Silicone sealant: pros and cons

During repair work, a situation often arises when it is necessary to cover up the gaps between various surfaces, achieve tightness or seal holes. Very often, such questions arise in the process of repairing a bathroom, toilet and kitchen, because in these rooms the percentage of humidity is the highest. The most reliable and modern method of sealing any crevices and holes, even in humid conditions, is silicone sealant.

Peculiarities

There has always been a need for grouting, sealing holes and grinding joints, but previously all kinds of putties were used for these works, which were not very convenient to work with, and the result was not always of a satisfactory quality. It is for these reasons that the search for a universal remedy has been carried out until now and has led to the emergence of a silicone sealant. With this tool, moisture does not get under the protected surface and does not allow it to collapse.

The scope of application of the sealant is very wide. With its help, you can seal the window frame, cover up cracks between the bathroom and the tile, even use it to eliminate possible water leaks from plastic pipes. All this is possible due to the specific composition of the product. To make a silicone adhesive sealant, you need to use silicone rubber, which is the basic element, reinforcers, which will give the finished material strength after application. In addition, you need a vulcanizer that makes the composition liquid and viscous, an adhesion primer for better contact with the working surface, a plasticizer to impart additional elastic properties and a filler that allows you to obtain the desired volume and color of the sealant.

Sealants differ depending on the vulcanizers they contain.

- Acidic adhesives. A distinctive feature is the unconventional smell that acetic acid imparts. It is best not to use this sealant on marble, aluminum and cementitious surfaces. When working with it, it is important to use protective equipment and masks, because the fumes are very toxic and cause dizziness and allergies.

- Neutral sealant. There are several options for such a solution: alcohol, amine and amide. In this case, there is no strong smell. Can be used on various types of surfaces.

Sealants are:

- single-component - find their application in the domestic sphere;

- two-component - characterized by the presence of complex components in the composition, they are most often used in production.

The characteristics of the silicone sealant make it possible to use it on a wide variety of surfaces that can have a heterogeneous structure.

Their properties include:

- resistance to frost and moisture, easily withstand temperature extremes;

- have increased adhesion, they are well connected with various kinds of details;

- easily tolerate ultraviolet rays;

- high level of plasticity;

- high heat resistance, application is possible in conditions from +300 degrees to -50.

You can use this tool both indoors and for outdoor work.

If you need to do something in the house, then the sealant can be used to:

- sealing joints on walls, ceilings, floors, especially when working with drywall;

- sealing joints on countertops, window frames, where natural or artificial stone is used;

- sealing parts with high thermal stress;

- in the bath, you can use it for mounting a mirror, sealing pipes for sewage, eliminating joints during the installation of a bath or shower stall.

Use silicone sealant for outdoor use:

- imparting tightness to gutter pipes;

- sealing seams on window frames and joints;

- carrying out repair work with stone tiles that move away from their base;

- sealing seams during roofing;

- in the vinyl cladding process.

The production technology of the sealant is rather complicated and it is not so easy to achieve that it has the appearance of rubber, while being able to be liquid and easily penetrate into various cracks, eliminating them, but it allows you to make repairs of much higher quality, and the result is much more representative.

There are many options for such products today, and it can be difficult to choose the most high-quality and suitable type. You can buy a universal sealant "Econ" or buy a sanitary version "Moment", it all depends on the specific case and the task that is set for the tool.

Advantages and disadvantages

If we consider silicone sealant as a tool without which it is now difficult to do in repairs of varying complexity, then it is necessary to indicate all its advantages and disadvantages.

Consider the pros of a sealant.

- Prevents mold and insects from spreading on surfaces. This is made possible by the fungicidal additives that are included in its composition.

- After complete drying, it is not afraid of the effects of cleaning agents, even chemical ones.

- With the help of a sealant, it will be possible to bond different types of surfaces. Silicone is the best choice for joining ceramics, glass, plastic, wood, rubber with other materials.

- High strength of the material after drying, even with a liquid and elastic structure during application. This is achieved by the presence of silicon in the composition.

- The peculiar composition allows the already glued surfaces to be mobile and elastic.

Despite such a large number of advantages, there are significant disadvantages to silicone sealant.

- There are a number of surfaces that are poorly connected with a sealant - these are polyvinyl chloride, fluoroplastic, polyethylene, polycarbonate and polypropylene.

- For application, the surface must be completely clean, therefore it is cleaned, degreased and completely dried. When applied to a damp surface, the properties of the material deteriorate significantly.

Acrylic and silicone sealant have some differences, and first of all, their difference is in the composition: for silicone glue, rubber is important in the composition, but for acrylic it is acrylic acid. Silicone sealants are used to work with plastic, wood and ceramics, and the acrylic variety is versatile. With the acrylic option, you can sand it down to get a completely flat surface that can be painted over. However, there is a stronger shrinkage and in the solidified form the material is not so elastic. This type is used for internal work, because with a large amplitude of the temperature regime, it can deteriorate.

Silicone sealant provides better adhesion to even and smooth surfaces, it is not afraid of compression and kinking. In view of this, the cost of this option is more expensive than acrylic. Both material options can be both transparent and colored, which are used in different situations.

Since silicone sealants can be one- and two-component, it is important to understand the differences and in this case, identifying certain advantages and disadvantages of each of the options. One-component composition is found most often, it is it that is used for all construction work by both professionals and amateurs. The ease of working with it determines the popularity of this material.The scope of use of the sealant is constantly expanding. So, it can be used not only in home renovation, it is also great for working with the machine, eliminating any seams, cracks and joints, it can be used to isolate electrical equipment, and in some cases it is used as a protective layer from moisture.

Two-component silicone is used in manufacturing and industry. The composition is much more complex, because it combines various elements. It is not used for everyday repair tasks.

Consumption

In order for the repair to be done efficiently and all the seams and joints are smeared beautifully and reliably, it is important to know exactly how it needs to be applied and how much material to use. When calculating the most correct consumption of sealant per 1 m of the joint, you need to know its thickness and application technology. If we are talking about the fillet weld between the bathroom and the tile, then the best will be a depth of 6 mm and a width of 3 mm. Using such calculations, 20 ml of material will need to be used per square meter. Often 310 ml in a standard package, and in order to apply it correctly and economically, it is best to be guided by the indicators that the table gives:

Joint width in mm | |||||||

Joint depth in mm | 5 | 7 | 10 | 12 | 15 | 20 | 25 |

5 | 12 | 8 | 6 | - | - | - | - |

7 | - | 6 | 4 | 3 | - | - | - |

10 | - | - | 3 | 2.5 | 2 | 1.5 | - |

12 | - | - | - | 2.1 | 1.7 | 1.2 | 1 |

15 | - | - | - | - | 1.3 | 1 | 0.8 |

In the event that a 600 ml package was selected for work, then the calculations will differ for 1 m of the seam:

Seam width | |||||||

Seam depth | 5 | 7 | 10 | 12 | 15 | 20 | 25 |

5 | 23 | 15 | 11 | - | - | - | - |

7 | - | 11 | 7 | 6 | - | - | - |

10 | - | - | 6 | 5 | 4 | 3 | - |

12 | - | - | - | 4 | 3 | 2.4 | 2 |

15 | - | - | - | - | 2.5 | 1.9 | 1.4 |

For a more economical use of the sealant, it is better to apply a semicircular seam, which is possible when working with a spatula with an edge of 6 mm, in addition, it is very important to correctly cut the spout of the tube itself, where the material will come from. To do this, you need to put a spatula to the spout at an angle of forty-five degrees and open the package.

Colors

The popularity of silicone sealant has caused the need to expand its types and the emergence of a wide variety of variations in both composition and color.

Based on the external characteristics, several can be distinguished.

- Colorless. It is most often used in working with plumbing, if you need to remove seams or connect elements. You can use it when installing new furniture in the kitchen, treating unprotected surfaces where moisture can get.

- Colored silicone. It has a characteristic composition, due to which it does not stain afterwards, therefore it is necessary to buy a product already with a certain pigment. Most often, you can find white, gray, beige, brown and other options on store shelves.

In addition, depending on the scope of use, a number of sealant options are distinguished.

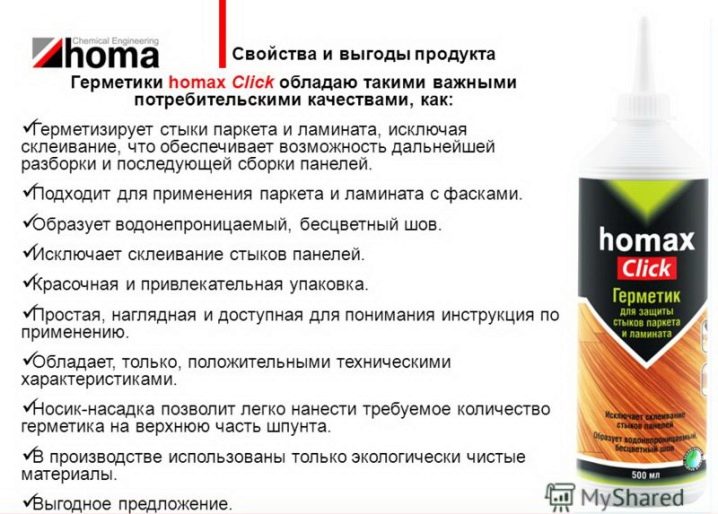

- Bituminous. With its help, you can cope with cracks in the basement and foundation, eradicate damage to tiles and slate. Can be used with a wide variety of surfaces. This is a moisture resistant option that is not afraid of temperature extremes and has good adhesion.

- Universal. With its help, you can eliminate drafts from the window, using glass during installation in a wooden frame. For outdoor use, it is best to use a colorless sealant to make it less visible on the wood.

- Aquarium. It has no toxic elements in its composition. Flexible and resilient, highly adhesive, water resistant and dries quickly. It is used to work with shower cabins, ceramics and glass products, for fastening parts of the aquarium.

- Sanitary. It is used in rooms with a high level of humidity. A distinctive feature is the presence of antifungal and antibacterial components.

- Heat resistant. Used in industry. The main purpose is the assembly of pumps, motors, furnaces, sealing heating pipes, during electrical work.

Since the scope of use of sealants is very large, it is important to choose the right option for a particular type of work. If the surface needs to be painted later, it is important to choose either the appropriate type of silicone, or purchase it in the required color.The result of the work done will completely depend on the correct selection of funds.

How to apply?

In order to start working with silicone sealant, it is important to prepare and purchase everything you need. The first point will be protective clothing, which should completely cover the skin of the hands, and, if possible, it is better to wear a construction overalls and a long-sleeved sweater to protect the whole body. There are formulations with a more aggressive composition, for which it is advisable to use a protective mask on the eyes and nasopharynx.

The second stage of preparation will be to obtain the necessary knowledge, with the help of which it will be possible to quickly and correctly do all the necessary work.

Sequence of work.

- Preparation of workwear and necessary materials.

- Working with the surface to be applied with the sealant. It is important that it is clean, dry and fat-free. If there are decorative elements, it is better to hide them under masking tape to prevent silicone glue from getting on the surface.

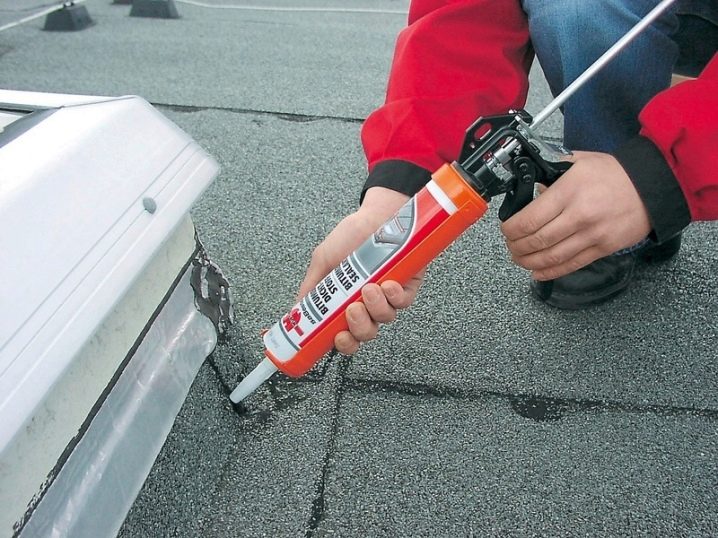

- To use the sealant, you will need an assembly gun to make application easier. For correct installation and operation, simply read the instructions on the package.

- The tip of the spout on the sealant bottle must be cut obliquely. This option allows the material to drain evenly and economically be used in the work. If you cut off an even edge, then the shape of the flowing substance will be round, and with an oblique cut it will be elliptical, which will minimize the waste of excess material.

- The silicone is applied to the surface when the balloon is at a 45 degree angle. Application is in thin stripes to allow the glue to dry faster. After finishing the application, the remnants of unnecessary material must be removed with a spatula.

The drying time depends on the type of adhesive that has been selected and the thickness of the layer that has been applied to the surface. It usually freezes completely in a day, and the first signs of hardening are visible after twenty minutes. When applied to the surface of chipboard and fiberboard, it is better to use a spatula and squeeze out a very small amount of the substance. If there is a goal of creating a perfectly flat surface on these surfaces, then the sealant is best diluted with gasoline or white spirit, the amount of which should be small.

In order to more accurately understand what exactly has to be done with the sealant, the first thing you should pay attention to is the instructions on the package. Most often, manufacturers indicate everything that a worker needs to know when interacting with a silicone product. If the quality of work is extremely important, then before buying a sealant, you need to pay attention to the timing of its manufacture, and if they are stitched, then it is better not to purchase the product.

If the choice is made correctly, then working with silicone glue will be quite simple and comfortable. As soon as the required amount of the product has been applied to the surface, it is important to ensure that all excess is quickly removed. This can be easily done with your own hands, but it is important to know the sequence of actions. White spirit is best for fresh solutions, but you need to make sure that it is safe for the surface itself. If this is the case, then as soon as possible it is applied to the area that needs to be cleaned, and all excess is quickly removed.

There is another very effective tool that allows you to wash off the silicone from the surface, this is "Penta 840". Using this option will allow you to simply dissolve the sealant, even if it is dry. The simplest, but no less effective, is the use of a soap solution. After moistening a rag in it, it is necessary to evenly apply it to the surface to be washed off.

The most dangerous for the coating will be the use of a knife or putty knife, with the help of which the dried silicone is removed from the surface. You need to use these funds very carefully and without undue haste.With the help of solvents, it will be possible to remove only fresh or thin areas of silicone, and for denser ones, you need to use a mechanical option.

Manufacturers

Any tools and materials for repair work can have a different price, which depends on their quality and the brand that they produced. If there is an opportunity to buy a more expensive option, then it is more likely that the result will be an order of magnitude better than using the cheaper one.

In order to navigate among silicone sealants and help you choose the best option, it is necessary to make an overview of the most famous manufacturers that have been on the market for a long time and have established their products as high-quality and durable.

Among the most popular are Makroflex, Ceresit, Tytan, Soudal, Krass, Ultima, Penosil and Titan.

Makroflex - these are products from Finland, they are characterized by their use in the most difficult and difficult conditions. The line includes both sanitary, neutral and universal sealants.

Sealants Tytan are produced by a Polish company that presents high quality professional products at competitive prices. If it is necessary to work in rooms with high humidity, it is necessary to use Ceresit CS 25 sealant, where, among other things, there is a large amount of fungicides that prevent the formation of mold and mildew.

If we talk about products Krass, then it is produced in Switzerland, Finland and other countries, where great attention is paid to a quality product. These products are marketed in four varieties: acrylic, heat-resistant, silicone and neutral sealant. This option is used for working with concrete and stone, as well as for metal surfaces. Well suited for work in the kitchen and bathroom. The products of this company are characterized by good adhesion, resistance to aggressive environments, elasticity, frost resistance and thermal stability, they are used from -50 to temperatures above 1000 degrees, in addition, the sealant is resistant to ultraviolet radiation.

When it comes to acid sealant Ultimathen it is suitable for a wide variety of construction work. Due to its good adhesion, it interacts well with glass, wood and ceramics. It can be used both inside and outside the building. It is produced in a tube with a volume of 280 ml and in black, gray, transparent, brown, white and beige. The main characteristics are elastic composition, moisture resistance, resistance to ultraviolet rays, economical packaging that does not require the purchase of a pistol.

Penosil is a one-component substance that allows you to seal and seal joints both indoors and outdoors. It has good adhesion to metal, glass, ceramic, wood surfaces treated with varnish or paint, with plastic and more. It has a dense structure, which allows it not to spread or slip during application to the seam. It sets quickly and is covered with a film. It is resistant to atmospheric changes and ultraviolet radiation.

Each option is versatile in its own way, the sealant allows you to achieve the best results in all areas of application. High-quality and reliable companies allow you to be sure of the result even at the stage of purchasing materials, and further work will depend on the skill of using the silicone sealant.

Tips & Tricks

In order to buy a good sealant, it is important to pay attention to some characteristics, such as:

- the percentage of silicone in the composition should be 26;

- the percentage of rubber organic mastic can range from 4 to 6 percent;

- the percentage of triokol, polyurethane and acrylic mastic should be within 4 percent;

- epoxy content should not exceed 2 percent;

- and cement mixtures should be less than 0.3 percent.

If we are talking about the density of the sealant, then it should be no less than 0.8 g / cm, otherwise the composition is of poor quality. If in the work you need to use a sealant for the food zone where food is located, then in no case should you use an antimicrobial and antifungal sealant, this also applies to work with an aquarium or terrarium. If there is a need to close up small gaps in the windows, then it is best to choose a sealant for external work, which can be easily applied without wiping off the drips and without worrying about the quality of the material if it is exposed to sunlight and moisture.

When the sealant is applied to the surface, it is important to level it, for this you can use both improvised materials and a soap solution. If you wet your finger in it and run it over the silicone, you can get a flat and smooth surface. The acrylic sealant can be painted after hardening. Not all silicone options are subject to staining, so you should pay attention to this when buying.

For wood, it is recommended to use transparent silicone, which will not be visible after drying. For working with the floor, choose dark color options that do not stand out when dry. In order to quickly dry the sealant, it is best to apply it in thin layers and not in large quantities. You can erase the excess both with liquid products and by machining with a spatula and a construction knife.

When buying silicone, it is important to look at the documentation that comes with the product, so you can get an idea of the brand, quality and production time.

In the event that there is a need to obtain a special form for imprinting a particular material, you can use silicone molds. To make them, you will need to take silicone sealant and potato starch. With proper mixing, you get a composition that hardens well and quickly and makes it possible to obtain the desired cast, which will help in some types of repair work.

For information on which silicone sealant to choose, see the next video.

The comment was sent successfully.