control at all stages of production, and comply with safety standards.Importantly, reviews of those who have tested the primer indicate that its quality is superior to more expensive counterparts.

In the line of primers there are narrow-focusing agents - for unglazed tiles, grouting joints, glass. They provide moisture resistance and a glossy finish. Anti-mold products and concrete contact deserve special praise.

- Knauf company. Customer reviews confirm that the brand's products are famous German quality at a competitive price. Primers cope with difficult tasks such as treating old walls, wood, crumbling and porous surfaces.

The assortment of Knauf finishing materials is very wide, and there is a primer for any type of work. Separately, formulations are produced for all types of paints, for processing ceiling surfaces, for walls, under floor screeds, including leveling mixtures.

Noteworthy are the universal primers that Knauf produces in predominant quantities. The disadvantage of the product is that the ideal combination of the primer is given only with the finishing materials of the same manufacturer. And they cost an order of magnitude more expensive than materials of other production.

- German brand Vetonitwith branches in Russia. Manufacturers give a guarantee for all products, regardless of what surface (walls, floor, ceiling) it is intended for, and in what condition the surface is. Due to the excellent penetrating, adhesive, waterproof and antibacterial qualities of the primer, it is in demand in special cases of repair and in mass construction by professionals.

- Firm "Lakra" is practically on a par with the German concern. For over twenty years she has specialized in the production of alkyd and acrylic primers. They are not intended for finishing, but they are most effective as a base for other materials. Separately, it is worth highlighting a black primer for metal surfaces, which several times improves the adhesion and resistance of the material to the negative effects of moisture. Good and versatile deep action primers.

An indisputable plus of the products is that it is possible to purchase a concentrated water-soluble primer, which allows you to save a significant amount, since it turns out 5 times more funds than when buying a ready-made one for the same money. According to reviews, the primer "Lacra" is a product that meets expectations, and from professional painters it often goes into the category of systematically purchased.

- Brand Tikkurila - one of the recognized leaders in the market of paints and varnishes. Since the paint is designed for completely different surfaces, then the primers are very diverse. Those who have tested them in practice, unanimously recognize the best primer in the line for wooden surfaces, including sheet material of fiberboard, MDF and chipboard. There are also solutions for complex surfaces: glass, aluminum, plastic, ceramic tiles, steel, as well as a primer for processing ferrous and non-ferrous metals, soluble with white spirit. Customers of Tikkurila products confirm that when used in conjunction with paints, an advertising-like effect is achieved.

- As the Finnish primer is designed for harsh climatic conditions and British manufacturer Dulux knows a lot about moisture-resistant materials for facade processing. You can work with such a primer in damp and cool weather. It perfectly protects wood from rotting, and metal from corrosion.

- Primer "Tex". Amateurs recognize this product as worthy in terms of quality, price, ease of application and the achieved effect. But professionals are not always satisfied with even concentrated substances of the "Profi" series. They consider the price of this product somewhat overpriced, and the manufacturer's promises embellished.

- Some professionals contrast the Tex primer production of "Ceresit". Judging by the reviews, her penetrating ability is better, and the covering ability is higher, and the quality is more reliable. Suitable for various indoor and outdoor surfaces.

- Less demanded primers Axton, Bergauf, Eunice, Osnovit, Aquastop and others... The opinions on their quality were divided. Some believe that this is a decent quality at an affordable price, others argue that it is water and chalk, and the only advantage of the purchase is a convenient container.

Successful examples and options

Applying a primer is a necessary stage of interior and facade finishing. This has long been proven in practice by successful examples. So, the primer is a universal tool for applying on porous surfaces, processing bricks, cement, foam blocks, glass, metal, wood, cork.

It is needed to protect the polymer dry backfill and floor screed, it is indispensable for increasing the adhesion of glass to the finishing material, protecting water-based paint, strengthening the finish on old paint, plaster or putty. Separately, it is worth highlighting the less common types of primer - finishing, varnish, protective for unglazed tiles and grouting joints between tiles.

For the types of primers, see the video below.

The comment was sent successfully.